Fixing the API Inspection Bottleneck: Faster Reports, Stronger Compliance

By Jeff Walling

The Challenge: Balancing Fieldwork and Reporting

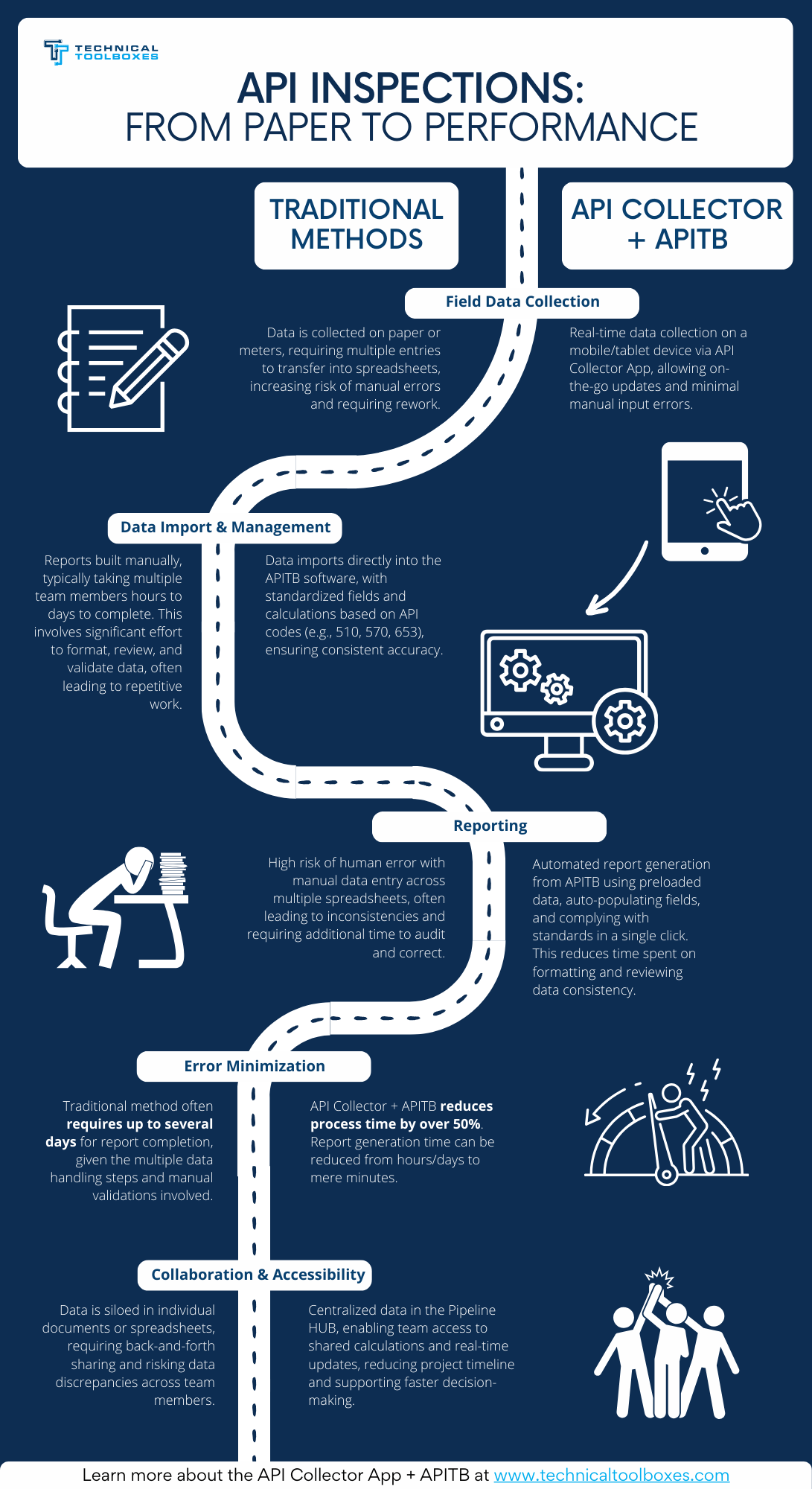

For growing inspection companies, the biggest challenge is balancing time in the field with the extensive effort required for reporting. Typically, inspectors spend one day in the field and require two to three days to complete reports. This imbalance becomes even more pronounced when dealing with multi-certified inspectors, whose demand for fieldwork leaves even less time for reporting. The result? Backlogs, delayed reports, and frustrated clients.

The API Inspector’s Toolbox (APITB): A Smarter Solution

The API Inspector’s Toolbox (APITB) is designed to streamline inspections, evaluations, reporting, and asset management by offering:

✅ A field data collection app for efficient, real-time data entry

✅ Easy-to-follow workflows for API-653, API-570, & API-510 reports

✅ Easily accessed engineering material & calculations for components for AST’s, PV’s & Piping

✅ An integrated asset tracking database to keep inspections organized

Inspections can flow smoothly with fewer bottlenecks. Read the API Inspection Roadmap to learn more.

Key Bottlenecks in API Inspections & How APITB Solves Them

1. Reducing Manual Data Entry & Report Compilation

🔴 The Problem: Inspectors currently use a two-step process—recording data in hard copy, then re-entering it into various software like Word, Excel, and AutoCAD, manually compiling a final report in PDF.

✅ The Solution: The API Collector App eliminates duplicate data entry, cutting time spent on documentation in half.

2. The Inefficiency of Using Multiple Software Programs

🔴 The Problem: Without a unified system, inspectors must navigate multiple tools:

- Code books for specifications

- MS Word for reports

- Excel for calculations

- Drawing tools (AutoCAD, Paint) for sketches

- Adobe to compile and format PDFs

✅ The Solution: APITB integrates all these functions into one seamless platform, reducing errors and eliminating the need for tedious manual compilation.

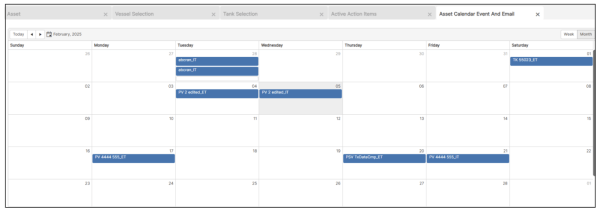

Calendar view showing all upcoming inspections in API Toolbox

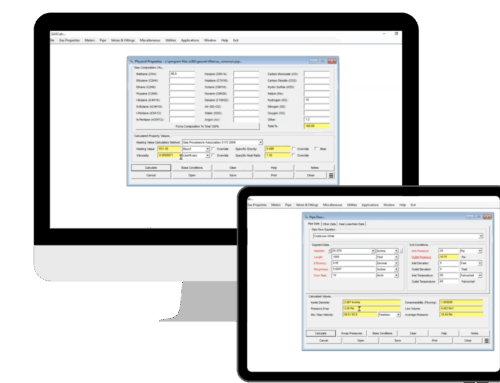

3. The Limitations of Excel-Based Reporting

🔴 Common Issues with Excel Spreadsheets:

- Complex File Management—Lack of organization, multiple file versions

- Repetitive Data Entry—Time-consuming and error-prone

- Data Integrity Risks—Inconsistent formats and misplaced calculations

- Frustration & Time Drain—Reports take days to compile manually

✅ The Solution: APITB automates calculations, centralizes data, and ensures accuracy—improving efficiency by 50% to 70% compared to Excel-based reporting.

4. Challenges with Referencing Standards & Code Compliance

🔴 The Problem: Inspectors spend excessive time manually searching for material specs, year-specific code requirements, stress values, and safety data sheets (SDS). The process is inefficient, fragmented, and increases the risk of misdiagnosis.

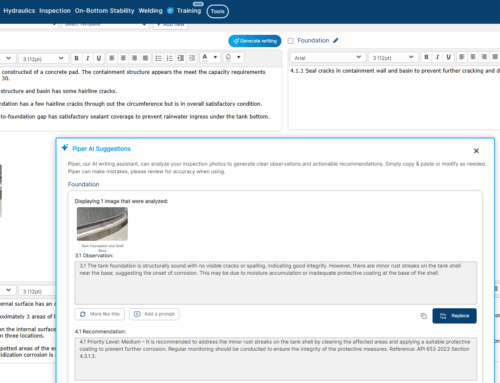

✅ The Solution: APITB integrates automated code lookups and a searchable reference library, ensuring faster, error-free compliance checks.

5. The Pitfalls of Excel-Based Asset Tracking

🔴 The Problem: Without a structured asset tracking system, inspection intervals and maintenance history are difficult to manage. When key personnel leave a company, they often leave behind disorganized spreadsheets, creating confusion and potential compliance risks.

✅ The Solution: The APITB Asset Management Database keeps all asset information centralized, up to date, and easily accessible, ensuring smooth transitions and accurate inspection scheduling.

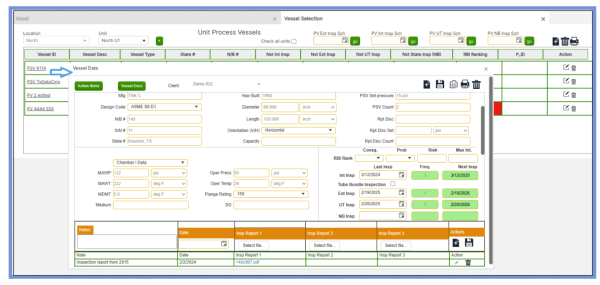

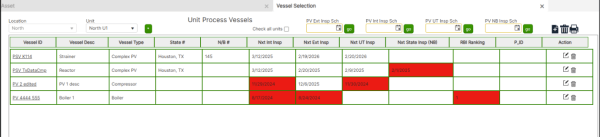

Showing all vessels added and all Inspection Dates. Red is past due dates.

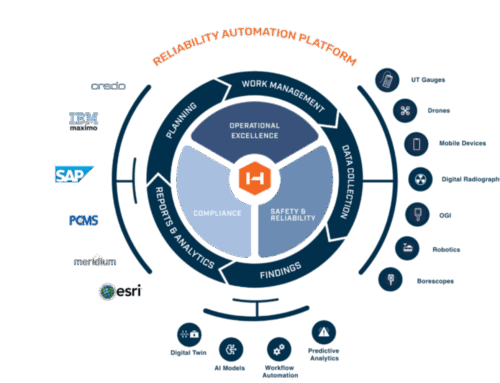

6. Why SAP & Maximo Fall Short for Inspections

🔴 The Problem: While SAP and Maximo are powerful for maintenance tracking, they lack:

- A centralized hub for storing supporting documents (CAD drawings, equipment specs, previous reports)

- A structured workflow for inspection tracking and compliance documentation

✅ The Solution: APITB acts as a comprehensive asset management tool, connecting reports, action items, inspection intervals, and risk assessments in a user-friendly database.

7. The Complexity of Other Asset Tracking Software

🔴 The Problem: Many existing solutions, like U-Pipe, Meridian, and PCMS, are overly complex, expensive, and require excessive approvals, delaying critical responses.

✅ The Solution: APITB is designed with simplicity and efficiency in mind, reducing approval bottlenecks while maintaining compliance, safety, and accountability.

The Bottom Line: Stronger Compliance, Faster Reporting, and Reduced Risk

APITB is the ultimate solution for inspection companies and asset owners.

- Ensures safety & compliance by reducing human error and report backlog

- Cuts reporting time by 50-70%, optimizing both fieldwork and documentation

- Integrates data seamlessly, eliminating redundant manual processes

By streamlining inspections and reporting, APITB empowers companies to stay ahead of compliance requirements, enhance operational efficiency, and mitigate costly risks. Want to see how your team can move from bottlenecks to audit-ready compliance? Get the API AMDB overview.

Watch Full API Toolbox AMDB Demo

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]