Step-by-Step Guide to Conducting a Pipeline Pressure Test

By Febin Jose

Ensuring the integrity of pipelines is crucial to maintaining safety and compliance in the oil and gas industry. One of the most effective methods to verify a pipeline’s strength and leak resistance is through pressure testing, often referred to as hydrostatic testing or hydrotesting. This guide walks you through the hydrotest procedure, from preparation to analysis, focusing on safety and efficiency.

What is Pipeline Pressure Testing?

Pipeline pressure testing involves filling a pipeline with a liquid or gas, pressurizing it above its normal operating level, and monitoring for leaks or structural weaknesses. This process ensures compliance with regulatory standards and verifies the Maximum Allowable Operating Pressure (MAOP) of the pipeline.

Pipeline Test Preparation

Proper preparation is the foundation of a successful hydrotest. Here’s what you need to do:

- Review Pipeline Specifications: Identify MAOP, wall thickness, and material properties. Use software like the Hydrotest PowerTool to gather and validate critical data

- Segment Selection: Divide the pipeline into manageable sections, considering elevation changes, valve locations, and test head placement. Intelligent sectioning tools can automate this step for efficiency.

- Water Sourcing and Disposal: Plan for the sourcing, transportation, and safe disposal of test water. Consider local environmental regulations

- Equipment Setup: Prepare test heads, pressure gauges, and monitoring equipment. Ensure all tools meet industry standards

Hydrotest Procedure

- Filling the Pipeline

- Fill the pipeline with water (or another test medium) using pumps designed for high-pressure operations

- Remove air pockets, which can affect pressure stability, by installing air-release valves at high points

- Pressurization

- Gradually increase pressure to the predetermined test level, typically 1.25 times the pipeline’s MAOP

- Maintain the pressure for a specified duration, usually 8 hours or more, depending on regulatory requirements

- Monitoring

- Continuously monitor pressure levels and temperature changes

- Record data using automated systems integrated with tools like the Pipeline HUB for accuracy and real-time analysis

Safety in Pressure Testing

Safety is paramount during a hydrotest. Follow these best practices:

- Personnel Training: Ensure all team members understand hydrotest procedures and emergency protocols

- Safety Barriers: Install barriers around high-pressure zones to prevent accidents

- Equipment Checks: Inspect all testing equipment before use to eliminate risks of malfunction

Analyzing Pressure Test Results

After the test, analyze the recorded data to assess pipeline integrity:

- Leak Detection: Identify pressure drops that may indicate leaks. Use thermal imaging or acoustic sensors to pinpoint leak locations

- Structural Assessment: Evaluate whether the pipeline withstood the test pressure without deformation

- Compliance Reporting: Document the results in a traceable, verifiable, and complete (TVC) format, as required by industry standards

Why Use Advanced Hydrotest Tools?

Modern tools like the Hydrotest PowerTool streamline the testing process by automating data collection, sectioning, and result analysis. These tools integrate with platforms like the Pipeline HUB, ensuring accurate recordkeeping and compliance with regulatory standards.

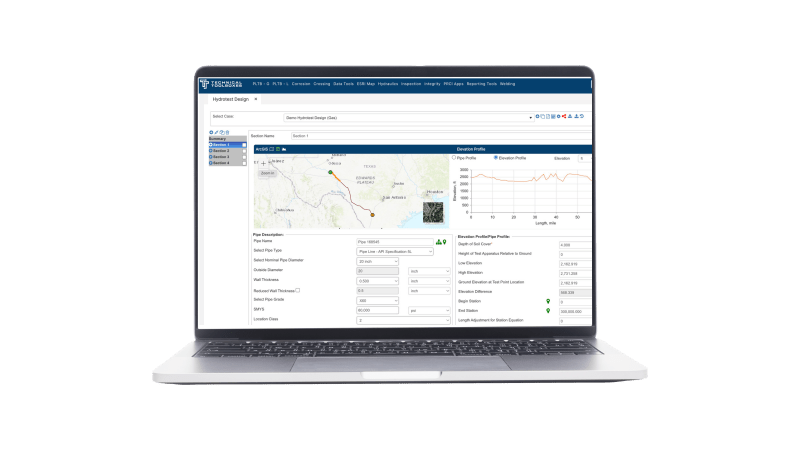

Hydrotest PowerTool from Technical Toolboxes

Conclusion

Conducting a pipeline pressure test is a critical step in pipeline integrity management. By following this guide and leveraging advanced tools, you can ensure accurate, safe, and compliant testing. From preparation to result analysis, every step is essential to protecting both assets and the environment.

Have questions about hydrotesting? Contact us to learn how advanced solutions can optimize your testing process.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]