Intro to AI in Midstream:

What’s Here, What’s Next, and What Still Needs You

By Marc Dungler

AI is rapidly reshaping the midstream oil and gas industry—but probably not in the way you think.

We’re not talking about robots replacing field engineers or algorithms running pipelines unsupervised. We’re talking about smarter software that helps engineers, inspectors, and operations leaders make faster, safer, and more informed decisions, especially as regulatory scrutiny, asset complexity, and data volume grow.

If your teams still rely on spreadsheets and siloed tools, it’s time to look at how AI is already helping midstream teams cut risk, reduce manual work, and boost compliance.

Welcome to the new era of pipeline intelligence, driven by AI you can trust.

What Is AI in Midstream, Really?

Forget the buzzwords. In midstream pipeline operations, AI is not about flashy tools or hype-driven tech. It’s about turning massive volumes of complex data into decisions that reduce risk, improve safety, and keep operations running smoothly.

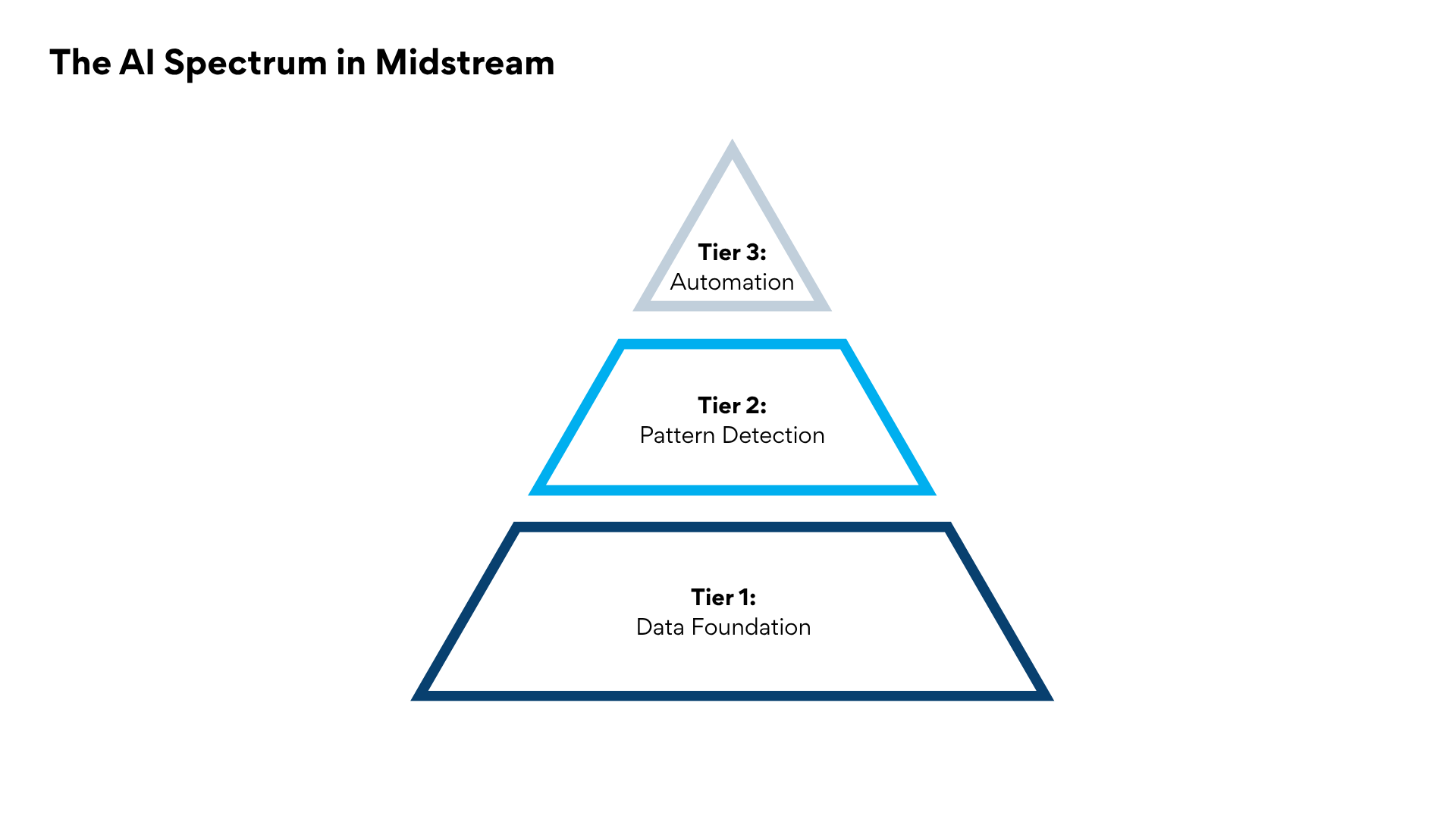

At Technical Toolboxes, we think of AI not as a single capability, but as a progression built on three foundational pillars. Each step builds toward smarter, faster, and more scalable pipeline management.

-

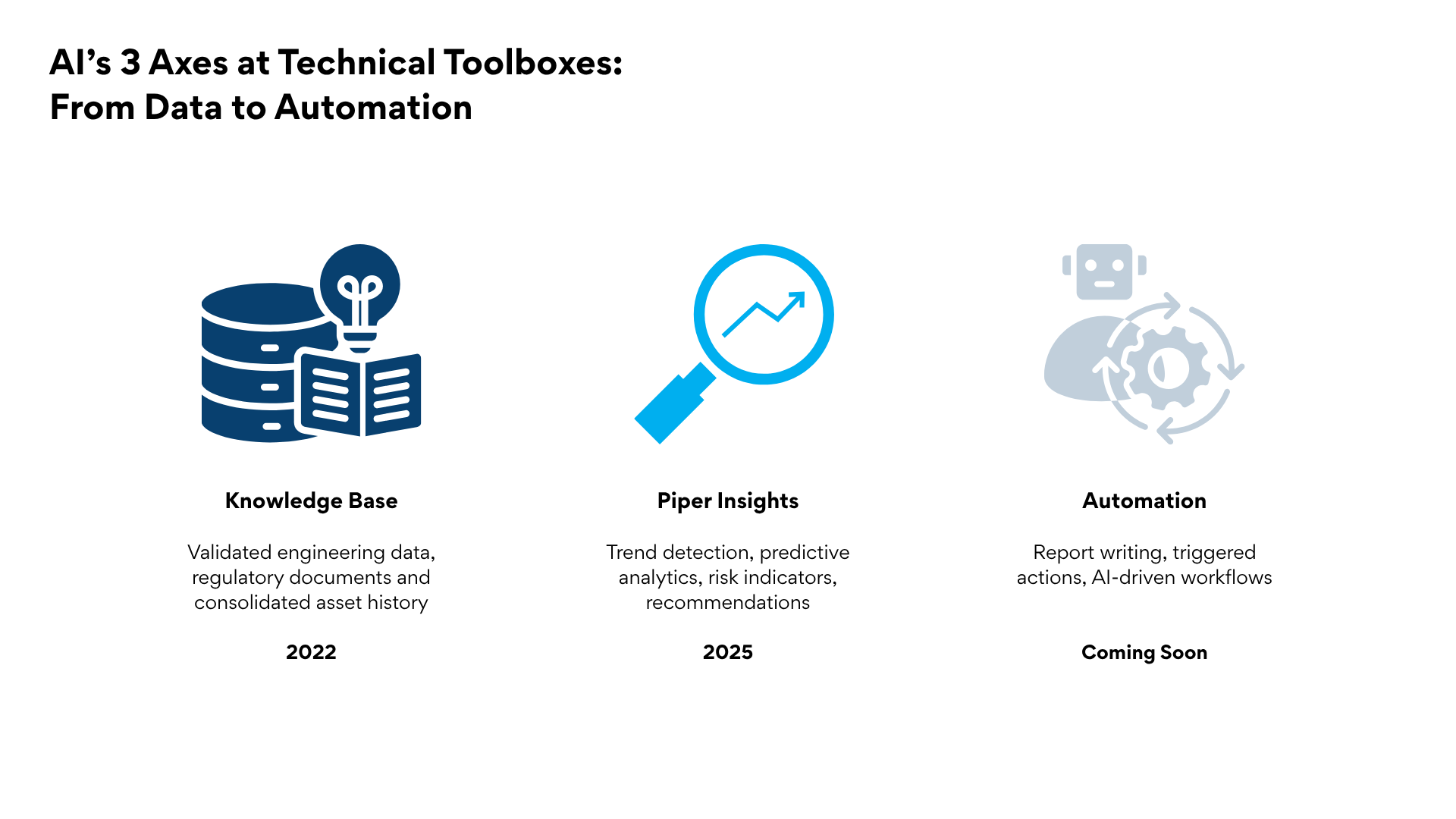

Knowledge Base – Data Foundation

Everything starts with data. But not just any data—centralized, validated, and structured engineering information.

Without a solid data foundation, AI can’t do much. This is where tools like Pipeline HUB and Pipeline Toolbox (PLTB) come in—consolidating asset data, calculation history, regulatory documents, and field reports into a single source of truth.

Several major oil and gas companies, including those in the midstream sector, are adopting AI-driven knowledge bases to support decision-making and retain institutional knowledge, especially as experienced engineers retire and new talent enters. While many of these platforms are developed in-house and not marketed publicly, the trend is unmistakable.

Custom Internal Knowledge Bases: Operators like Shell, BP, and Chevron are building proprietary systems that centralize operational knowledge and engineering standards for internal use. These systems power predictive maintenance, asset management, and compliance reporting across upstream and midstream operations. 1, 2, 3

Whether through branded tools or internal systems, the goal is the same: make trusted engineering knowledge available and usable across the enterprise. That’s the baseline for all effective AI in midstream. This trend is expected to grow as digital transformation and workforce changes continue to drive demand for centralized, AI-powered knowledge sharing in the sector.4,5,6

-

Insights – Pattern Detection

Once your data foundation is in place, AI can begin generating real value by surfacing trends, anomalies, and patterns that humans would otherwise miss.

This is where Piper AI Insights operates—transforming raw data into decision-ready intelligence. Piper scans for issues like MAOP deviations, abnormal corrosion rates, or pipeline segments trending toward integrity thresholds—often before those issues show up on a report.

Take predictive analytics, for example. Shell’s deployment of machine learning in midstream operations allowed them to forecast equipment failures before they caused downtime—a move that cut maintenance costs and let engineers focus on solving problems rather than hunting for them. 1,7,8

That’s the kind of shift insights-driven AI enables: from reactive to proactive, from gut feel to data-informed action.

-

Automation

The next evolution is AI that not only identifies problems, but acts on them.

This is the frontier of Tier 3 AI, and where Technical Toolboxes is actively investing. In the near future, AI agents will draft pipeline inspection reports, recommend mitigation actions based on anomalies, and even notify stakeholders before a failure risk escalates.

Technologies like Robotic Process Automation (RPA) are already being used in oil and gas to automate repetitive, rule-based tasks, such as document handling, test report formatting, and data entry. In pipeline operations, these same tools can streamline inspection workflows, automate compliance reporting, or generate test plans based on asset history.9

RPA reduces closing time and minimizes human errors, especially in workflows that require precision and consistency, like PHMSA recordkeeping or MAOP verification documentation. What once took days to compile can now be triggered automatically, saving engineers hours of redundant work while ensuring data accuracy.

Imagine an AI assistant that knows when a pipeline section is due for hydrotesting, prepares the plan, and auto-generates the reporting package—aligned with PHMSA’s latest rules. That’s not a dream scenario. It’s where the industry is headed.

AI in Action: Real-World Case Studies

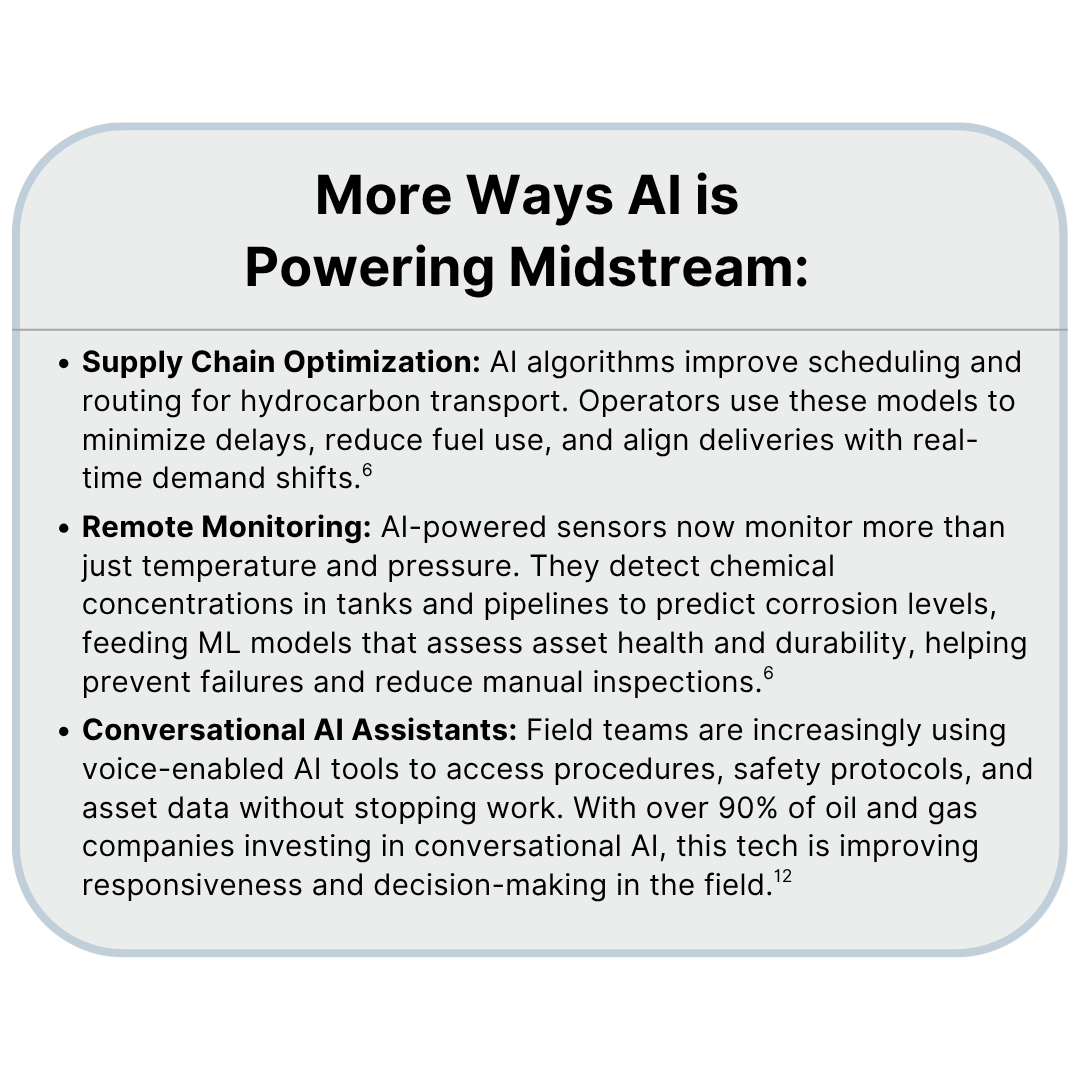

While the future of intelligent automation is just beginning to take shape, some AI applications are already delivering measurable impact in the field. From inspection to maintenance to throughput optimization, midstream operators are putting AI into action, proving that it’s not just possible, but practical.

Let’s look at a few real-world examples where AI is already transforming how pipeline systems are managed.

-

- Automated Drone Inspections: Leading midstream operators now deploy AI-powered drones for aerial pipeline inspections. These drones use computer vision to detect corrosion, leaks, and encroachment in real time, reducing unplanned downtime and enabling faster remediation.10

-

- Predictive Maintenance at Shell: Shell leverages machine learning to monitor equipment health across its midstream assets. By analyzing sensor data, AI forecasts potential failures, allowing maintenance teams to act proactively and reduce costly outages.11

- Predictive Maintenance at Shell: Shell leverages machine learning to monitor equipment health across its midstream assets. By analyzing sensor data, AI forecasts potential failures, allowing maintenance teams to act proactively and reduce costly outages.11

-

- Pipeline Throughput Optimization: AI-driven models analyze real-time and historical flow data to dynamically adjust pump settings and routing. This maximizes throughput while minimizing energy use and wear, helping operators quickly adapt to changing demand.4

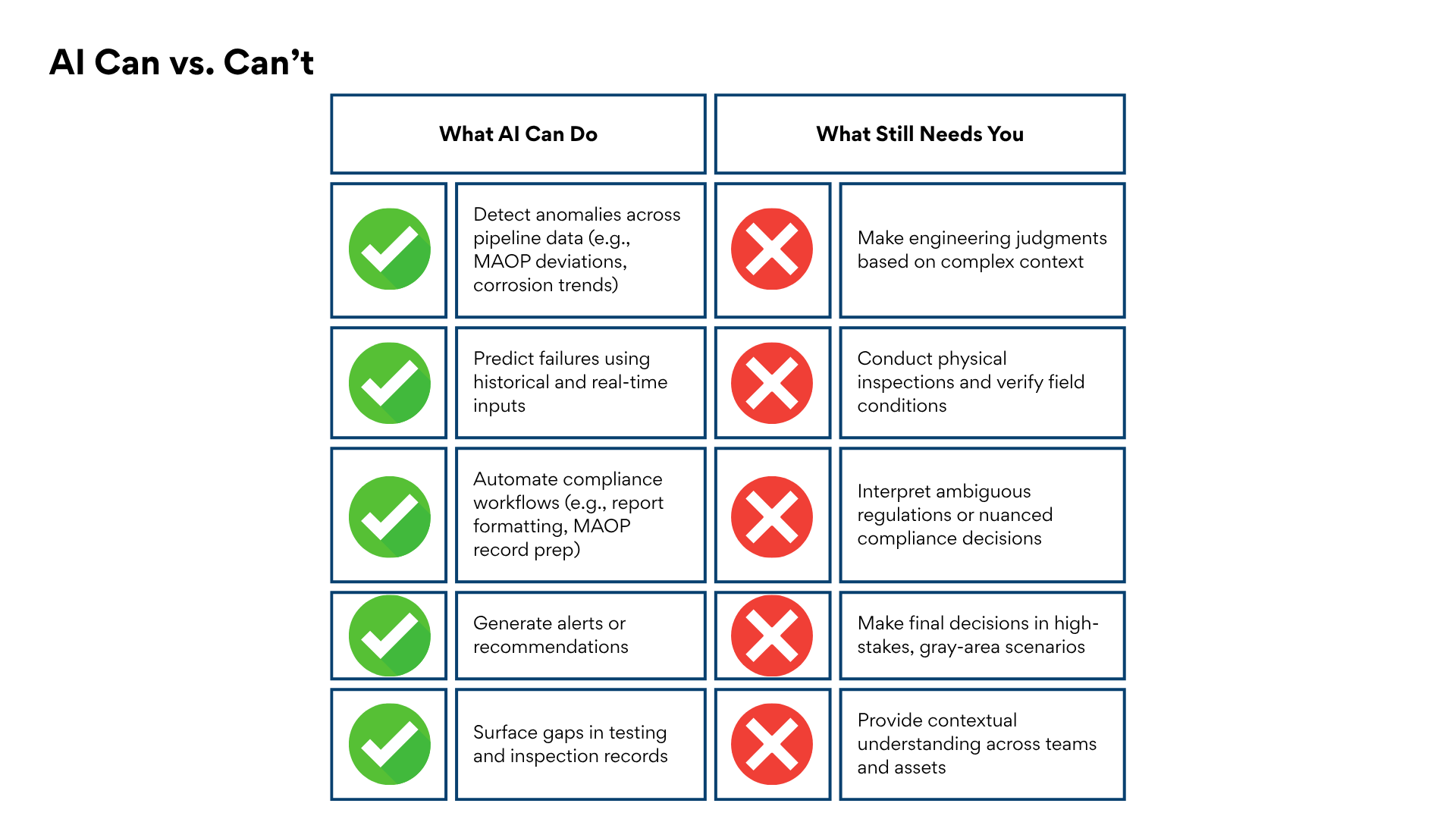

Where AI Works and Where It Doesn’t

Let’s be honest—AI isn’t magic. There are clear limitations, and understanding them is key to using it well.

✅ Where AI helps:

- Pattern recognition across large data sets

- Identifying outliers and anomalies

- Benchmarking and predictive reporting

- Speeding up workflows (e.g., report generation, test planning)

❌ Where it doesn’t:

- Replace human engineering judgment

- Conduct physical inspections or verifications

- Interpret regulatory decisions

The goal isn’t to replace people, it’s to remove bottlenecks.

Getting Started: Is Your Organization AI-Ready?

You don’t need to overhaul everything. Start small, and start with insights.

Here’s how to build momentum:

✅ Start with centralized data. If your pipeline data lives in scattered spreadsheets, standalone engineering tools, or outdated legacy systems, the first step is to clean it up, and that doesn’t just mean reorganizing a file folder. It means establishing a single source of truth for your pipeline asset data, test records, calculations, inspection histories, and regulatory documentation. In an ideal scenario, your team should be able to:

- Access the same validated datasets across engineering, integrity, and compliance

- Eliminate duplicate entry and version control issues

- Easily query historical records to support MAOP verification or corrosion tracking

- Standardize workflows so calculations and decisions are based on consistent data

This is where Pipeline HUB plays a critical role. As the backbone of Technical Toolboxes’ software suite, Pipeline HUB acts as your central system of record, bringing together asset data, GIS integration, engineering calculations, and report history into one shared environment.

By consolidating your pipeline intelligence in Pipeline HUB, you create a clean foundation that AI tools like Piper AI Insights can build on—surfacing trends, risks, and outliers without relying on disconnected data sources.

Centralizing your data isn’t just a tech upgrade—it’s the prerequisite for any successful AI initiative.

✅ Use tools like Piper AI to surface quick wins—for example, identifying patterns in MAOP deviations or corrosion rates.

Once your data is centralized in a system like Pipeline HUB, the next step is putting that data to work. AI doesn’t need a mountain of custom development to deliver value—it just needs a clean foundation and the right use cases.

Piper AI Insights is designed to scan your operational and historical pipeline data for early indicators of risk. That might look like:

- Identifying pipeline segments where MAOP variances are trending outside expected limits

- Flagging regions of the network where corrosion rates are accelerating over time

- Noticing gaps in testing history or missed documentation needed for PHMSA compliance

- Comparing recent inputs to historical norms to detect anomalies before they become failures

Because Piper AI is built on top of the Pipeline HUB, it doesn’t rely on spreadsheets or disconnected inputs. Instead, it draws from a shared, validated data environment, which means insights are more accurate, trustworthy, and actionable.

These “quick wins” aren’t just about faster analysis—they’re about spotting issues early, reducing regulatory exposure, and letting your engineers focus their time where it matters most.

✅ Build trust across teams. AI isn’t just for engineers. Share insights with integrity, compliance, and operations.

To get the full value from AI, the insights it generates need to reach more than just the engineering team. Integrity, compliance, operations, and even executive leadership all depend on reliable data to make high-stakes decisions.

By centralizing your data in Pipeline HUB and layering Piper AI Insights on top, you’re not just making engineers faster—you’re making insights accessible to everyone who needs them.

For example:

- Integrity teams can quickly identify which pipeline sections are trending toward failure thresholds and prioritize inspections accordingly.

- Compliance teams can see gaps in historical documentation or PHMSA-related records before an audit, reducing the scramble to prepare.

- Operations teams can use AI-generated trendlines to better understand where to direct field resources or adjust schedules.

- Leadership gains higher confidence in the data used for risk decisions, investment planning, or reporting to regulators and partners.

When teams are all working from the same system of record—and seeing the same AI-powered insights—you reduce miscommunication, prevent duplicate work, and build organizational alignment.

AI becomes more than a tool—it becomes a trust accelerator.

Want to know where you stand?

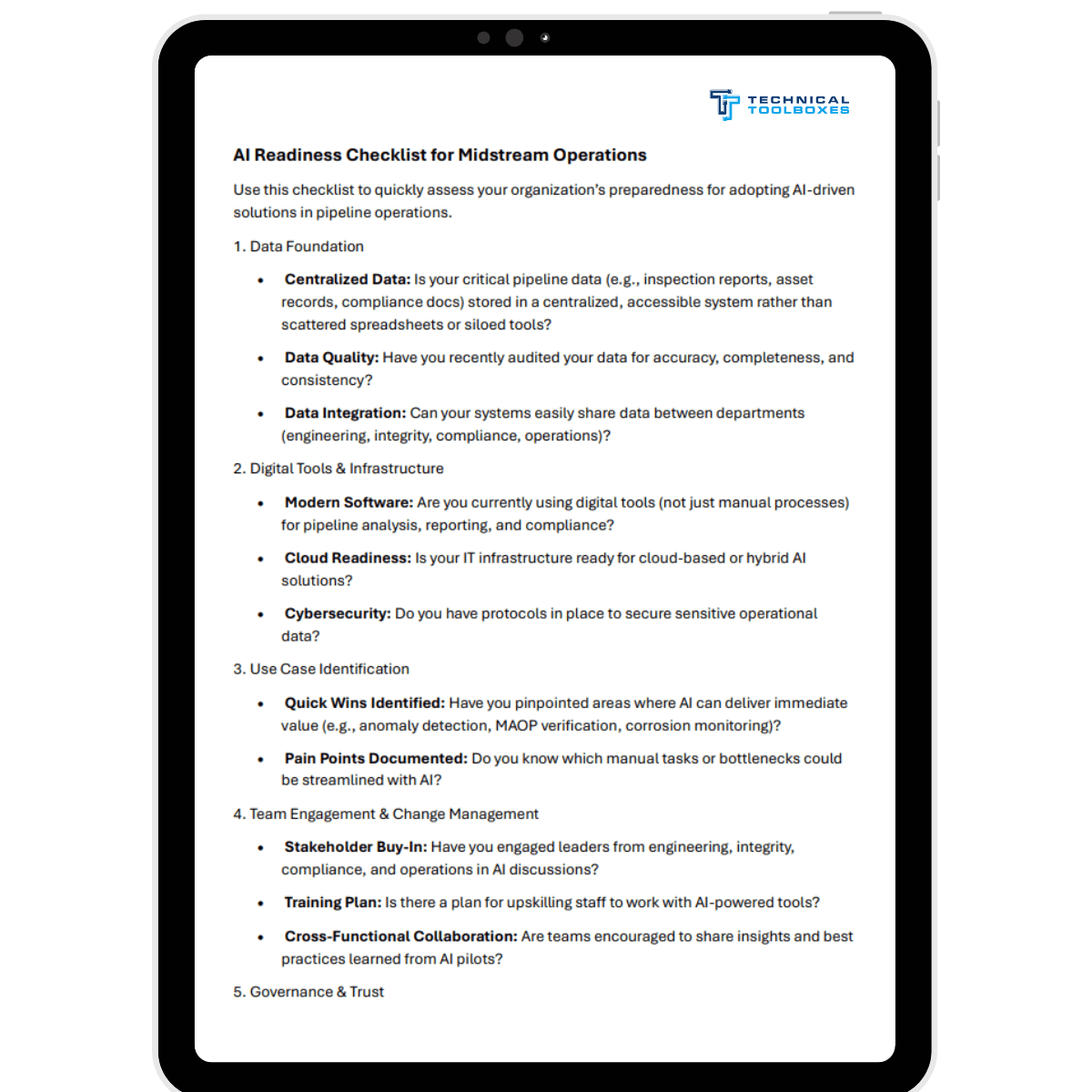

We’ve created a quick AI Readiness Checklist to help you identify gaps and opportunities.

Conclusion: The Next Era of Midstream Belongs to the Proactive

AI isn’t coming to midstream—it’s already here. From drones in the field to predictive alerts in the control room, the companies seeing the greatest impact aren’t waiting for AI to mature—they’re putting it to work on the problems they face today.

But here’s the truth: AI only works when the foundation is in place. That means connected data. Shared insights. And a clear roadmap for moving from reactive maintenance to proactive intelligence.

Technical Toolboxes is building that foundation with tools like Pipeline HUB and Piper AI Insights. Together, they give operators the ability to centralize knowledge, surface risks faster, and build toward intelligent automation—one insight at a time.

The next phase of midstream isn’t about replacing people. It’s about amplifying expertise, reducing risk, and helping your teams focus on what matters most.

If your pipeline operations are still buried in disconnected tools and legacy workflows, it’s time to take the first step.

Smarter decisions start with better visibility. AI is how you get there.

Ready to explore AI for your midstream operations?

→ Download the AI Readiness Checklist

Let’s build the future of pipeline intelligence together.

Sources:

- Shell: Machine learning in predictive maintenance – https://www.youtube.com/watch?v=NjLKDauz6qE&t=2s

- BP: Investment in AI technologies – https://www.bp.com/en/global/corporate/news-and-insights/press-releases/bp-invests-in-new-artificial-intelligence-technology.html

- Chevron: AI powering reliable energy and operations – https://www.chevron.com/newsroom/2025/q1/chevron-uses-ai-to-bring-reliable-energy-to-data-centers

- Alvarez & Marsal. “Operationalizing AI in Midstream Oil and Gas: Use Cases, Benefits & Barriers.” https://www.alvarezandmarsal.com/thought-leadership/operationalizing-ai-in-midstream-oil-and-gas-use-cases-benefits-barriers

- Appinventiv. “Artificial Intelligence in Oil and Gas Industry: Use Cases, Benefits & Challenges.” https://appinventiv.com/blog/artificial-intelligence-in-oil-and-gas-industry

- Citation Compliance: Role of AI in the Oil & Gas Value Chain – https://www.citationcompliance.com/blog/role-of-ai-in-the-oil-and-gas-value-chain-midstream-downstream-segment

- Instinctools. “Hype Aside: Real-World Use Cases of Artificial Intelligence in the Oil and Gas Industry” https://www.instinctools.com/blog/ai-in-oil-and-gas-industry/

- Sand Technologies. “Drilling Down: How AI Is Changing the Future of Oil and Gas.” https://www.sandtech.com/insight/drilling-down-how-ai-is-changing-the-future-of-oil-and-gas/

- Kissflow. “Top 7 Oil and Gas Technology Trends to Watch in 2024.” https://kissflow.com/solutions/oil-and-gas/oil-and-gas-technology-trends

- ImageVision AI. “Pipeline Inspection with Drones and Computer Vision in Oil and Gas.” https://imagevision.ai/blog/pipeline-inspection-with-drones-and-computer-vision-in-oil-and-gas

- Journal of Petroleum Technology (SPE). “Shell Scales Predictive Maintenance to 10,000 Pieces of Equipment.” https://jpt.spe.org/shell-scales-predictive-maintenance-to-10-000-pieces

- Druid AI. “Applications of Conversational AI in Oil & Gas.” https://www.druidai.com/blog/applications-of-conversational-ai-in-oil-gas

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]