Navigating the Depths: Mastering HDD Techniques for Optimal Pipeline Planning

By David Willoughby

Introduction to Horizontal Directional Drilling (HDD)

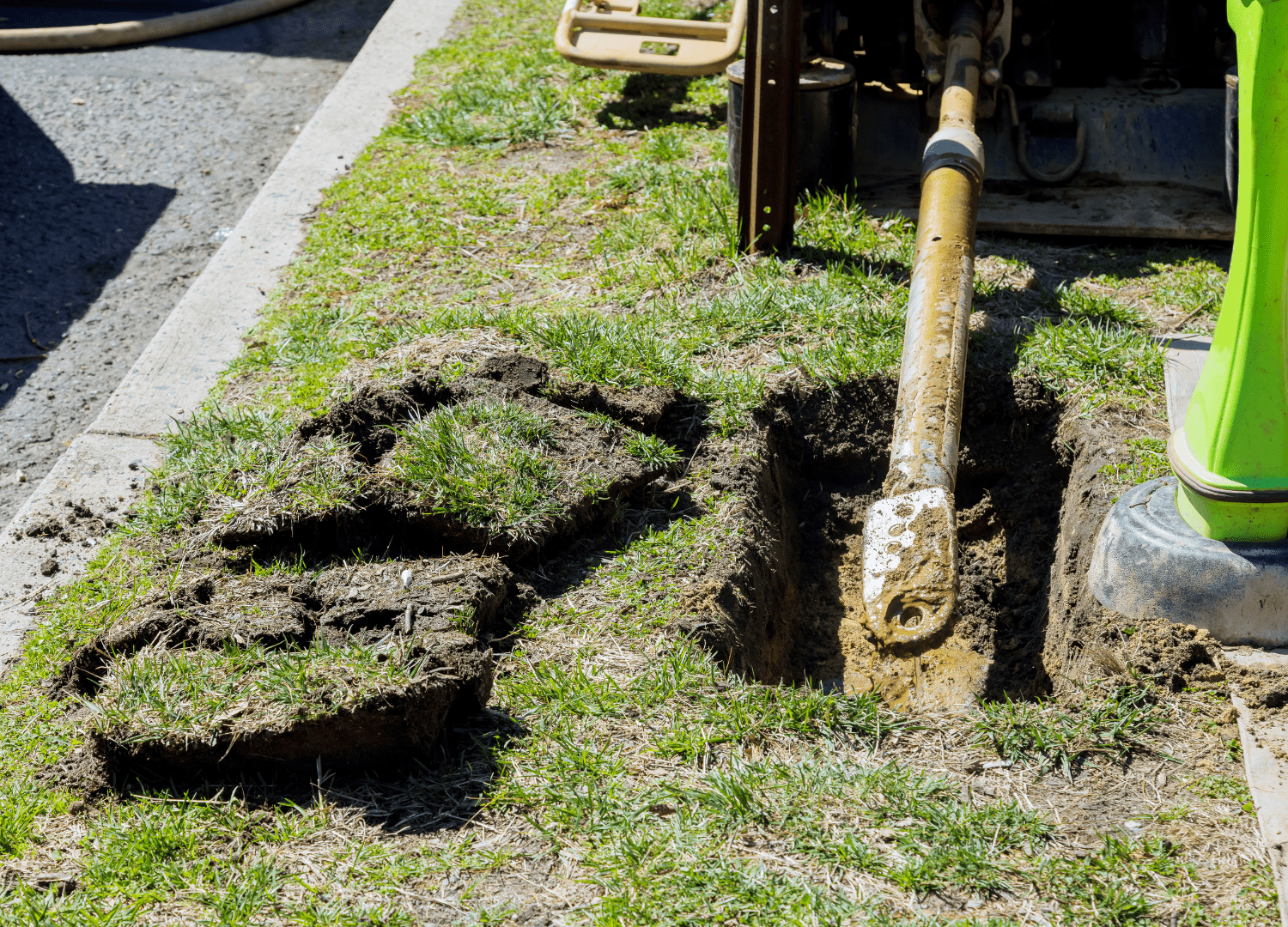

The planning and design of horizontal directional drill (HDD) paths begins with defining the obstacles to be crossed. An HDD project can be a major event, such as a significant water crossing, or a relatively minor project, such as crossing driveways or roads. Regardless of the nature of an HDD project, identifying potential risks and problems is key for project planning and execution. Effective project planning and execution strategies rely on extensive surface and subsurface investigations. These investigations assist the owner in the planning, design, and execution of the project.

Key Factors in HDD Project Planning

The planning effort and execution strategies for an HDD project are affected by many factors such as site conditions, soil formations, terrain, existing utilities, and equipment set-up restraints. Even with the best planning efforts, the execution of the project can vary from the plan and the final bore path may change from the original design. This is usually the result of the actual drilling conditions being different than what was expected based on the subsurface investigation. It is important that during the planning stage, alternate scenarios are identified and planned for in the event of the unexpected. We all know that even the best plans fail when based on faulty data or poor assumptions. It is critical for project success that the HDD plan is technically feasible. Can a qualified contractor execute this HDD with existing equipment, tools, and techniques.

Conducting a Comprehensive Site Characterization

There are many factors to consider when evaluating the technical feasibility of an HDD project. Conducting a site survey is important for all HDD projects and is a significant part of the HDD site characterization. The site survey should include surface and subsurface investigations. Successful HDD projects are based on a design that is tailored to the site and the anticipated subsurface conditions. Experience has taught us that a thorough site investigation prior to project design and construction is the most effective means of managing project risks.

Addressing Geotechnical Limitations

Many HDD Projects are attempted with little consideration to the actual site conditions and limited understanding of how the conditions may impact the HDD installation. This often results in:

- Poor drill paths

- Poor selection of drill tools

- Poor drill fluid design

- Equipment loss

- Changed conditions claims

- Costs overruns

- Project failure

Selecting the Optimal HDD Crossing Location

The purpose of the site characterization is to identify and avoid potential problems; assess the risk associated with the site conditions, and ensure the project is properly designed. The main goals of the site characterization are typically:

- Topographic survey of the pipe alignment.

- Identifying and locating features in the vicinity of the drill path.

- Identifying the surface and subsurface conditions.

- Determine geology of soil between the drill path and surface.

- Develop a detailed analysis of the surface and subsurface conditions.

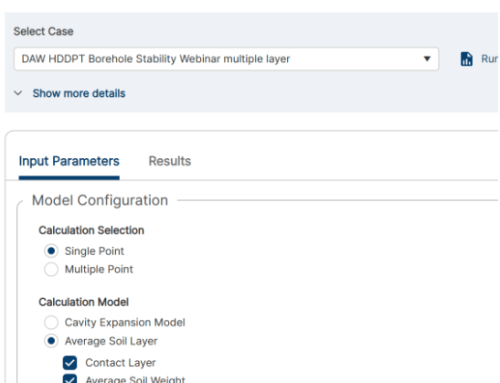

During the planning phase, analyzing the effectiveness of HDD methods in the anticipated subsurface conditions is critical to project success. The nature of the soil and bedrock materials is one of the primary geotechnical limitations to the installation of a pipeline using an HDD. A high proportion of coarse-grained materials (e.g., gravel, cobbles and boulders) as well as excessive bedrock strength and hardness are the main subsurface characteristics that may impair the use of HDD. Coarse-grained soils are not readily fluidized by drilling muds and can present a serious constraint to the feasibility of an HDD. Boulders or clusters of cobbles that remain in the drilled path can be an obstacle to the bit, reamer as well as the pipeline. Excessively hard rock makes all phases of the HDD difficult. Extensive fracturing or jointed rock can present problems like those encountered with coarse granular deposits. Competent rock with an unconfined compressive strength of approximately 60,000 psi can be negotiated with an HDD, given today’s technology. One problem often encountered when facing such characteristics at depth is the tendency of the drilling string to deflect rather than penetrate the subsurface.

Balancing Considerations for HDD Method Selection

Selecting the preferred HDD crossing location should consider the pipeline alignment and access for HDD construction equipment. The crossing location should allow for layout areas, entry/exit pads, access routes and the pipe string layout area. The crossing location should allow flexibility in using various crossing methods, especially if the HDD fails and an alternative crossing technique is required; flexibility to use various accesses or vehicle crossing methods; and flexibility in refining the exact crossing location if constraints prevent certain alignments.

When deciding which HDD technique is the best method for a pipeline crossing, many factors must be considered. The primary factors include pipeline diameter; project schedule; definition of obstacle(s) such as crossing width and depth; environmental sensitivity and associated constraints; geotechnical concerns; costs of the various alternatives; amount of working space; regulatory requirements and conditions including timing constraints; landowner and community issues; engineering constraints; and construction season.

The selection of a crossing method is an exercise in striking a balance among the previously discussed considerations to decide the most practical solution. The preferred method is usually that which is technically feasible and offers the required level of environmental protection for the lowest cost. Selection of an HDD crossing when other methods are more cost effective, technically feasible and offer sufficient environmental protection may be inappropriate. If an HDD is the preferred method by regulators and this method is considered to have a low likelihood of success or is otherwise impractical, the regulators should be provided detailed information on the crossing method selection process and the rationale for the rejection of the HDD method.

More on HDD Techniques

For more information regarding this blog topic, read our Soil Type Impact in HDD blog or join me in my self paced training on Advanced HDD for Pipelines. You can also contact me, the author, David Willoughby, at [email protected]

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]