How Soil Type Impacts HDD Design/Construction

Part 2

By David Willoughby

Introduction

In the last blog, “How Soil Type Impacts HDD Design/Construction Part 1” we covered granular soils. In this blog, we will cover fine-grained soils (cohesive); silts, and clays. The engineering behavior of fine-grained soils is related to plasticity characteristics. Silt and clay size soils (50% pass #200 sieve, smaller than 0.003 inches) are classified by plasticity. The plastic properties are defined by a soil’s Atterberg Limits, which are related to the moisture contents between which the soil exhibits plastic behavior.

The moisture content is determined by a laboratory test resulting in a:

- Plastic Limit– Cohesive soils begin to deform plastically when the moisture content exceeds what is called the Plastic Limit.

- Liquid Limit – The soil will continue to become more plastic as the moisture content increases up to the Liquid Limit above which the soil behaves as a liquid.

- Plastic Index- Soil above the liquid limit exhibits liquid behavior. The soil below the plastic limit exhibits semi-solid or solid behavior.

Low to Medium Plasticity

Clays and soft shale formations of low to medium plasticity (liquid limit less than 50) have a low potential to swell and usually work well for HDD design and costruction. High plasticity clays (liquid limit greater than 50) and shale have the potential to swell and may restrict the borehole and increase the chance of hydrofracture without the proper additives and drilling procedures. The natural water content provides an important indication of the clay’s behavior when disturbed: solid, plastic, or liquid. The natural water content can be compared to the Atterberg Limit moisture content to assess which of the behaviors would be expected of the clay. A solid condition would have a natural moisture content below the Plastic limit. This condition will likely want to absorb water from the drill fluid and dry the drill fluid with time. The speed and severity of this process depend on the type of clay being drilled.

A plastic condition would be expected if the natural water content was between the plastic and liquid limits. This condition is generally the most stable for drilling though it will have a higher tendency to mix with the drill fluid resulting in a thickening of the drill fluid. A liquid condition would be expected if the natural water content was above the liquid limit. This condition is unstable during drilling, and the hole should be expected to close during the drilling process and relatively quickly after drilling has stopped.

Factors Affecting Swelling

A fine-grained soil’s tendency to swell is affected by water content, plasticity, density, and formation (overburden) pressure.

Dry Soils

- Dry soils are more likely to swell, and saturated soils or soils below the water table do not swell.

- High-plastic soils (fat clay or elastic silt) are more likely to swell than low to medium-plastic soils (lean clay or silt).

- Soils with a higher dry density are more likely to swell than lower-density soils.

- Soils under relatively high formation pressure tend to swell due to stress relief around the borehole when the formation is cut.

Swelling can often be prevented by the use of polymers and adequate drilling fluid volume.

Conclusion

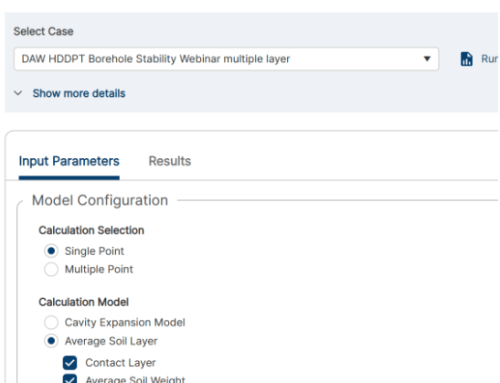

For more information regarding this blog topic, read the previous blog on “How Soil Type Impacts HDD Design/Construction Part 1” or join us in either of the following two webinars on: “Horizontal Directional Drilling for Pipelines Design Example and Stress Analysis Workshop”, or “HDD for Pipelines Design Example and Stress Analysis Workshop”

Or contact the author, David Willoughby, at [email protected]