The Science of Pipeline Blasting: Techniques and Safety Measures

By Kesley Price

Pipeline blasting is a critical operation in the construction and maintenance of pipeline systems. It involves the use of controlled explosives to clear rock or soil and create space for pipeline installation. Given the complexity and potential risks, this process demands meticulous planning and adherence to stringent safety standards. This blog explores the techniques, safety measures, and environmental considerations that underpin effective and safe pipeline blasting.

Techniques in Pipeline Blasting

- Controlled Blasting

Controlled blasting minimizes the impact of explosive energy to prevent damage to existing structures and pipelines. Techniques include:- Pre-Splitting: Creating a barrier to control the direction of the blast and limit the zone of fracture.

- Buffer Blasting: Using smaller charges to reduce vibrations near sensitive structures.

- Trench Blasting: Carefully aligning charges in a trench to create a precise pipeline path.

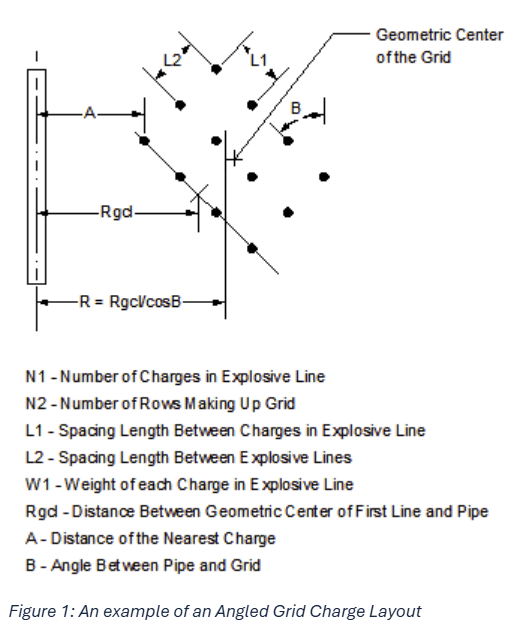

- Blasting Calculations

Precise calculations are essential for successful blasting. Tools like the Pipeline Toolbox (PLTB) provide algorithms to assess tensile stress-strain, surface loading, and vibrations. These calculations ensure that the blast effects are within regulatory compliance and optimized for safety. - Environmental Considerations

Blasting near sensitive areas such as wetlands or populated regions requires:- Monitoring Vibration and Sound Levels: Using seismographs to record ground vibrations and air overpressure.

- Controlled Use of Explosives: Reducing the charge weight per delay to limit environmental disturbance.

Safety Measures in Pipeline Blasting

- Risk Assessments and Pre-Blast Surveys

Before any blast, engineers conduct thorough site assessments to identify potential hazards. Pre-blast surveys document existing structures and environmental conditions to mitigate risks. - Blasting Safety Protocols

- Personnel Safety: Setting up exclusion zones to keep personnel safe during blasting operations.

- Protective Equipment: Ensuring workers use personal protective equipment (PPE) like helmets, goggles, and hearing protection.

- Emergency Procedures: Having clear evacuation and response plans in place.

- Regulatory Compliance

Adhering to local and federal regulations, such as those outlined by PHMSA and ASME, ensures safety and legal compliance during pipeline blasting operations.

Optimizing Blasting Techniques

- Simulation Tools

Advanced software like the Pipeline Toolbox (PLTB) enables engineers to simulate blasting scenarios, reducing trial and error and enhancing precision. - Data Integration and GIS Mapping

By leveraging GIS mapping tools, engineers can visualize blast sites in detail, improving the accuracy of the operation and minimizing unforeseen issues. - Continuous Monitoring

Post-blasting monitoring ensures that the effects are as planned and helps identify any structural concerns immediately.

Environmental Considerations

Environmental stewardship is a priority in pipeline blasting. Mitigation strategies include:

- Dust and Debris Management: Using water sprays to reduce airborne particulates.

- Minimizing Soil Displacement: Employing techniques to stabilize the soil and prevent erosion.

- Noise Reduction Measures: Using sound barriers where necessary.

Pipeline blasting, when executed with precision and adherence to safety standards, is a highly effective method for facilitating pipeline installation. Leveraging advanced tools like PLTB not only enhances safety but also optimizes the blasting process, ensuring environmental and operational integrity. Understanding and applying these principles is essential for success in pipeline projects.

For further insights into specialized tools for pipeline engineering, explore the Pipeline Toolbox and related solutions.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]