How RSTRENG+ Calculations Support Modern Pipeline Integrity Management

By Joe Pikas

In pipeline engineering, ensuring the integrity and safety of pipelines is of utmost importance. It requires an understanding of various factors that contribute to corrosion and the weakening of pipeline infrastructure. The challenges in maintaining pipeline integrity are many, ranging from detecting and assessing corrosion defects accurately to making informed decisions about pipeline repairs or replacements. This is where RSTRENG+ becomes an indispensable tool for engineers.

A Quick Background on the RSTRENG+ Software Application

RSTRENG (short for “remaining strength”) was originally developed by the Pipeline Research Council International (PRCI) with input from operators and service providers. It’s considered a more accurate, less overly conservative approach to pipeline integrity compared to older methods of corrosion analysis and is the only level 2 inspection methodology sanctioned by the US Code of Federal Regulations (CFR). Technical Toolboxes builds on top the original RSTRENG application developed by PRCI with a mix of value-added tools covered below.

ASME B31.G and Modified B31.G are Level 1 calculations that use only the maximum depth and length of the pitting, and were the previous methods for calculating remaining strength of a pipe prior to RSTRENG being developed. These calculations are very conservative results that can create a costly list of repairs or replacement projects on the pipeline. Reducing the conservative assessments with accuracy ensures the integrity of the pipeline that reduces uncertainty, costs which offset a decrease in repair expenses.

The Challenges Without RSTRENG+

Without a comprehensive tool like RSTRENG+, engineers face several significant challenges:

- Difficulty in Accurate Defect Assessment: Determining the remaining strength of corroded pipes can be highly complex, involving numerous variables.

- Compliance and Safety Risks: Failing to comply with regulatory standards such as the PHMSA Mega Rule can lead to severe safety and environmental risks, not to mention potential legal and financial repercussions.

- Inefficient Repair Decision-Making: Without clear insights into the integrity of pipelines, engineers may over or underestimate the need for repairs, leading to unnecessary expenditures or risking pipeline failure.

- Time-Consuming Processes: Traditional methods of assessing pipeline integrity are often time-consuming and prone to human error, reducing operational efficiency.

Why RSTRENG+ Holds Immense Value

RSTRENG+ addresses these challenges head-on by providing a robust platform for the accurate and efficient assessment of pipeline corrosion and its impact on pipeline integrity. Here are several reasons why RSTRENG+ is invaluable:

- Accurate Remaining Strength Calculations: Leveraging the only Level 2 methodology sanctioned by the Code of Federal Regulations, RSTRENG+ offers precise calculations of a pipeline’s remaining strength over extended lengths of pipe.

- Compliance with Industry Regulations: The tool ensures all calculations and methodologies align with current industry standards and regulations, aiding compliance and safety.

- Streamlined Repair Decision-Making: By providing detailed insights into the integrity of pipelines, RSTRENG+ enables engineers to make informed decisions about necessary repairs or replacements, optimizing both costs and safety.

- Time and Cost Savings: The automation and accuracy of RSTRENG+ reduces manual workloads and the potential for error, saving significant time and resources in pipeline integrity management projects.

Key Features of RSTRENG+

In addition to the calculation engine RSTRENG+ is packed with value-added features designed to streamline the pipeline integrity management process:

- Batch Run Capability: Engineers can analyze up to 50 cases simultaneously, significantly accelerating project timelines.

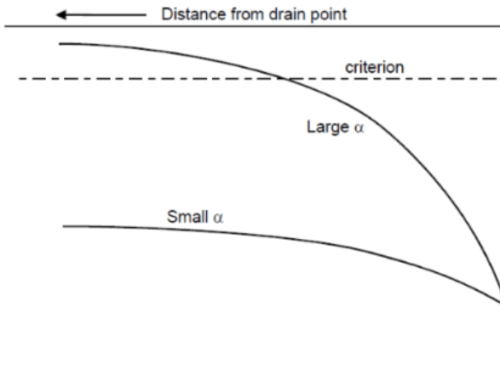

- Sensitivity Analysis: Adjust inputs within realistic ranges and observe the effects on the output, determining which variables have the most significant impact on pipeline integrity.

- Zero-Out Method: This advanced feature allows for pinpointing effective areas of corrosion that need repair, facilitating compliance with the Maximum Allowable Operating Pressure (MAOP). This feature locates the areas of concern (threats) that need to be mitigated or fixed.

- Comprehensive Reporting: RSTRENG+ simplifies the audit process and compliance with Traceable, Verifiable, and Complete (TVC) recordkeeping requirements under the Pipeline and Hazardous Materials Safety Administration (PHMSA).

In conclusion, RSTRENG+ stands as a cornerstone tool for pipeline engineers focused on corrosion and integrity management. Its sophisticated features not only ensure the safety and compliance of pipeline operations but also offer significant time and cost efficiencies. As the industry continues to evolve, RSTRENG+ remains an essential asset in the engineer’s toolkit, enabling them to navigate the complexities of pipeline integrity management with confidence and precision.

Stay ahead of pipeline integrity challenges with RSTRENG+.

Enhance your expertise in pipeline integrity assessment with our live virtual classes on ‘RSTRENG and Defect Assessment.’ Gain certification and Professional Development Hours (PDHs) while ensuring your skills are up to date with industry standards. Check out our full course list here.

For more insights and to explore the full capabilities of RSTRENG+, visit our website at: https://technicaltoolboxes.com/rstreng-plus/.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]