Pipeline Pressure Testing: Protocols and Procedures

By Febin Jose

Pipeline pressure testing is a critical component of pipeline engineering, ensuring structural integrity and operational safety. With the increasing complexity of pipeline networks, understanding the protocols and procedures for pressure testing has never been more crucial. In this blog, we explore the intricacies of pipeline pressure testing, the challenges it addresses, and how innovative tools like the Hydrotest PowerTool enhance the process.

Understanding Pipeline Pressure Testing

Pipeline pressure testing, commonly referred to as hydrostatic testing, serves as the gold standard for verifying the strength and integrity of pipelines. It is conducted in both new constructions and existing pipelines to:

- Validate the structural integrity of new pipelines.

- Recertify Maximum Allowable Operating Pressure (MAOP) for aging infrastructure.

- Identify and diagnose defects caused by accidents or wear.

In this process, a pipeline section is filled with water and pressurized beyond its normal operating levels. The pressure is maintained and monitored for fluctuations, which may indicate leaks or weaknesses in the pipeline structure.

Challenges in Hydrostatic Testing

Despite its effectiveness, hydrostatic testing is not without challenges:

- Operational Downtime: For existing pipelines, sections must be taken out of service, which can impact supply.

- Resource Management: Planning water sourcing and disposal, as well as managing personnel and equipment, requires meticulous coordination.

- Compliance Complexity: Ensuring alignment with regulations such as the MEGA Rule and maintaining traceable, verifiable, and complete (TVC) records can be daunting.

Hydrotest PowerTool Advantages

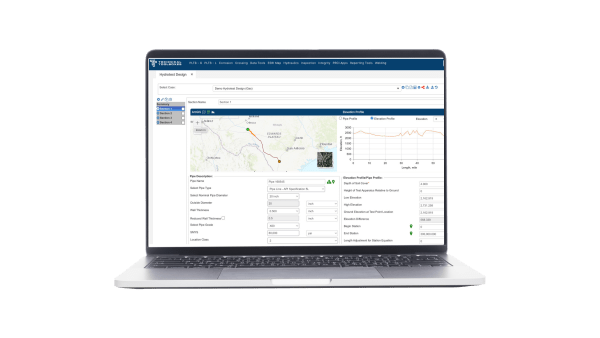

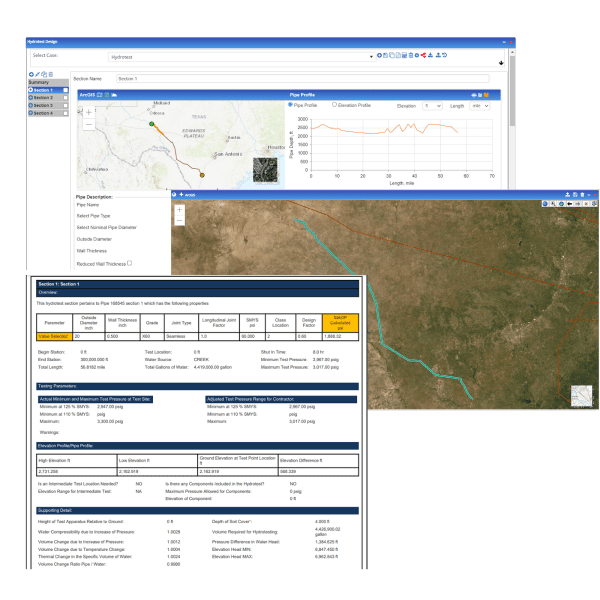

The Hydrotest PowerTool from Technical Toolboxes addresses these challenges with a suite of advanced features designed to streamline hydrostatic testing:

- Semi-Automated Planning: Reduces planning complexity by allowing users to segment pipelines based on elevation, class location changes, and water availability.

- Comprehensive Record-Keeping: Ensures compliance with TVC requirements, minimizing regulatory risks.

- Data Integration: Leverages GIS mapping and the Pipeline HUB to centralize data, eliminating repetitive inputs and reducing errors.

- Actionable Insights: Diagnoses defects and generates field-ready project plans to optimize execution.

By integrating these features, the Hydrotest PowerTool significantly enhances test efficiency while reducing both capital and operational expenditures.

Hydrotest Planning and Execution: A Step-by-Step Guide

1. Pre-Test Preparation:

- Segment the pipeline for testing based on critical criteria like elevation head and class location changes.

- Install test heads and fill the section with water.

2. Pressurization:

- Increase pressure to the desired test levels and monitor for at least eight hours.

- Identify any fluctuations that may indicate leaks.

3. Post-Test Procedures:

- Replace defective sections if required, retest, and reconnect the pipeline.

Advanced tools like the Hydrotest PowerTool simplify these steps by automating much of the planning and analysis, allowing engineers to focus on decision-making and execution.

Innovations in Pipeline Testing

Innovative solutions like the Hydrotest PowerTool represent the future of pipeline pressure testing. By integrating advanced GIS capabilities, automated workflows, and real-time diagnostics, these tools not only enhance efficiency but also bolster compliance and safety standards. This innovation ensures that pipeline operators can meet growing industry demands while maintaining the highest levels of integrity.

Pressure Testing with Hydrotest PowerTool: A Game-Changer

For pipeline operators looking to overcome the challenges of hydrostatic testing, the Hydrotest PowerTool offers unparalleled advantages. Its ability to automate critical processes, ensure regulatory compliance, and provide actionable insights makes it an essential tool in modern pipeline engineering.

Ready to take your pipeline testing to the next level? Discover how the Hydrotest PowerTool can transform your testing processes and optimize your operations.

Want to learn more?

Visit our Hydrotest PowerTool page or schedule a demo today!

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]