Horizontal Directional Drilling (HDD): Designing for Success

By David Willoughby

Minimize Risk and Optimize Design in HDD Crossings

HDD projects can be a major event, such as a significant water crossing, or a relatively minor project, such as crossing driveways or roads. Regardless of the nature of the HDD project, potential risks and problems should be identified early in the planning and design process. Many projects require extensive surface and subsurface investigations by qualified engineers to determine the feasibility of the HDD project and to assist the owner in the preparation, planning, and design of the project. The level of design engineering effort for an HDD project is affected by many factors such as site conditions, soil formations, terrain, existing utilities, and equipment set-up restraints. Regardless of the up-front engineering effort, it is not unusual for the final bore path to change from the original design because of the actual drilling conditions encountered. A key factor in a successful HDD design and crossing is understanding how various factors impact the potential for a successful crossing.

In many instances, the feasibility considerations can be answered quickly by someone experienced with HDD applications. Based on their knowledge of the project area, HDD equipment, HDD technology, HDD practices, and HDD contracts, the likelihood of project success can be estimated. However, in many cases, the answers to the feasibility questions require extensive work and research to accurately assess the technical and economic aspects of the project. In these instances, detailed planning, research, and coordination are required to identify the possible problems or challenges for an HDD project.

HDD Site Surveys and Risk Assessment

There are many factors to consider when evaluating the likelihood of success of an HDD project. Conducting a site survey, usually the first step, is important for all HDD projects and is a significant part of the HDD site characterization. The site survey should include surface and subsurface investigations. Successful trenchless projects are usually based on a design that is specifically tailored to the site and the anticipated subsurface conditions. Experience has taught us that a thorough site and subsurface investigation by qualified personnel prior to project design and construction is the most effective means of managing project risks. The purpose of the site characterization is to identify and avoid potential problems, assess the risk associated with the site conditions, and ensure the project is properly designed. The main goals of the site characterization are typically:

- Topographic survey of the pipe alignment.

- Identifying and locating features in the vicinity of the drill path.

- Identifying the surface and subsurface conditions.

- Determine geology of soil between the drill path and surface.

- Develop a detailed analysis of the surface and subsurface conditions.

- Analyze the effectiveness of HDD methods in the anticipated subsurface conditions.

Surface Conditions and Topography Impact HDD Success

For the surface characterization, the primary consideration is the project area’s suitability for the layout of the required HDD equipment and the product pipe. The surface impact associated with construction of a pipeline crossing by HDD is significantly less than the impact associated with construction by open cut excavation. However, the HDD construction is not without some surface impact. When the work areas are limited, before declaring that an HDD project is not technically feasible, alternate scenarios for performing the HDD should be considered. Identify surface features such as buildings, roads, utility features, etc. Pay close attention to low areas where the overburden thickness of the soil/rock over the HDD drill path may be the lowest. It is also necessary to check available utility records to help identify the location of existing below-ground facilities in the vicinity, including electric power, natural gas, petroleum, water, sewer, or telecommunications lines.

The presence of existing pipelines, support pilings, etc., containing significant steel mass should be noted since this may cause interference with magnetically sensitive equipment guidance or location instrumentation. One key factor of topographic relief occurs when the surface pipe entry and exit elevations are substantially different. If there is a significant elevation difference between the entry and exit points, the drilling fluid elevation in the hole will tend to equalize to the lower of the two points once the pilot hole is completed. Because a portion of the hole is then situated above the drilling fluid equilibrium elevation, this creates a “dry” section within the hole, which can increase the risk of instability and other problems during construction operations.

In soil formations, this instability can contribute to the collapse of the hole, eventually leading to ground-surface settlement and the potential formation of sinkholes along the HDD alignment. Tooling may also become stuck downhole, and the product pipe may get damaged or stuck during installation.

How Subsurface Conditions Impact HDD Feasibility and Design

After determining if the surface conditions are suitable for HDD construction, the next item to consider is the subsurface conditions. A vital element of many HDD design projects is a geotechnical survey to identify soil formations at the potential HDD site. Soil and groundwater react with many aspects of the drilling process. Soil properties will significantly influence HDD construction, and an understanding of the site will provide guidance as to where and what the impacts will be on a specific drill path.

The HDD industry has accepted the need and benefit of a thorough geotechnical investigation. The purpose of the geotechnical investigation is to determine if directional drilling is feasible and to determine the most efficient way to accomplish it. This information is used to develop design drawings (including final bore route, pipe design, and bore design), construction specifications, and permit applications. The contractors also use this information to help them select the appropriate tools and methods for the actual construction.

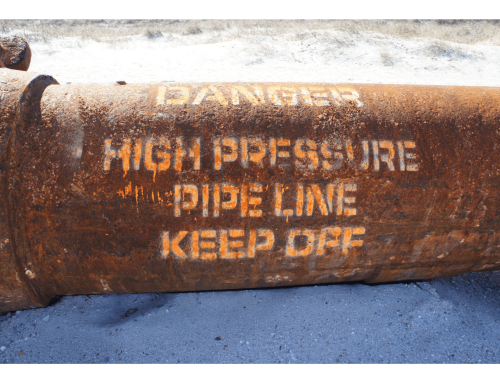

Avoiding Hydrofracture and Environmental Risks in HDD Crossings

A successful HDD crossing includes more than just pulling the pipeline through a borehole. A successful HDD crossing includes taking proper measures to avoid damage to the environment or infrastructure. An important part of avoiding damage is to ensure the HDD is at the required depth. Using standard rules of thumb for minimum depth of cover for HDD construction is an outdated practice and should no longer be used. The depth of cover should be governed by the definition of the obstacle. Depth of cover requirements are dependent upon several factors such as subsurface conditions, type of drilling equipment, mud pressure, and the difference in elevation between the entry and exit points. The minimum depth of cover should be established by the calculations for maximum borehole pressures and a comparison of those pressures and reasonable drilling pressures. In the case where the reasonable operational drilling pressure exceeds the maximum drilling pressure, the HDD profile should be set deeper to raise the maximum drilling pressure. Use the maximum and minimum calculated pressures to check the chance of hydro fracture in areas of interest, such as low earth cover, utility crossings, water crossings, highway crossings, environmentally sensitive areas, and at large distances from the entry point.

A successful HDD isn’t just about the geometry of the crossing or the calls, it’s about constructability. To provide the HDD contractor with the best chance for success, a good HDD design, based on risk factors and feasibility, is important

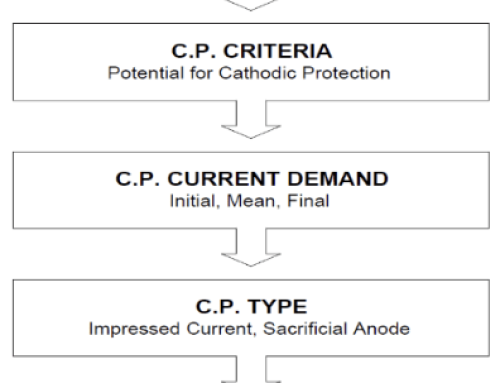

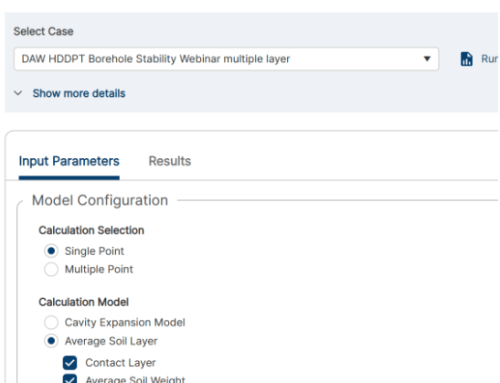

Before finalizing your HDD design, use a structured checklist to ensure soil data, borehole stability, and alignment risks are covered. The new HDD Stability Checklist provides a step-by-step framework for safer, more predictable designs

More on HDD

For more information regarding this blog topic, read our Soil Type Impact in HDD blog or join me in my self-paced training on Advanced HDD for Pipelines. You can also contact me, the author, David Willoughby, at [email protected]

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]