Introducing CEPA Surface Load Calculations for Pipeline Toolbox!

CEPA Principle Methods

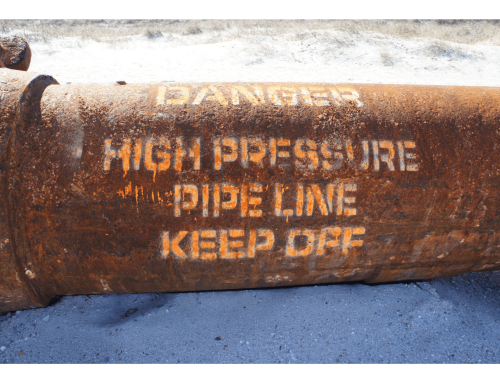

Buried pipelines take a lot of stress over time from vehicles, encroachment, and changes to soil conditions. Therefore it’s critical to calculate the overburden stress and loads on pipes to ensure an accident does not occur over time.

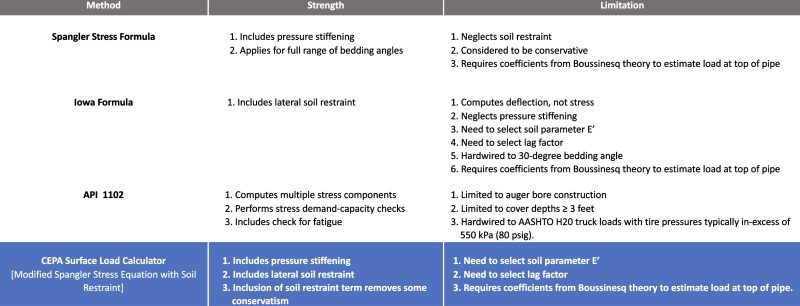

There are a variety of Principle Methods for calculating vertical loading effects on buried pipelines, the most famous being API 1102, but also the Spangler Stress Formula, the Iowa Formula, and most recently, the CEPA Surface Load Calculator.

API 1102 May Not Give the Complete Picture

API 1102 is a widely used standard, but comes with its limitations, mainly that it is limited to cover depths greater than or equal to 3 feet and has been specifically developed based on AASHTO H20 truck loads with small footprints associated with tire pressures typically in-excess of 550 kPa (80 psig). Several important limitations are inherent to this method, which creates limitations to complete adoption:

- It cannot be effectively extrapolated to shallow cover situations

- It may not scale correctly to different types of equipment that ride on floatation tires or caterpillar tracks where ground surface pressures are less than 350 kPa (50 psig)

- It determines pipeline stresses in a non-traditional manner

CEPA Surface Load Calculations Takes a Different Approach

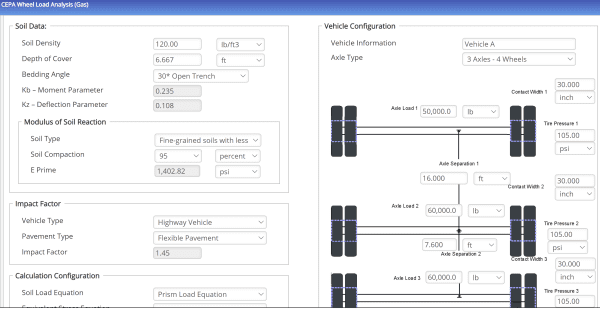

The CEPA Surface Load Calculator approach is slightly different: it’s simpler and considered less conservative. It allows pipeline operators and service providers to understand if a pipe requires added protection, or if a more detailed calculation is appropriate. The goal of the assessment method is to use relatively simple and easily obtainable attributes (e.g., wheel or axle load, ground surface contact area and/or surface loading pressure, depth of cover, maximum allowable operating pressure and design factor) to quickly understand if additional analysis is needed, or if the pipe is safe to cross.

The CEPA Surface Load Calculator approach is slightly different: it’s simpler and considered less conservative. It allows pipeline operators and service providers to understand if a pipe requires added protection, or if a more detailed calculation is appropriate. The goal of the assessment method is to use relatively simple and easily obtainable attributes (e.g., wheel or axle load, ground surface contact area and/or surface loading pressure, depth of cover, maximum allowable operating pressure and design factor) to quickly understand if additional analysis is needed, or if the pipe is safe to cross.

A Comparison of Principle Methods for Evaluating Vertical Loading Effects on Buried Pipeline

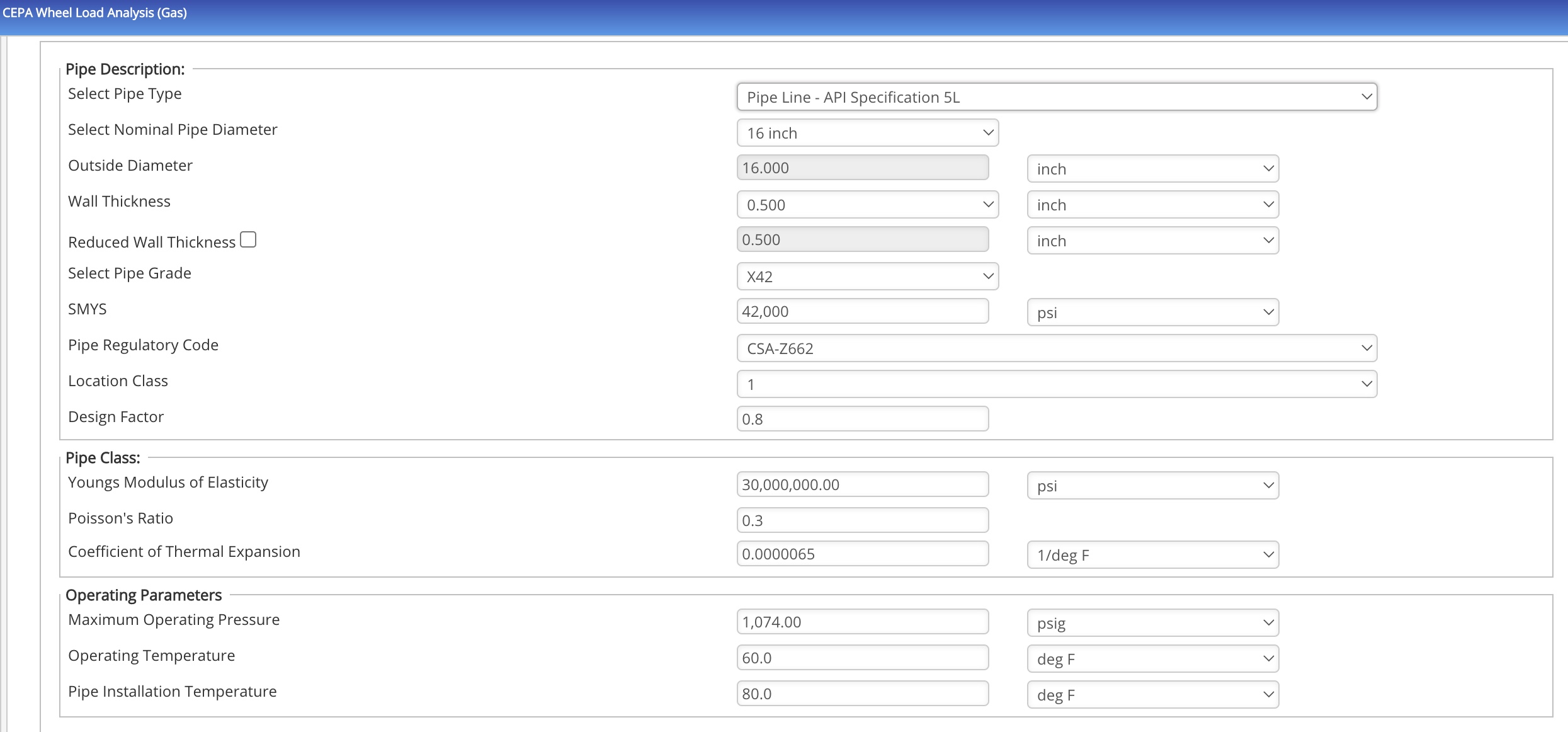

CEPA Crossings Calculations – Now Available in Pipeline Toolbox!

We’re happy to announce that we’ve added CEPA Wheel, Track, and Grid Load for liquid and gas to Pipeline Toolbox! This gives the additional flexibility of measurement using the CEPA methods, in addition to the other crossings methods already available, such as API 1102.

An example of CEPA Wheel Load Analysis in Pipeline Toolbox today

Which Standard is Right For You? The Right Answer Might be All of the Above!

As shown in the table above, each method for surface loading analyses has its strengths and limitations, so in many cases, there may not be a “one size fits all” standard for crossings analysis. The good news is, using our Pipeline Crossings Workflow, you run any simultaneous combination of CEPA, API 1102, Wheel Load, Track load, and Crossing Design calculations to get a complete picture of a crossings scenario before it occurs. And with the addition of the CEPA calculator, we can now support the

- ASME B31.8

- ASME B31.4

- CSA Z662

This reduces risk in analysis, and has been shown to speed up analysis time by 50-75% for pipeline operators.

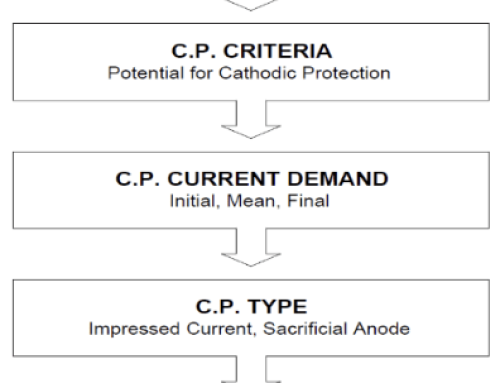

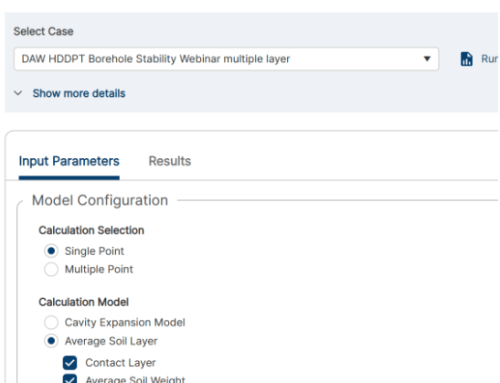

The Technical Toolboxes Crossings Suite Ties it All Together

Our Crossings Suite builds on the crossings calculations of Pipeline Toolbox alone. In the suite, engineers gain access to the entirety of the Pipeline Toolbox Enterprise along with several specialized engineering applications, such as the Crossings Workflow and Encroachment Manager. By integrating data, GIS, and reporting tools across the Crossings Suite and the entire software portfolio at large, pipeline engineers are empowered to work more productively, with less risk, and with a clearer understanding of their pipeline assets and calculations.