CP Design Parameters for Buried Pipelines

By David Willoughby

Cathodic Protection Design

There are several different approaches to designing a pipeline CP system. Each approach must consider the set of CP design parameters affecting the pipeline to be protected to help determine the type of system best suited for the specific case. These design parameters include (but are not limited to):

- Type and geometry of pipeline to be protected

- Electrolyte conditions (mainly resistivity, but also pH, chloride content, moisture content, and sulfide content)

- Type and quality of the pipeline coating

- Cathodic protection current requirement

- Presence of other pipelines in the area

- Presence of other CP systems in the area

Key Considerations in SCP and ICCP System Design

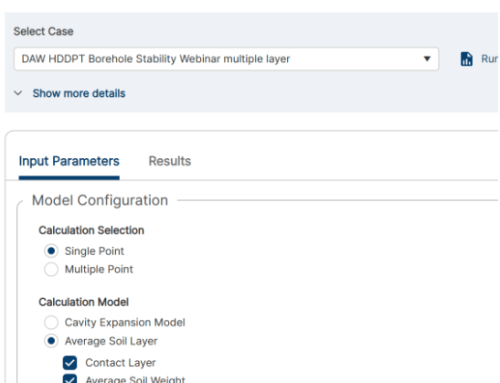

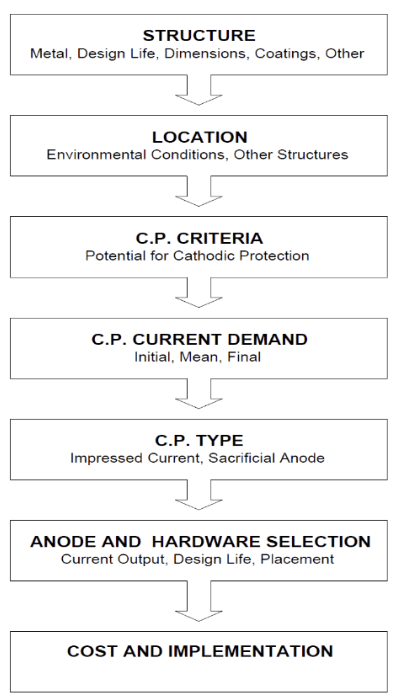

The general design procedure for both sacrificial cathodic protection (SCP) and impressed current cathodic protection (ICCP) systems are similar. A review of pertinent drawings and specifications for the structure being protected and for the site should be made to obtain information necessary for the design of a CP system. Actual conditions should be verified since structurally and operationally insignificant factors, such as contact between buried structures (shorts), can have a great effect upon the operation of a CP system.

The general design procedure for both sacrificial cathodic protection (SCP) and impressed current cathodic protection (ICCP) systems are similar. A review of pertinent drawings and specifications for the structure being protected and for the site should be made to obtain information necessary for the design of a CP system. Actual conditions should be verified since structurally and operationally insignificant factors, such as contact between buried structures (shorts), can have a great effect upon the operation of a CP system.

First the amount of protective current is determined, then the best means of applying the current to the structure is established. In many cases both SCP and ICCP systems are feasible, and an initial approximate design is prepared for each type of system to select the most appropriate type of system for the application.

Structure Size, Material, and Coatings

The size, shape, material, and surface condition of the structure to be protected must be established to design an effective CP system. The size and shape are usually established by the appropriate drawings for the installation. The material and surface conditions, particularly the presence and quality of protective coatings, are usually established by the specifications for the installation.

For a previously installed system, the condition of the protective coatings may be established during a field survey. A site drawing including all other metallic structures in the vicinity should also be reviewed to establish the presence and locations of other structures which may affect the operation of the system being designed. The presence of other CP systems in the area should be particularly noted as the installation of an additional CP system could affect the operation of existing systems.

Soil Resistivity and Moisture in Buried CP Systems

For buried systems, soil characteristics must be defined to establish the requirements for protection. Sulfide, sulfate, chloride, pH, and other chemical constituents will affect the current requirements necessary for protection and protection criteria for some materials. Soil resistivity is the single most important characteristic used in the design of CP systems for buried structures. Protective current requirements, sacrificial anode outputs, and impressed current anode bed resistance are all dependent upon soil resistivity. Soil corrosivity and soil resistivity are closely related with the highest corrosivity being associated with low soil resistivity soils.

Without moisture the usual electrochemical reactions of corrosion and CP cannot occur. For example, solidly frozen water prevents ion migration and ice becomes very high in resistivity. Likewise, although uncommon, a totally dry soil will not transfer charge. Moisture may not only contain soluble chemical compounds that provide ions for charge transfer, but it may also contain dissolved oxygen that influences polarization, and other gases such as carbon dioxide and sulfur dioxide that lower pH.

Impact of Soil Texture and Aeration

Soil texture (particle size) is important in that it influences how readily liquids and gases can permeate the soil. Differences in soil texture can create differential aeration cells that can be very corrosive. Those areas that are deficient in dissolved oxygen become anodes with respect to aerated locations. Dense clay and silt promote anaerobic conditions suitable for the development of certain microbiological forms that produce aggressive corrosion. Increased temperature has a depolarizing effect because of the increased rate of diffusion of reducible species to the cathodic sites, and a decrease in concentration polarization. Consequently, the rate of the reduction reaction is increased, thus decreasing the level of polarization and increasing the CP current requirement. The oxygen content or other oxidizers increase the current requirements because they flatten the cathodic polarization slope. Therefore, structures in well–aerated soils, such as sand and gravel, require more CP current than structures surrounded by relatively de-aerated soils, such as clay.

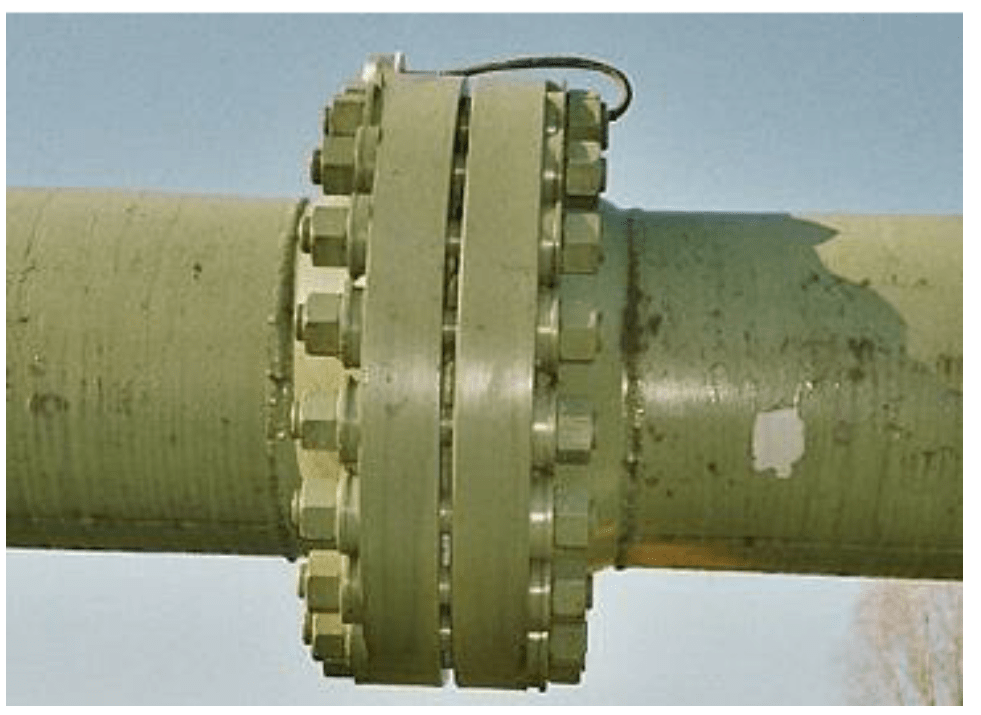

Coatings and Electrical Continuity in Cathodic Protection

The buried pipeline structures have a significant influence on CP. Some of the important considerations are the construction materials, fabrication methods, pipeline geometry, pipeline protective coatings, electrical isolation from other structures, and electrical grounding requirements. Electrical continuity and lineal resistance are important factors in the CP design for pipelines. Mechanical joining may produce electrically discontinuous connections of one pipeline component to the next. Threaded pipe and pipes joined by bolting or mechanical couplings often develop significant amounts of linear resistance in a pipeline. Mechanical joints may even act as electrical isolation joints. When designing a CP system for pipelines it is important that electrical continuity be established between all the pipeline components. If sections of the pipeline are not electrically connected, they will not receive protective current and may be subject to corrosion.

Protective Coatings

Pipeline coatings are not the perfect answer to corrosion control. However, they are an extremely effective weapon when properly used. A properly selected and applied coating will provide all the protection necessary on most of the pipeline surface to which it is applied. On a typical well-coated pipeline this should be better than 99 percent. Good practice in modern pipeline corrosion control work comprises the use of good coatings in combination with CP as the main lines of defense. The importance of protective coatings in the design of cathodic protection systems cannot be overemphasized.

More on Corrosion Information

For more information regarding this blog topic, read our Cathodic Protection Criteria and Current Requirements for Buried Pipelines blog or join us in a self-paced training on CP Circuits and Types of Corrosion. You can also contact me, the author, David Willoughby, at [email protected]

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]