Navigating API Standards for Pipeline Integrity: A Comprehensive Guide

By Kesley Price

In the world of pipeline engineering, ensuring pipeline integrity is paramount for both safety and operational efficiency. Adhering to API Standards plays a critical role in maintaining these benchmarks, guiding engineers and operators in the design, construction, operation, and maintenance of pipelines. This Pipeline Integrity Guide will help you navigate the intricacies of API Standards and compliance, empowering your team to ensure that your pipelines operate safely, efficiently, and within the bounds of API Regulations.

Understanding API Standards for Pipeline Safety

API, the American Petroleum Institute, has developed a series of standards that outline best practices and regulatory compliance for the petroleum and natural gas industries. These API Pipeline Safety Standards include requirements for materials, design, construction, testing, inspection, and maintenance of pipelines. Standards like API 1104 focus on welding and inspection processes, ensuring that pipelines are welded safely and effectively for long-term reliability. API standards cover various aspects of pipeline operations and are regularly updated to reflect the latest technological advancements and safety requirements.

Key API Standards for Pipeline Integrity

- API 1104: This standard is essential for pipeline welding. It includes guidelines for welding procedures, qualifications, inspection, and the acceptance criteria for weld imperfections. This standard is crucial for both liquid and gas pipelines, ensuring the integrity of welds to prevent leaks and other failures.

- API 1102: Focused on pipeline crossings, this standard provides guidelines for assessing the impact of surface loads on buried pipelines. It ensures that pipelines maintain their integrity when exposed to external forces like vehicles or equipment moving overhead.

- API 579: Part of the Fitness-For-Service (FFS) standards, API 579 outlines the assessment procedures for existing pipelines that may have suffered damage or degradation over time. It provides a framework for determining if a pipeline can continue to operate safely or if repairs or replacements are necessary.

These standards form the backbone of pipeline safety and operational protocols. Engineers and inspectors working on pipelines should be well-versed in these API regulations to ensure compliance and safety across all stages of the pipeline lifecycle.

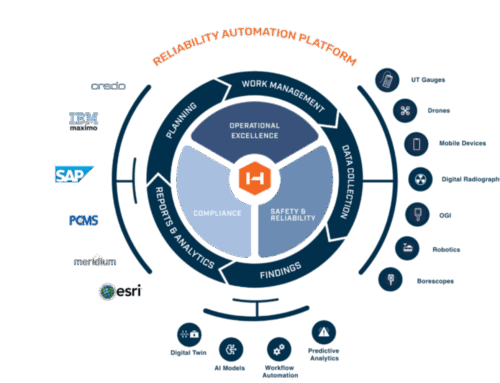

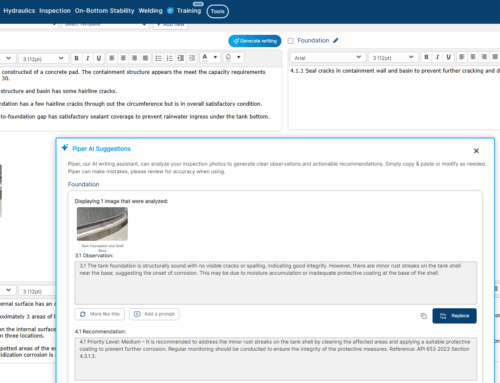

Implementing API Standards with Technical Toolboxes Solutions

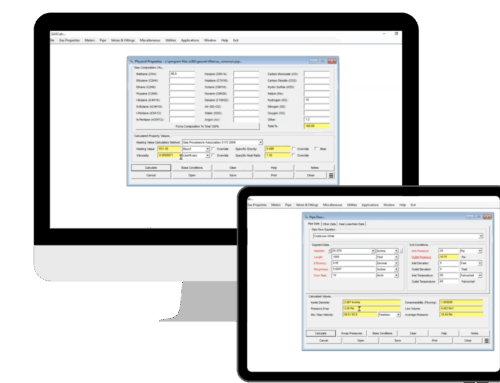

While understanding the standards is one thing, implementing them effectively is another. This is where tools like Technical Toolboxes’ API Toolbox come into play. This software simplifies the application of API standards across inspections and maintenance, reducing the time and effort needed to comply with complex regulations.

The Pipeline Toolbox (PLTB), built on the Pipeline HUB platform, includes a suite of over 250 pipeline-specific calculations. These tools ensure that pipeline integrity is maintained in compliance with federal and industry regulations like PHMSA and ASME, among others. PLTB provides automation features that reduce manual data entry errors, speeding up calculations and ensuring compliance through built-in quality checks.

The Hydrotest PowerTool is another example, which enables pipeline engineers to plan and verify hydrostatic testing for new and existing pipelines, ensuring compliance with API standards like CFR 192 and 195.

Ensuring Compliance with API Standards

Meeting API Compliance Standards involves more than just following a checklist. Engineers must conduct regular inspections, tests, and assessments throughout the pipeline’s operational life. Compliance software like RSTRENG+ provides engineers with tools to calculate the remaining strength of corroded pipelines and ensure ongoing integrity. Built-in features like Batch Run and the Zero-Out Method facilitate compliance with API standards, reducing the risk of catastrophic failures.

Comprehensive API Guide to Pipeline Safety

Ensuring compliance with API Standards is critical for pipeline safety, reducing operational risks, and protecting the environment. Tools like Technical Toolboxes’ Pipeline Toolbox, API Inspectors Toolbox, and Hydrotest PowerTool are designed to help pipeline engineers and inspectors meet these standards efficiently and accurately.

By leveraging these advanced software solutions, your team can not only navigate API Regulations with confidence but also ensure that your pipeline systems remain safe, reliable, and compliant throughout their operational lifespan.

By following this Comprehensive API Guide, you are taking the necessary steps to ensure that your pipelines operate safely and within regulatory compliance, safeguarding both your assets and the environment.

For more detailed information on how Technical Toolboxes can help you with API compliance, visit our website.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]