Why API Inspections Still Matter More Than Ever

By Kesley Price

In an industry where failure isn’t an option, your inspection data is only as good as your system for managing it.

API inspections, covering pressure vessels, pipelines, and storage tanks, are the backbone of mechanical integrity in oil and gas. Yet, many operators and service providers still rely on fragmented processes, legacy systems, or spreadsheets to manage this critical function.

What Are API Inspections, Really?

API inspections follow standards set by the American Petroleum Institute. These standards (such as API 510, 570, and 653) ensure the safe operation and compliance of:

- Pressure vessels (API 510)

- Piping systems (API 570)

- Aboveground storage tanks (API 653)

The purpose? To identify risks, evaluate remaining life, and recommend corrective actions, long before failure occurs.

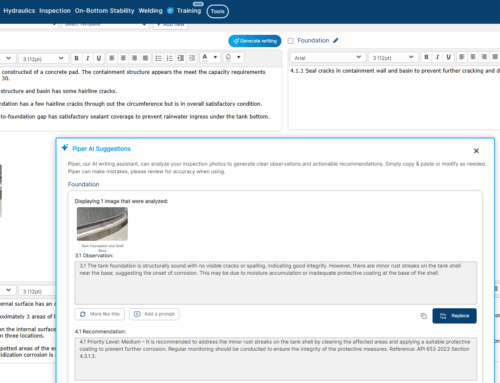

But the real challenge is consistency. Especially when inspectors are juggling site conditions, code references, calculations, and report generation, all while trying to stay compliant and audit ready.

The Rising Pressure of Compliance

Regulatory requirements are getting tougher. PHMSA and local regulations now mandate traceable, verifiable, and complete (TVC) documentation. That means your inspection records need to be airtight, from wall thickness readings to audit trails and failure analysis.

If you’re still relying on static PDFs or Excel sheets to manage inspection data, you’re exposing your operation to serious risk:

- Data errors

- Compliance gaps

- Audit failures

- Time-consuming rework

The Asset Management Piece Most Teams Overlook

While inspections are mission-critical, how you manage the data behind them is what determines your long-term integrity success.

Many inspection teams treat inspection data as one-and-done, stored in siloed reports, or buried in email chains. But in truth, this data should be dynamic, centralized, and reusable across multiple reports, tools, and audit cycles.

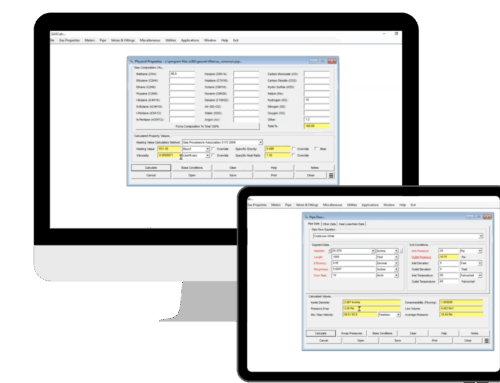

What’s missing for many teams is a reliable Asset Management Database (AMDB) designed specifically for API inspection workflows.

From Field to Report: The Inspection Lifecycle

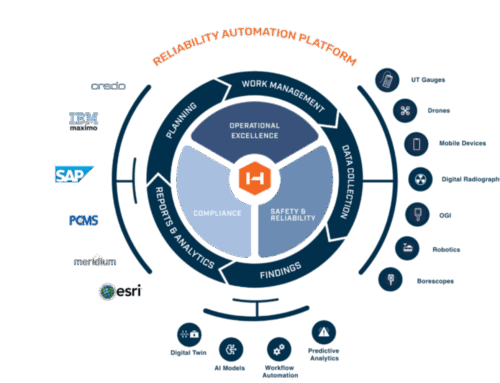

Here’s what best-in-class API inspection and asset management looks like:

- Collect field data using structured templates or mobile tools

- Centralize all asset information (tanks, vessels, piping) in one system

- Update records dynamically, so any changes cascade across reports

- Generate reports automatically using preloaded API standards

- Support audit readiness with TVC-compliant documentation.

This isn’t just about passing inspections; it’s about creating a process that protects your bottom line.

What Happens When You Get It Right?

- Fewer failed audits

- Faster reporting cycles

- More productive inspectors

- Extended asset life

- Less rework and double-entry

And most importantly, a system your entire team can trust.

Learn More

Want to simplify your API inspections and finally get your asset data under control?

Discover how the API Toolbox + Asset Management Database can help you move faster, stay compliant, and eliminate rework, without waiting months to implement a new system.

Let’s put your inspection data to work.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]