Corrosion Engineers: How Confident Are You in Your Remaining Strength Calculations?

By Kesley Price

You ran the corrosion calculation. But are you confident in the inputs? Did the spreadsheet flag the formula error? Can you prove that number holds up in an audit, or in court?

Most corrosion engineers rely on the RSTRENG method to calculate failure pressure. But even a small mistake, like estimating defect length instead of calculating it, can lead to major risk. Here’s why that matters more than ever.

Why These Calculations Matter

When external corrosion is discovered, pipeline engineers are tasked with determining whether a pipeline segment is still safe to operate. This often involves calculating failure pressure and deciding whether repair or replacement is needed. That process is more than just a box-checking exercise. It directly affects your:

- Operational risk profile

- Compliance with federal regulations

- Worker and public safety

- Downtime and cost of rework.

Most rely on RSTRENG method (or ASME B31G) to make these calls, but even the best methods can fall short when:

- Inputs are incomplete or incorrect

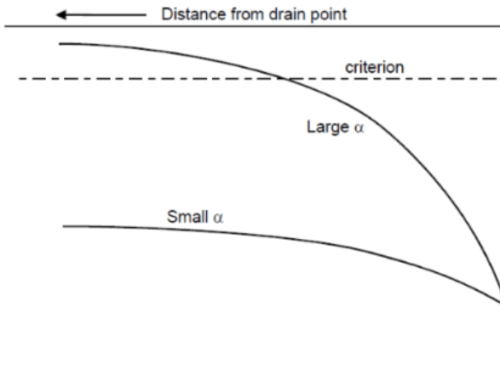

- The defect length is estimated instead of calculated

- Spreadsheets introduce unnoticed formula errors

- Results can’t be easily verified or shared across teams

- It’s not just a calculation, it’s a decision that could cost millions if it goes wrong.

The Hidden Cost of ‘Just Using a Spreadsheet’

Spreadsheets have their place, but pipeline integrity might not be one of them. Manual input, inconsistent formatting, and a lack of traceability can lead to issues in audits or incident investigations. Regulatory agencies like PHMSA expect TVC documentation: Traceable, Verifiable, and Complete. Can you confidently say your current process delivers that?

Is There a Smarter Way?

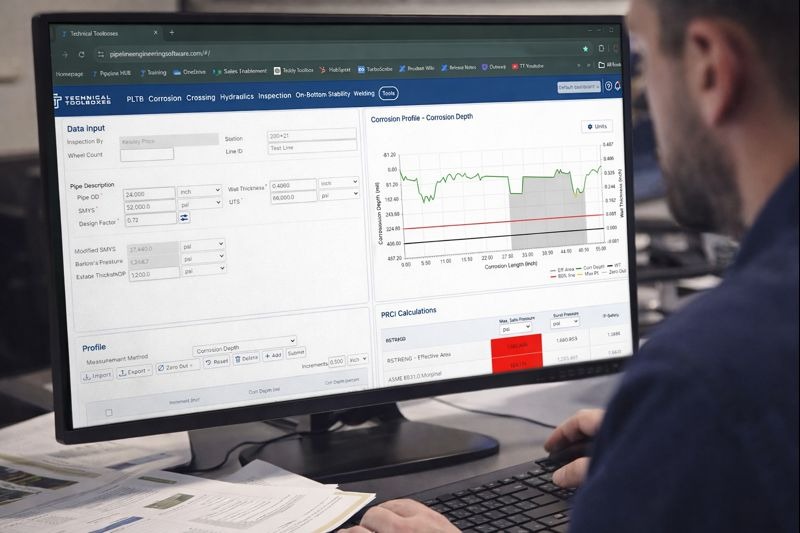

Many engineers don’t realize that tools exist that take the guesswork out of corrosion assessments. Imagine being able to automate defect length calculation using the Zero Out method, run multiple defect assessments at once (batch runs), compare scenarios to plan the best response, instantly simulate the impact of a repair patch, and maintain a complete audit trail of every input and result. That’s the kind of capability modern integrity engineers are moving toward – especially those working under tight deadlines or on high-risk segments.

When to Start Looking for a Better Tool

If you’re spending hours verifying hand calcs, concerned about audit readiness, constantly jumping between ILI reports, PDFs, and Excel sheets, tasked with assessing multiple corrosion sites at once, or tired of doing the same repetitive setup over and over – then you’re probably overdue for an upgraded system.

What’s Next?

You don’t need a full-blown enterprise software overhaul to improve your RSTRENG calculations. In fact, most modern tools can be adopted quickly and don’t require IT support. They integrate directly into your workflows and help your team move from reaction to prevention. Start by asking:

- What would more accurate corrosion assessments mean for your team?

- How much time could you get back by automating your remaining strength calcs?

- Could a missed calculation lead to a costly incident or shutdown?

Bottom line? If you’re still using spreadsheets to manage corrosion analysis, you’re doing more work than necessary and putting your PHMSA compliance and assets at risk. Looking to learn how pipeline integrity pros are modernizing their process? Reach out or explore Technical Toolboxes’ RSTRENG+ software, a tool built for TVC documentation, faster decision making and safer pipelines.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]