Enhancing Asset Integrity: Advanced API 510 & 570 Inspection Techniques

By Kesley Price

SME Webinar on API 510 and API 570 Techniques

In a recent webinar, Jeff Walling shared valuable insights into advanced API 510 and 570 inspection techniques, emphasizing the importance of maintaining asset integrity in pipeline operations. This blog will explore the technical aspects of these inspection standards, their application in the field, and how tools like the API Inspectors Toolbox can enhance the efficiency and accuracy of these inspections.

Understanding API 510 and 570 Standards

API 510 and 570 are critical standards for maintaining the integrity of pressure vessels and piping systems in the petroleum and natural gas industries. These standards provide guidelines for inspection, repair, alteration, and rerating of in-service equipment.

- API 510: Focuses on the inspection, repair, alteration, and rerating of in-service pressure vessels and the pressure relieving devices protecting these vessels. It aims to ensure the safety and reliability of these vessels by providing a framework for regular inspections and necessary maintenance actions.

- API 570: Covers the inspection, repair, alteration, and rerating of metallic piping systems. This standard helps in managing the integrity of piping systems, which are crucial for the safe and efficient transport of hydrocarbons.

Key Pipeline Inspection Techniques

- Visual Inspection – Visual inspections are the first line of defense in detecting potential issues in pressure vessels and piping systems. Inspectors look for signs of corrosion, wear, leaks, and other physical damage that might compromise the system’s integrity.

- Ultrasonic Testing (UT) – Ultrasonic testing is a non-destructive method that uses high-frequency sound waves to detect internal flaws. It is particularly useful for measuring wall thickness and detecting corrosion and erosion.

- Radiographic Testing (RT) – Radiographic testing involves using X-rays or gamma rays to produce images of the internal structure of the equipment. This technique helps in identifying cracks, voids, and other defects that are not visible on the surface.

- Magnetic Particle Testing (MPT) – Magnetic particle testing is used to detect surface and slightly subsurface discontinuities in ferromagnetic materials. It involves magnetizing the surface and applying ferrous particles, which gather around imperfections, making them visible.

- Liquid Penetrant Testing (LPT) – Liquid penetrant testing is a method used to detect surface-breaking defects. It involves applying a liquid dye to the surface, which penetrates any cracks or defects. After a certain period, the excess dye is removed, and a developer is applied, making the defects visible.

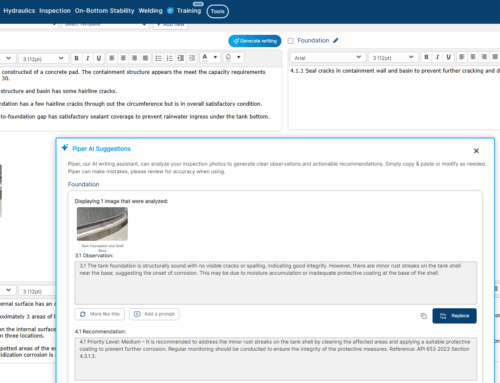

Advanced Tools for API Inspectors

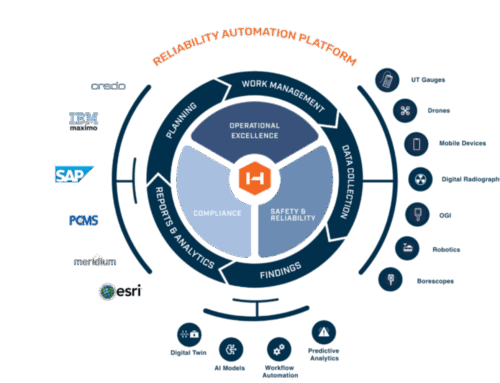

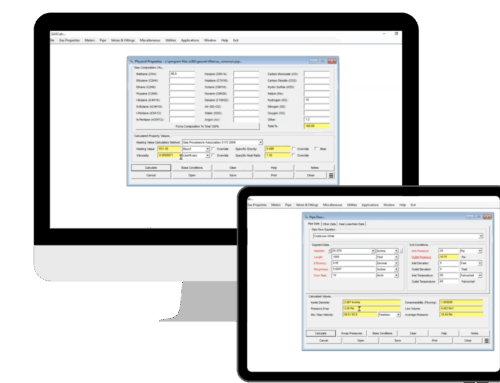

The API Inspectors Toolbox by Technical Toolboxes offers a comprehensive suite of tools designed to streamline the inspection process, ensuring accuracy and compliance with industry standards.

Key Features

- Centralized Data Repository: Integrates all inspection data into one platform, reducing the need for repetitive data entry and minimizing errors.

- Automated Calculations: Performs critical calculations based on API standards, ensuring consistent and accurate results on API 510 and 570.

- Automated Reporting: Generates detailed reports that comply with regulatory requirements, making it easier to maintain traceable, verifiable, and complete (TVC) documentation.

Case Study: Applying Advanced Inspection Techniques

During the webinar, Jeff Walling illustrated the practical application of these advanced inspection techniques through a case study. A large refinery experienced frequent maintenance issues with its pressure vessels and piping systems. By adopting API 510 and API 570 inspection standards and utilizing the API Inspectors Toolbox, the refinery achieved significant improvements in operational reliability and safety.

- Inspection Planning: The refinery used the API Inspectors Toolbox to plan inspections, leveraging automated scheduling and notification features.

- Data Collection and Analysis: Inspectors used advanced NDT techniques, with data collected and analyzed using the toolbox, ensuring comprehensive coverage and accurate defect detection.

- API Reporting and Compliance: The toolbox facilitated the generation of detailed inspection reports, ensuring compliance with API standards and regulatory requirements.

Conclusion

Many Inspectors ask them what tools they can use to calculate remaining life for my tanks and vessels accurately. Advanced API 510 and API 570 inspection techniques are essential for maintaining the integrity of pressure vessels and piping systems in the oil and gas industry. By leveraging tools like the API Inspectors Toolbox, companies can enhance their inspection processes, ensuring safety, compliance, and operational efficiency. Jeff Walling’s insights and the practical applications discussed in his webinar provide a clear roadmap for adopting these advanced techniques and tools in the field.

For more information on how the API Inspectors Toolbox can benefit your inspection processes, visit Technical Toolboxes.

Stay tuned for more technical insights and updates by subscribing to our newsletter or contacting our team for a demo of the API Inspectors Toolbox. Enhance your inspection capabilities today and ensure the integrity of your assets with the latest tools and techniques.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]