What you're getting with the API Toolbox

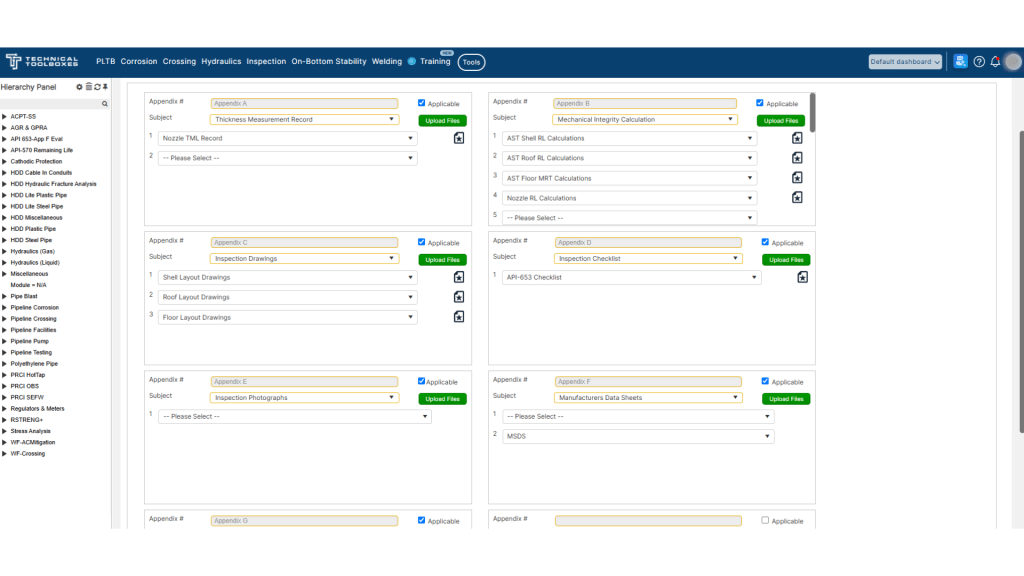

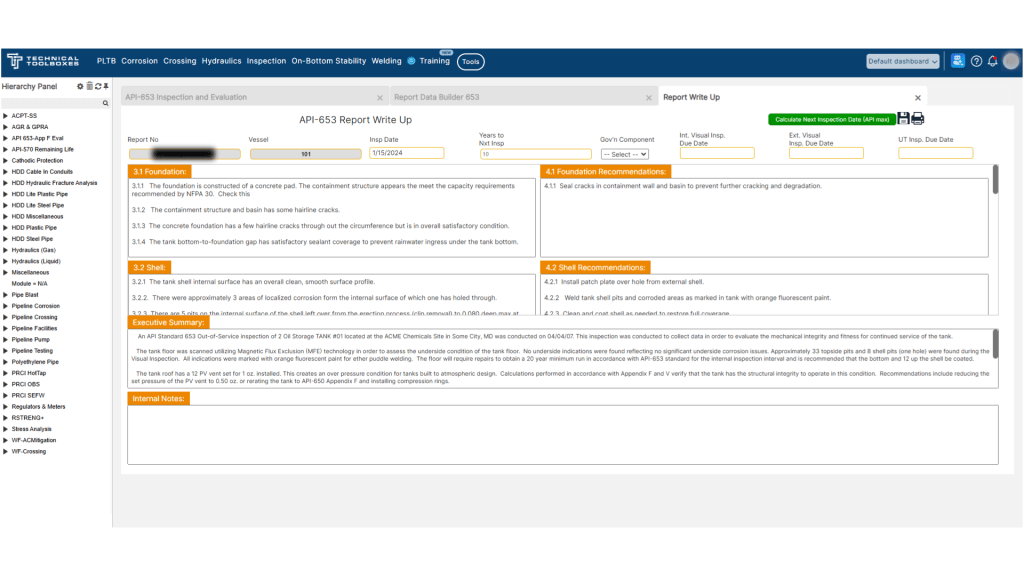

Report Accuracy

Report Accuracy

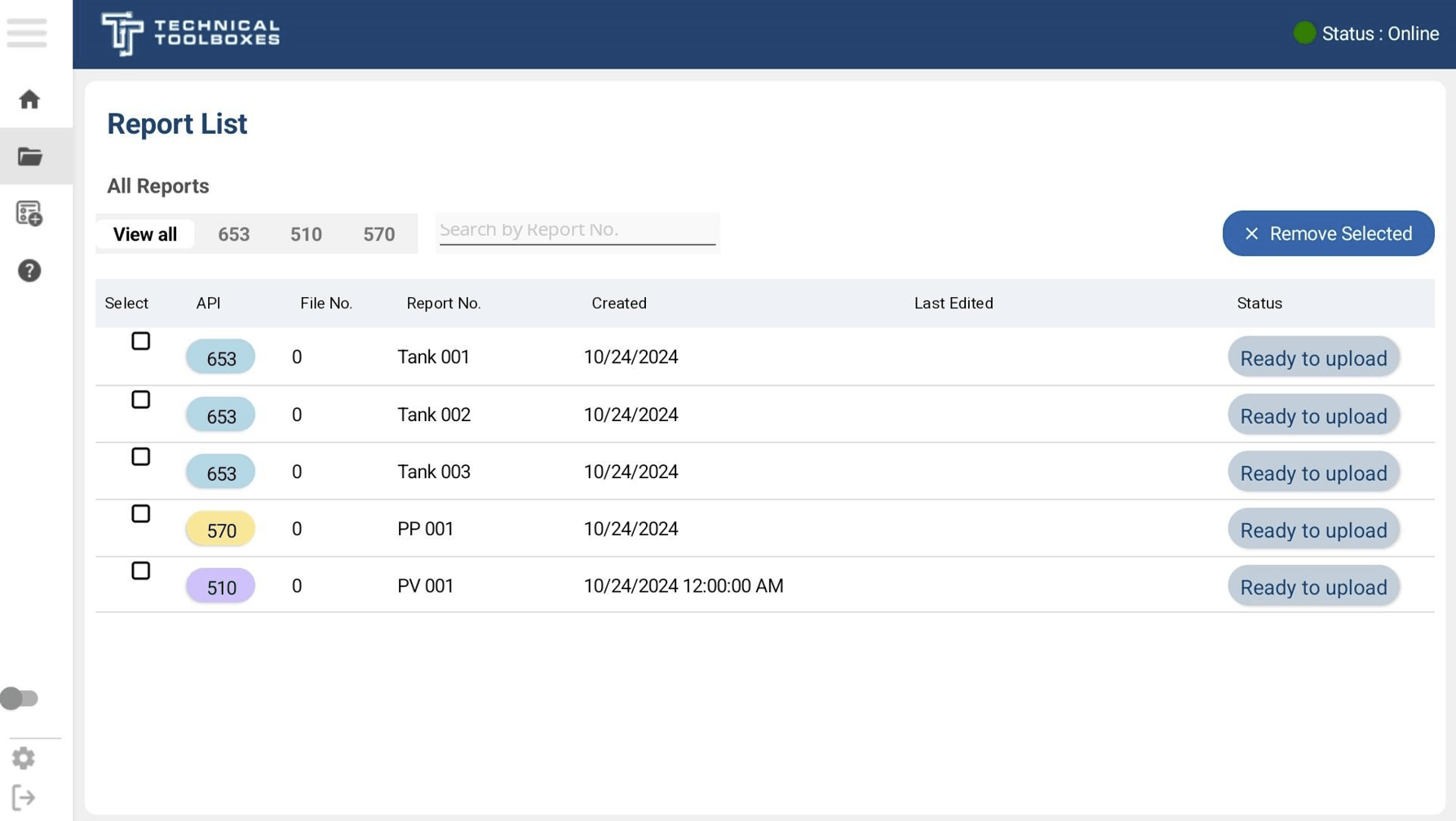

Data Automation

Data Automation

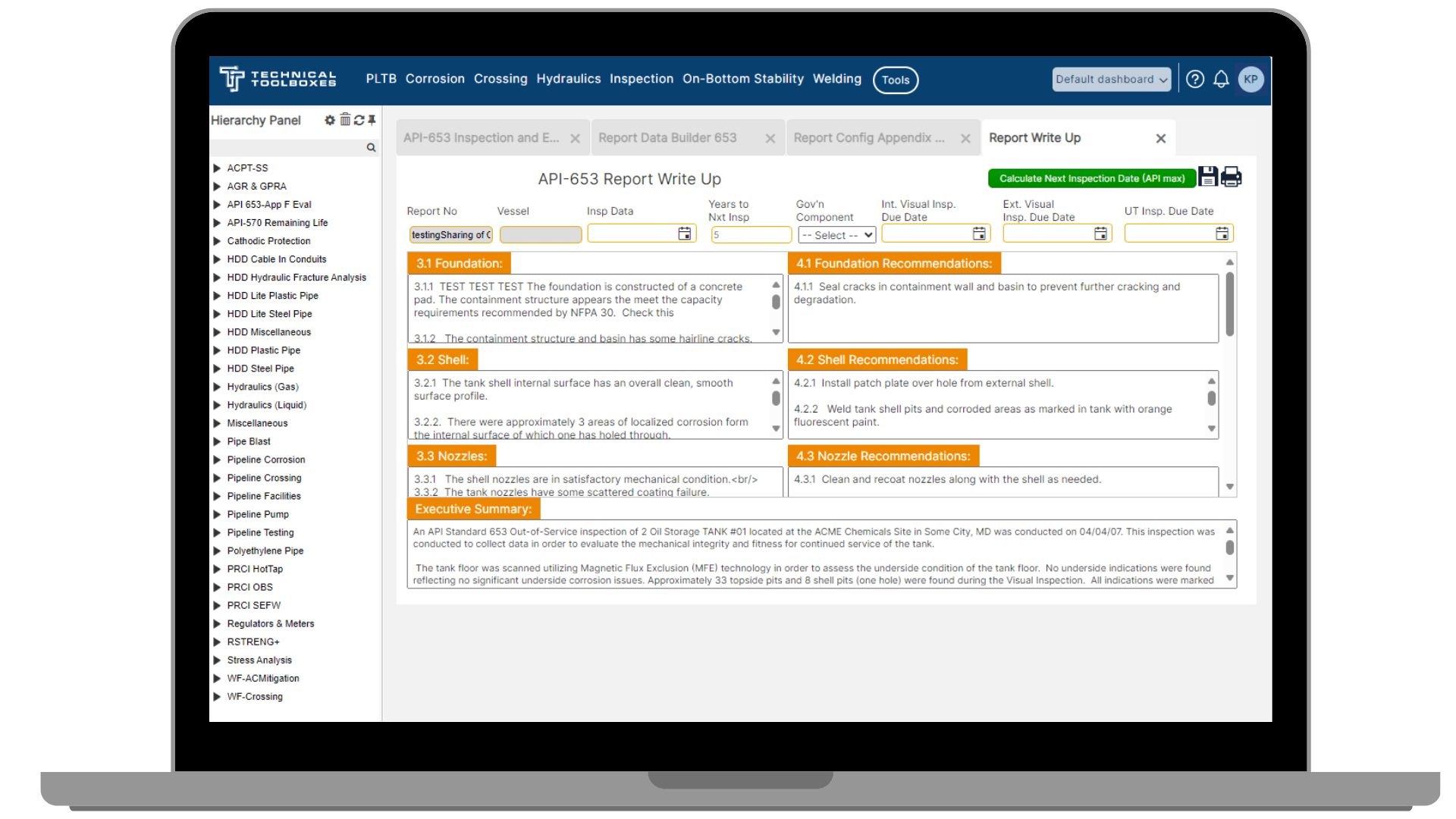

Advanced Reporting Tools

Advanced Reporting Tools

API ROI Calculator

Estimate your potential time and cost savings with the API Inspectors Toolbox.

Calculate your estimated annual ROI based on inspection volume, labor, and reporting needs. Built using real-world inputs from inspectors and asset owners, it shows how modernizing your API inspections with APITB can impact your bottom line.

Estimated Annual Savings

Disclaimer:

The estimates above are based on actual customer feedback and industry averages. Results are not guaranteed and will vary depending on your organization’s size, processes, and use of the platform. For a customized ROI analysis, please contact [email protected].

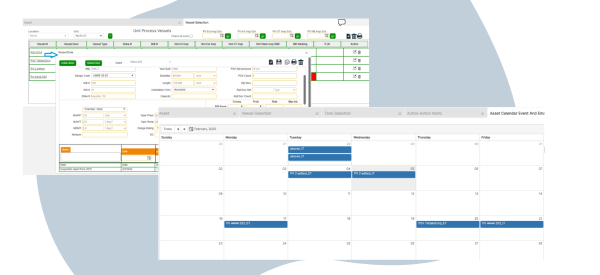

Introducing the API Collector App

Download the API Collector App and transform your in-field data collection process: experience faster, more accurate reporting right from your tablet.

Why Choose the API Toolbox

Why Choose the API Toolbox