Applying PRCI Thermal Analysis Model using API 1104 and Colebrook-White Equations in Pipeline Engineering

By Joe Pikas

Pipeline engineering requires precision, adherence to standards, and the use of robust equations and methodologies to ensure the integrity and safety of pipeline systems. Two critical aspects of this are the application of PRCI Thermal Analysis Model using API 1104 welding standards and the Colebrook-White equation for fluid flow calculations. In this educational blog, we’ll explore how these are applied in the context of pipeline engineering.

Understanding API 1104 Welding Standards

API 1104 is a key standard that governs the welding of pipelines, particularly for ensuring the integrity of welds used in the transmission of gas and liquids. This standard is essential for pipeline engineers to understand and implement correctly to avoid potential failures in the field.

Key Aspects of API 1104:

- Weld Imperfection Assessment: API 1104 provides a comprehensive guide on evaluating welding imperfections and determining their acceptability. This includes specific criteria for both gas and liquid pipelines, ensuring that each weld meets the necessary safety standards. Tools such as the PRCI Thermal Analysis facilitate the practical application of these standards, helping engineers assess weld quality accurately.

- Compliance and Safety: API 1104’s guidelines ensure that welds maintain the pipeline’s integrity, preventing leaks and failures from cracking that could lead to catastrophic incidents. Industry compliance with API 1104 is mandatory under various federal regulations, making it a cornerstone of pipeline welding operations.

The Colebrook-White Equation in Pipeline Design

The Colebrook-White equation is a fundamental tool in pipeline hydraulics, used to determine the friction factor in turbulent flow conditions. This equation is crucial for calculating pressure drops in pipelines, which is essential for designing efficient pipeline systems.

Application in Pipeline Engineering:

- Pressure and Flow Calculations: The Colebrook-White equation helps engineers calculate the necessary parameters to maintain optimal flow rates while minimizing pressure losses. This is particularly important in the design and operation of pipelines where precise control over fluid dynamics is required.

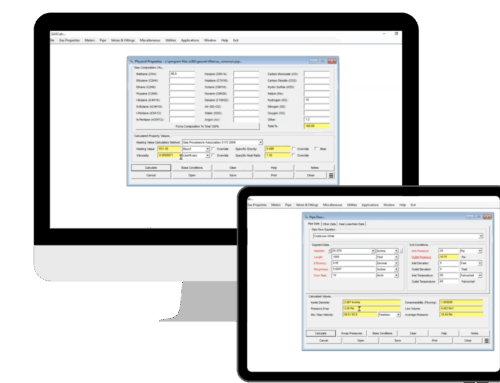

Integration with Pipeline Toolbox (PLTB): Technical Toolboxes’ Pipeline Toolbox integrates the Colebrook-White equation into its hydraulics module, allowing for detailed and accurate flow calculations. It will produce the greatest consistency of accuracy over the widest possible range of variables. This integration ensures that engineers can easily apply this equation across various scenarios, enhancing the reliability of their designs.

Integration with Pipeline Toolbox (PLTB): Technical Toolboxes’ Pipeline Toolbox integrates the Colebrook-White equation into its hydraulics module, allowing for detailed and accurate flow calculations. It will produce the greatest consistency of accuracy over the widest possible range of variables. This integration ensures that engineers can easily apply this equation across various scenarios, enhancing the reliability of their designs.

Best Practices in Applying API 1104 and Colebrook-White

To maximize the effectiveness of these tools and standards, pipeline engineers should follow these best practices:

- Regular Training and Certification: Engineers should regularly update their knowledge of API 1104 standards and ensure they are certified to apply these in their projects. This not only ensures compliance but also promotes safety across pipeline operations.

- Using Advanced Software Tools: Leveraging software like the Pipeline Toolbox and PRCI Thermal Analysis can significantly enhance the accuracy and efficiency of applying both API 1104 standards and the Colebrook-White equation. These tools reduce the risk of human error and provide a standardized approach to pipeline design and assessment.

- Consistent Documentation and Record-Keeping: Ensuring that all calculations, inspections, and assessments are thoroughly documented is critical. This not only aids in maintaining compliance with federal regulations but also facilitates easier audits and reviews.

Conclusion

The application of API 1104 welding standards and the Colebrook-White equation in pipeline engineering is essential for ensuring the safety, integrity, and efficiency of pipeline systems. By adhering to these standards and utilizing advanced engineering tools, pipeline engineers can effectively manage and optimize their projects, ensuring compliance and operational excellence.

For further details, you can explore tools like the Pipeline Toolbox and PRCI Thermal Analysis, industry compliant hot tap welding software, and explore the applications through Technical Toolboxes.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]