How Soil Type Impacts HDD Design/Construction

Part 1

By David Willoughby

Successful HDD (Horizontal Directional Drilling)

Factors that make a successful HDD are interrelated. The factors that contribute to HDD success are soil identification, drilling fluid selection, bit and reamer selection, and adequate fluid volumes. When evaluating the geotechnical data, the designer needs to identify the conditions that make HDD impractical and the conditions that just make HDD challenging.

From a geotechnical perspective, several key issues need to be considered and evaluated during HDD feasibility:

- Distribution and characteristics of the soil deposits

- The presence of high plastic clay and bentonite-based shale bedrock materials

- The presence of complex, hard, and/or abrasive bedrock formations

Effective HDD design requires an understanding of soil composition. Soil is primarily rock that has weathered and produced a broad range of particle sizes and chemical compositions. The concentration of particles allows the identification of the soil types by their characteristic properties. Soil properties impact the HDD methods utilized, and what may seem simple is a complex interaction between soil and various components of the drilling process. Since successful HDD projects largely depend on the ability to create and maintain a stable borehole while efficiently suspending and removing soil cuttings, the in-situ and disturbed soil characteristics are important for HDD projects. Properly interpreting the subsurface data provided on boring logs and in geotechnical reports is an important part of the HDD process.

Soil Classification

The Unified Soil Classification System (USCS) classifies soils into two main groups:

- Coarse-grained soils (granular); sands, gravels, and larger particles.

- Fine-grained soils (cohesive); silts and clays.

We will cover granular soils in this blog and cohesive soils in the next blog.

Coarse-Grained Soils

The engineering behavior of coarse-grained soils is related to grain size and grain distribution. The shape of the soil grain influences the packing arrangement of a granular formation and the stability of the packing. Granular soils may have rounded or angular particles. The round particles are caused by a tumbling process, such as in a river, and angular particles result from geologic processes that fracture material, such as glacial crushing or weathering of intact rock.

Impact of Grain Shape on Drilling:

- Round particles: Have less interlocking ability than angular particles and provide lower stability for a drill hole than for angular particles.

- Angular particles: Have a greater interlocking capability. Angular soil grain particles have a better ability to remain stable in a drill hole configuration.

The soil grain size can impact steering, the force required to penetrate the formation, and drilling fluid properties.

Soil grain particles that are larger than approximately 1/3 of the bit or reamer diameter may cause the drill to be deflected away from the particle. Materials larger than 3 inches in diameter, such as cobbles and boulders, make HDD a very high-risk method. These sizes of materials are almost impossible to remove from the borehole. If significant quantities of cobbles or boulders are identified during the geotechnical investigation, the best option is to try and avoid them. Soils that have 50% or more gravel size material are very questionable for HDD construction.

A common view in the HDD industry is that soil material ¾ inches or larger (coarse gravel) cannot be suspended in an efficient drilling fluid. Drilling fluid that is prepared to handle large coarse material typically ends up being too viscous to be useable in the HDD system. Drilling in significant layers of coarse material is not typically feasible unless the following conditions exist: The coarse material is smaller than ¾ inches. The soil contains adequate fines (smaller than 0.003 inches; # 200 sieve) to provide borehole stability and prevent fluid loss into the formation.

Conclusion

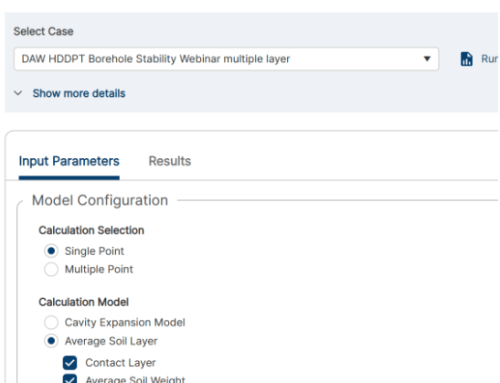

For more information regarding this blog topic, please join us in either of the following two webinars: “Horizontal Directional Drilling for Pipelines Design Example and Stress Analysis Workshop”, or “HDD for Pipelines Design Example and Stress Analysis Workshop”

Or contact the author, David Willoughby, at [email protected]