Introduction to RSTRENG: Critical for Corrosion Mitigation

By Joe Pikas

In the field of pipeline integrity management, staying ahead of corrosion and metal loss is paramount for ensuring the safety and efficiency of pipeline operations. One of the most reliable methods for assessing the remaining strength of corroded pipelines is the RSTRENG (Remaining Strength of Corroded Pipe) methodology, developed and endorsed by the Pipeline Research Council International (PRCI). Understanding the RSTRENG calculation principles and how they support modern pipeline integrity management is essential for pipeline engineers and integrity professionals.

What is RSTRENG?

RSTRENG is a Level 2 assessment method sanctioned by the Code of Federal Regulations (CFR) 192 Gas and 195 Liquid to determine the remaining strength of corroded pipelines. This method provides a more accurate evaluation than traditional methods like ASME B31G, especially for extensive metal loss and complex corrosion profiles. RSTRENG allows engineers to assess the safe operating pressure, failure pressure, and remaining strength of a pipeline segment, which is crucial for making informed maintenance and repair decisions.

How RSTRENG Calculations Support Pipeline Integrity

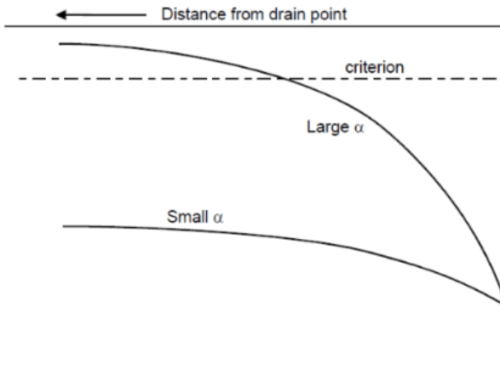

RSTRENG calculations consider the corrosion morphology, effective length, and depth, providing a detailed analysis of a pipeline’s condition. This methodology helps in identifying areas that need immediate attention, prioritizing maintenance activities, and extending the pipeline’s operational life. The accuracy and reliability of RSTRENG have made it a preferred choice for pipeline integrity assessments across the industry.

The Importance of RSTRENG+ by Technical Toolboxes

While RSTRENG provides a solid foundation for corrosion assessment, Technical Toolboxes’ RSTRENG+ enhances this methodology with advanced features and automated workflows as a regulatory compliance tool for pipeline corrosion. RSTRENG+ is built on the robust RSTRENG engine, offering additional functionalities that streamline the integrity analysis process and improve accuracy.

Key Features of RSTRENG+

- Zero-Out Method: This feature allows engineers to pinpoint all multiple effective areas of corrosion that need repair, using field inspection data to operate at the desired Maximum Allowable Operating Pressure (MAOP)

- Batch Run: An advanced feature enabling the analysis of up to 50 cases simultaneously, enhancing efficiency and decision-making speed

- Non-PRCI Calculations: These calculations include reassessment interval determination and remaining strength calculations (SHELL-92, DNV, PCORRC, API 579), providing flexibility to accommodate various scenarios

- Compliance with Mega Rule: RSTRENG+ ensures adherence to the Mega Rule under the Pipeline and Hazardous Materials Safety Administration (PHMSA), meeting the requirements for traceable, verifiable, and complete (TVC) documentation. To be compliant in meeting the pipeline SMYS material validation requirements Technical Toolboxes is planning to add a checkbox for this purpose.

Why RSTRENG+ is Essential for Corrosion Mitigation

The ability to determine the safe operating pressure, remaining strength, and failure pressure of corroded pipes is crucial for minimizing the risk of catastrophic failures. RSTRENG+ not only accelerates project schedules through its automated workflows but also improves accuracy and confidence in integrity assessments. By reducing manual input and leveraging advanced calculations, RSTRENG+ helps pipeline operators maintain high safety standards while optimizing maintenance costs.

Conclusion

Incorporating RSTRENG+ into your pipeline integrity management strategy is a proactive step towards effective corrosion mitigation. By utilizing these advanced tools, pipeline engineers can ensure the continued safety, reliability, and efficiency of pipeline operations. Technical Toolboxes remains at the forefront of providing innovative solutions that support the evolving needs of the pipeline industry.

By leveraging the expertise of PRCI-endorsed methodologies and the advanced features of Technical Toolboxes’ RSTRENG+, pipeline operators can ensure their infrastructure remains robust and resilient against the challenges posed by corrosion.

For more information on RSTRENG+ and how it can benefit your pipeline integrity management efforts, visit Technical Toolboxes.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]