The Intricacies of Borehole Stability in Horizontal Directional Drilling

By Febin Jose, Technical Toolboxes

In our recent webinar, we focused intensively on the complexities of maintaining borehole stability during Horizontal Directional Drilling (HDD). This vital aspect of HDD ensures the safety and success of drilling operations, particularly in challenging geological settings. This blog aims to shed light on the scientific and technical underpinnings of borehole stability, providing a deeper understanding for engineering professionals and students alike.

Defining Borehole Stability

Borehole stability refers to the ability of a drilled hole to maintain its structural integrity throughout the drilling process and afterward. It is crucial for preventing non-productive time (NPT) due to issues like borehole collapse, stuck pipe incidents, and lost circulation.

Factors Influencing Borehole Stability

- Geological Conditions: The type of rock or soil, its strength, and the presence of faults or fractures play a critical role in determining how stable the borehole will be. Variations in these conditions can significantly impact the required drilling techniques and precautions.

- Pore Pressure and Fracture Gradients: Accurate prediction and management of downhole pressures are essential to maintain borehole stability. Understanding the balance between pore pressure and the fracture gradient helps in selecting appropriate mud weights that prevent collapse and fracturing.

- Drilling Fluid Properties: The type of drilling fluid and its properties, such as density, viscosity, and thixotropy, are selected based on their ability to stabilize the borehole. Drilling fluids must be engineered to counteract the geological stresses encountered during drilling.

- Stress Regime: The in-situ stress orientation and magnitude influence how the borehole might deform. Effective stress management strategies, like adjusting the drilling direction to align with or against the principal stress directions, can enhance stability.

Analytical and Empirical Methods for Stability Analysis

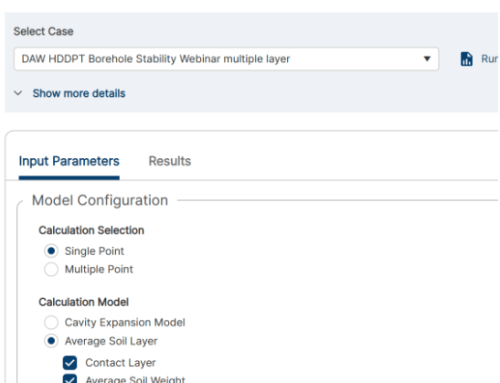

In our webinar, we explored various analytical and empirical methods to assess borehole stability:

- Analytical Models: These involve calculations based on the mechanical properties of the rock and the stresses applied during drilling. During the webinar, we discussed several specific models that are instrumental in predicting borehole stability, including the Delft model, the Average Delft model, and the Queens model. These models provide a framework for understanding the interaction between the borehole wall and the surrounding geological formations, allowing engineers to predict zones of potential instability before drilling commences. Each model offers unique insights into the behavior of different rock types under stress, making them invaluable tools for pre-drilling assessments.

- Empirical Data and Case Histories: Learning from previous drilling experiences in similar conditions allows for a more informed approach to managing borehole stability. It includes adapting drilling parameters based on historical data to mitigate potential issues.

- Real-Time Monitoring: Modern drilling operations incorporate real-time monitoring of parameters like torque, drag, and fluid loss, which serve as indicators of borehole conditions. This data allows for immediate adjustments to drilling operations to enhance stability.

Educational Value of Borehole Stability

Understanding borehole stability is not only crucial for field engineers but also forms a core part of the curriculum for petroleum and geological engineering students. Detailed knowledge of the factors affecting borehole integrity prepares budding engineers for the challenges of HDD projects and enhances their problem-solving skills in real-world scenarios.

Conclusion

The maintenance of borehole stability is a complex but critical component of successful HDD operations. It requires a multidisciplinary approach that encompasses geology, fluid mechanics, and structural engineering. For those looking to delve deeper into this subject or to integrate advanced borehole stability analysis into their projects, our resources and detailed studies on the subject are available. Continued education and practical application of these principles are essential for advancing the safety and efficiency of future drilling operations.

Better your HDD design validations and analysis by learning more about our HDD PowerTool.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]