Applications of RSTRENG Software For Corrosion and Metal Loss Assessment

by: Adam Schindewolf

What Are RSTRENG and ASME B31G Calculations?

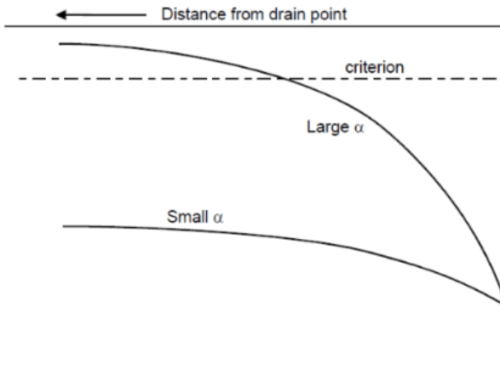

ASME B31.G Original and ASME B31.G Modified are Level 1 calculations used to assess corroded pipelines for removal, repair, or continued operation provided the metal loss was calculated to fall within safety limits. While the B31G criterion helped operators avoid many unnecessary pipe cutouts, there was a concern that the criterion was too conservative and led to cut outs that may not have compromised the safety of the pipeline. Thus, the modified B31.G method was adopted in the ANSI/ASME B31 code. A key difference between the two is the fact that ASME B31.G Original represents the entire effective area with a single parabola using a 2 term folias factor, while B31.G Modified represents the entire effective area with a modified rectangle using a 3 term folias factor. They each use two measurements: maximum depth and length. For hand calculations, a factor of 0.85 was recommended for the modified criterion, rather than the initial 0.67 in the original ASME B31G.

Then, an effective area method was developed using the measured profile of the corroded area, providing more accurate predictions. This effective area method was called RSTRENG. RSTRENG is a level 2 calculation that requires more data and more intensive calculations. It is sanctioned by DOT CFR 49, 192, and 195 to calculate the remaining strength along extended length of metal loss of the pipe. It is the most accurate method to perform remaining strength calculations and has been approved by PHMSA. It calculates failure, safe operating pressure, and factor of safety based on the extent of metal loss.

How is RSTRENG used?

There are several problems that engineering teams face that RSTRENG can help to address:

Problems

- Sections of pipe need to be prioritized for investigation

- Investigating and repairing or removing pipe require expensive materials and extensive labor

- An optimal approach for repairs needs to be determined

- Excessive repairs introduce the risk for collateral damage

- The effects of metal loss need to be factored into pipeline operations

RSTRENG as a Solution

- Used to determine reassessment intervals

- Used to determine remaining life and metal loss

- Used as part of an Engineering Critical Assessment

- Used to verify and optimize in-line inspection

Applying the RSTRENG Software Solution

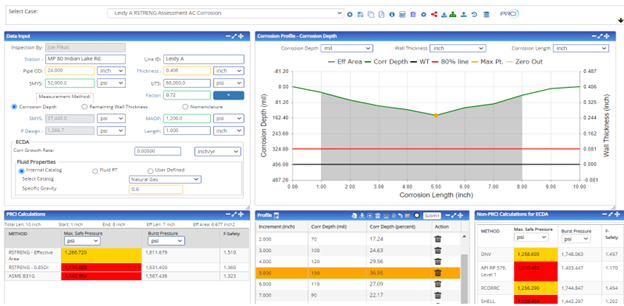

While the RSTRENG calculation provided a strong basis for understanding the remaining strength of a pipe and making determinations regarding removal, repairs, and continued operation, it became apparent that engineering teams could gain even more value through data visualization, automation of the RSTRENG method across all effective lengths, the inclusions of ASME B31.G Original and Modified calculations for comparison, and a variety of alternate calculations including DNV, API RP 579 Level 1, PCORRC, and Shell. In addition, these calculations can be extrapolated upon to provide:

- Failure Pressure Ratio

- Time Until Failure

- Remaining Life

- Re-assessment Intervals

- Potential Impact Radius

Suddenly, the utility of these calculations is much more readily apparent. Understanding these elements of a corroded pipe segment are crucial to determining an effective integrity management plan. Without a solid understanding of these factors, the cost associated with investigative digs can quickly snowball out of control resulting in monumental costs and introducing the risk of damage to the pipe during excavation . Through these calculations, engineering teams are able to optimize investigative digs, reassessment intervals, and other key elements to a comprehensive integrity management plan.

For more information regarding this blog topic, please visit the Technical Toolboxes Youtube channel, where you may watch a recording of PRCI and Technical Toolboxes’ joint webinar that covers this topic in more detail.

FOR MORE INFORMATION:

[email protected]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]

Corrosion Engineers: How Confident Are You in Your Remaining Strength Calculations?

Corrosion Engineers: How Confident Are You in Your Remaining Strength Calculations? By Kesley Price [...]

Why API Inspections Still Matter More Than Ever

Why API Inspections Still Matter More Than Ever By Kesley Price In an industry [...]