HDD Geotechnical Considerations

By David Willoughby

Crucial Role of Soil Identification in HDD Design and Construction

Soil identification is the foundation for HDD design and construction. Soil and groundwater react with many aspects of the drilling process and the soil properties significantly influence HDD construction. Understanding the soil conditions of the site will provide guidance on a specific drill path.

The HDD industry has accepted the need and benefit of a thorough geotechnical investigation to support the design and construction of HDD crossings. The purpose of the geotechnical investigation is to determine if directional drilling is feasible and to determine the most efficient way to accomplish it. The technical feasibility of an HDD project significantly depends on the subsurface conditions that the bore path must penetrate.

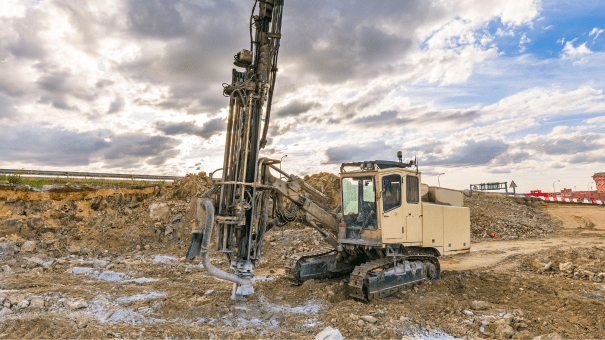

Geotechnical Investigations Through Drilling Test Holes in HDD

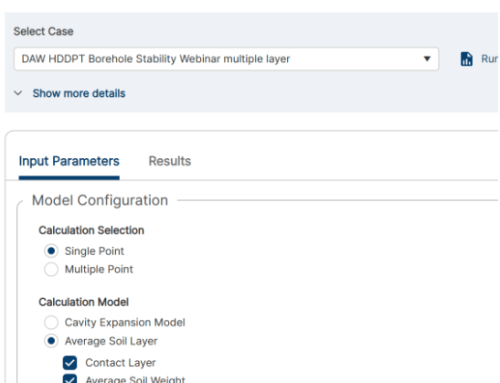

Drilling test holes is the most common method for performing geotechnical investigations. The test hole logs should include a complete description of the materials encountered, typically defined in accordance with the Unified Soil Classification System for soils. Test holes should be located to provide the most useful information about the project area. Evenly spaced test holes are often used, however, do not overlook areas that require special attention. Typically test holes are bored at a minimum of 30-60 feet below the designed drill path.

For drill paths shorter than 1,000-feet, two soil test borings (one on each end of the bore) may be adequate. If the data from these test borings indicate that the conditions are likely to be homogeneous on both sides of the boring, it may not be necessary to conduct any more test borings. For drill paths longer than 1,000-feet, soil test borings are typically taken at 500 to 700 ft intervals. When test holes are required, it is important that they are conducted by qualified personnel and that the needed data is obtained from the test hole investigation.

Navigating HDD Design Challenges

Regardless of the level of geotechnical work, it is important that HDD designers understand geotechnical reports, be able to analyze the subsurface data, and be knowledgeable about how the subsurface data impacts HDD design and construction. When evaluating the geotechnical data, the designer needs to identify the conditions that make HDD impractical and the conditions that just make HDD challenging.

Key Soil Considerations

From a geotechnical perspective, several key issues need to be considered and evaluated during HDD feasibility analysis and during HDD design and construction:

- The distribution and characteristics of the soil deposits.

- The presence of high plastic clay and bentonite-based shale bedrock materials; and

- The presence of complex, hard, and/or abrasive bedrock formations.

Particle Properties and Unified Soil

The soil performance in HDD depends on many factors such as soil grain particle properties and soil grain particle size distribution. Soil properties impact the HDD methods utilized and what may seem simple is a complex interaction between soil and various components of the drilling process. Since successful HDD projects largely depend on the ability to create and maintain a stable borehole while efficiently suspending and removing soil cuttings, the in-situ and disturbed soil characteristics are important for HDD projects. Properly interpreting the subsurface data provided on boring logs and in geotechnical reports is an important part of the HDD process. The Unified Soil Classification System (USCS) is typically used for HDD. This system classifies soils into two main groups:

- Coarse-grained soils (granular); sands, gravels, and larger particles

- Fine-grained soils (cohesive); silts, clays

Grain Size and Plasticity

The basis is that the engineering behavior of coarse-grained soils is related to their grain size distributions and the engineering behavior of fine-grained soils is related to their plasticity characteristics. Granular soils may have rounded or angular particles. Round soil grain particles have less interlocking ability than angular particles and provide lower stability for a drill hole than for angular particles.

Strength, Properties, and Considerations

Cohesive soil includes clay (fine grained soil), or soil with a high clay content, which has cohesive strength. Cohesive soils include clayey silt, sandy clay, silty clay, clay, and organic clay. Cohesive soil does not crumble, can be excavated with vertical side slopes, and is plastic when moist. Cohesive soils such as clays, silty clays, and silty clayey tills will usually support the open hole condition for HDD. Influential properties for cohesive soils with respect to drilling include the plastic properties of the specific clay, the particle size distribution, and the natural moisture content.

More on HDD

For more information regarding this blog topic, read our Soil Type Impact in HDD blog or join me in my training on Advanced HDD for Pipelines. You can also contact me, the author, David Willoughby, at [email protected]

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]