Essentials of Pipeline Integrity Management

By Kesley Price

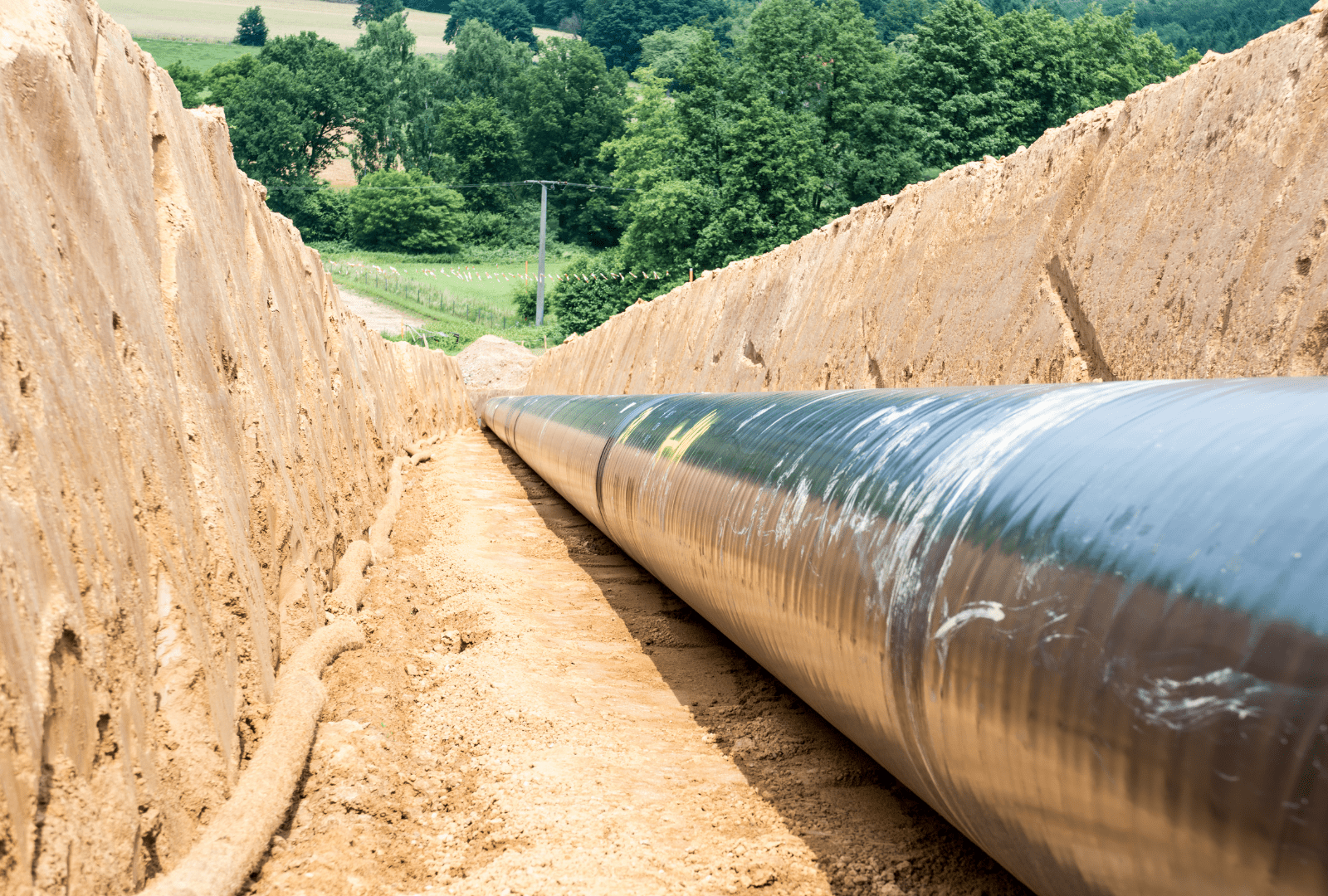

Pipeline integrity management is a vital component in ensuring the safe, reliable, and efficient operation of pipelines, which are the backbone of the energy infrastructure. With a focus on preventing leaks, minimizing risks, and maintaining compliance, this discipline combines the use of cutting-edge technology, risk assessment, and best practices to extend the life of pipeline assets. In this post, we’ll explore the key elements of pipeline integrity management and highlight some essential tools and techniques.

Understanding Pipeline Integrity Management

At its core, pipeline integrity management refers to the systematic approach used to monitor and maintain the safe operation of pipelines. This involves assessing potential risks, inspecting pipeline components, and implementing preventive measures to avoid pipeline failures. Given the high-stakes nature of pipelines, which transport critical resources such as oil, gas, and water, effective management programs are essential to prevent accidents that can cause significant environmental and economic damage.

Key Components of Pipeline Integrity Management

- Risk Assessment

Risk assessment is a fundamental aspect of pipeline integrity management. By analyzing factors such as corrosion, material fatigue, and third-party interference, operators can identify potential threats to the system and prioritize maintenance efforts. Tools like the AC Mitigation PowerTool provide comprehensive assessments for pipelines running near high-voltage power lines, helping to model and mitigate risks of AC-induced corrosion. - Pipeline Inspection Techniques

Inspection is the backbone of integrity management programs. Technologies like In-Line Inspection (ILI) and hydrostatic testing play a critical role in detecting internal and external pipeline defects. The Hydrotest PowerTool from Technical Toolboxes is designed to simplify the hydrostatic testing process by ensuring full compliance with federal regulations (CFRs 192 and 195) and automating record-keeping to meet “Traceable, Verifiable, and Complete” (TVC) standards. - Corrosion Control

Corrosion is one of the leading causes of pipeline failures. Effective mitigation strategies include the use of coatings, cathodic protection systems, and advanced monitoring software like the AC Mitigation PowerTool. This tool models AC-induced current on buried pipelines and provides solutions to minimize corrosion risk, especially for pipelines in proximity to electrical power lines. - Data-Driven Decisions and Automation

Modern pipeline integrity management is increasingly relying on data-driven solutions. The Pipeline HUB offers a centralized platform that integrates data across engineering disciplines, helping operators to automate complex calculations, visualize assets, and generate compliance reports effortlessly. Tools like the RSTRENG+ further streamline the process by automating workflows and performing complex analyses to determine the remaining strength of corroded pipes. - Compliance and Best Practices

Integrity management programs must adhere to industry standards and regulations to ensure safety and avoid costly penalties. Software solutions like the Pipeline Toolbox (PLTB) ensure that all calculations and assessments comply with standards such as PHMSA, DOT, CSA, and ASME. These tools facilitate the maintenance of accurate data records and ensure adherence to best practices throughout the pipeline’s lifecycle.

Best Practices in Integrity Management

- Regular Inspections and Testing

Regularly scheduled inspections, including hydrostatic testing and in-line inspections, are crucial in identifying potential issues early. Integrating tools such as Pipeline Toolbox and Hydrotest PowerTool can expedite this process while ensuring full compliance with regulatory requirements. - Risk-Based Maintenance Strategies

Implementing a risk-based approach to pipeline maintenance allows operators to prioritize high-risk areas and allocate resources efficiently. This includes using advanced modeling tools like the AC Mitigation PowerTool to predict where corrosion or mechanical failure is most likely to occur. - Collaborative Data Management

A centralized data management platform like the Pipeline HUB enhances collaboration across engineering teams. It ensures that all data is consistent and up to date, allowing for better decision-making and streamlined project management. - Advanced Corrosion Mitigation Techniques

Mitigating corrosion is essential for maintaining pipeline integrity. Solutions such as the AC Mitigation PowerTool and RSTRENG+ help operators model corrosion effects and make informed decisions about preventive measures.

Conclusion

Pipeline integrity management is a complex but critical process that ensures the safety, efficiency, and longevity of pipeline infrastructure. By leveraging advanced tools, such as the AC Mitigation PowerTool, Pipeline HUB, and RSTRENG+, operators can proactively manage risks, optimize maintenance strategies, and maintain compliance with regulatory standards. Implementing these best practices and adopting cutting-edge technology will ensure the continued safe operation of pipelines in an increasingly demanding energy environment.

For more insights and tools to manage pipeline integrity, explore the resources provided by Technical Toolboxes.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]