What You’re Getting with Hot Tap

Safety and Efficiency

Safety and Efficiency

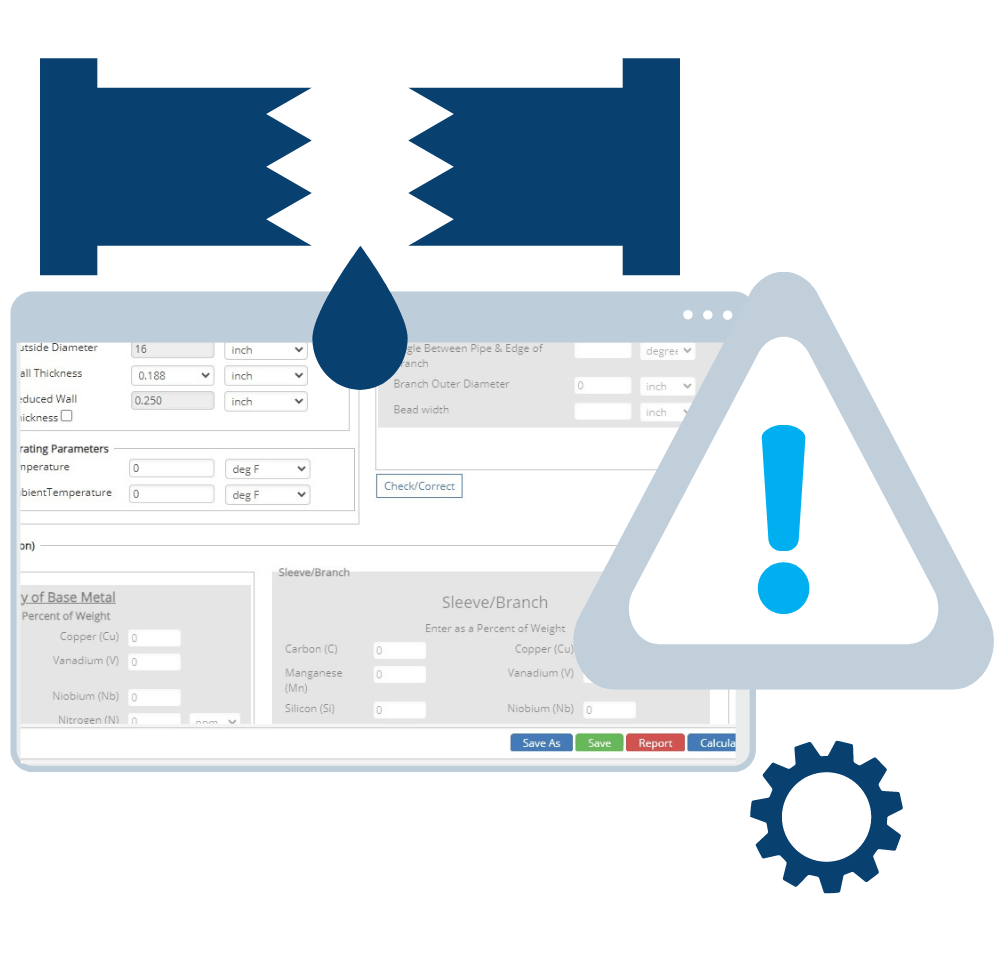

Manage Heat Input & Cooling for Safer In-Service Welding

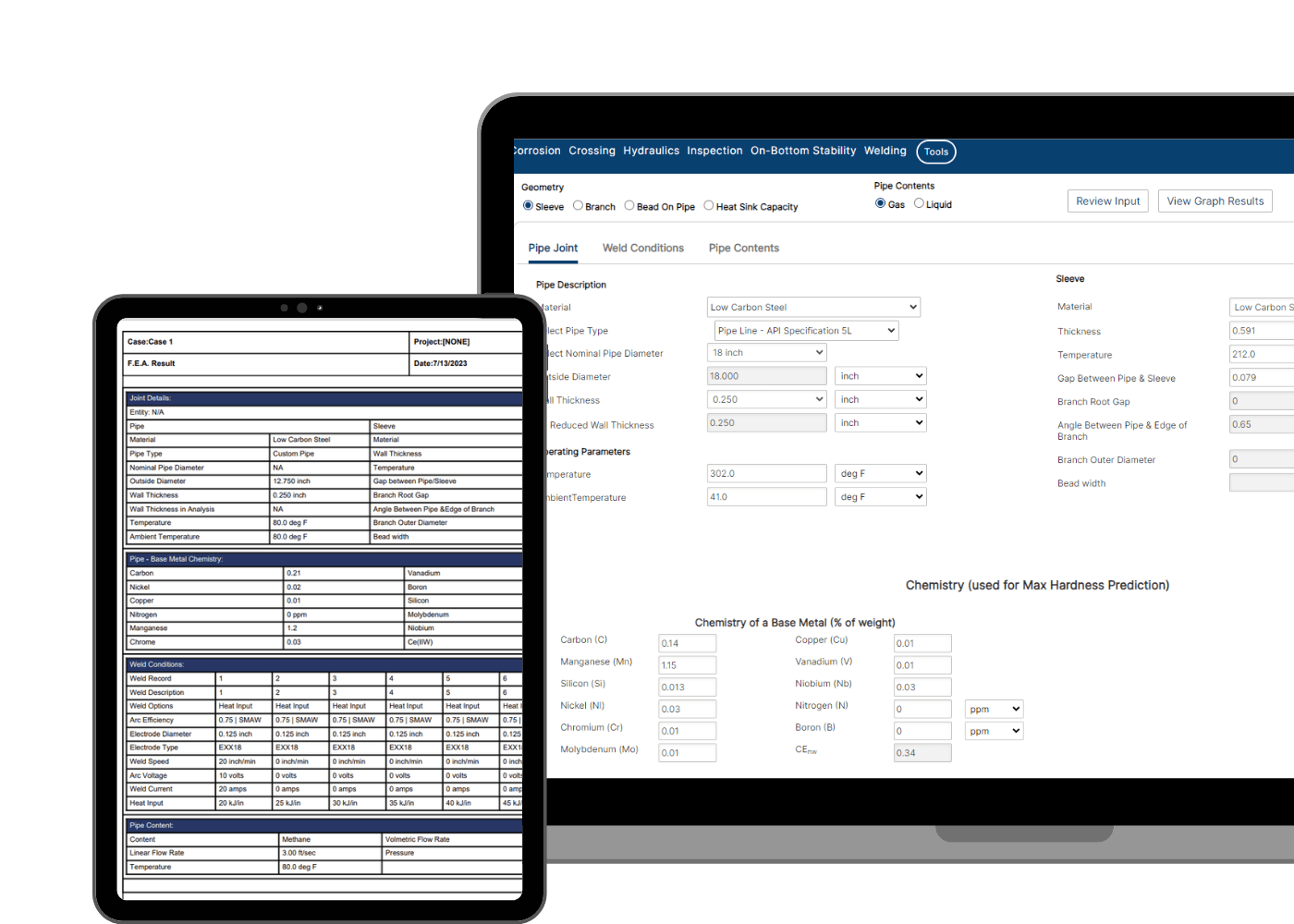

Detailed Analysis

Detailed Analysis

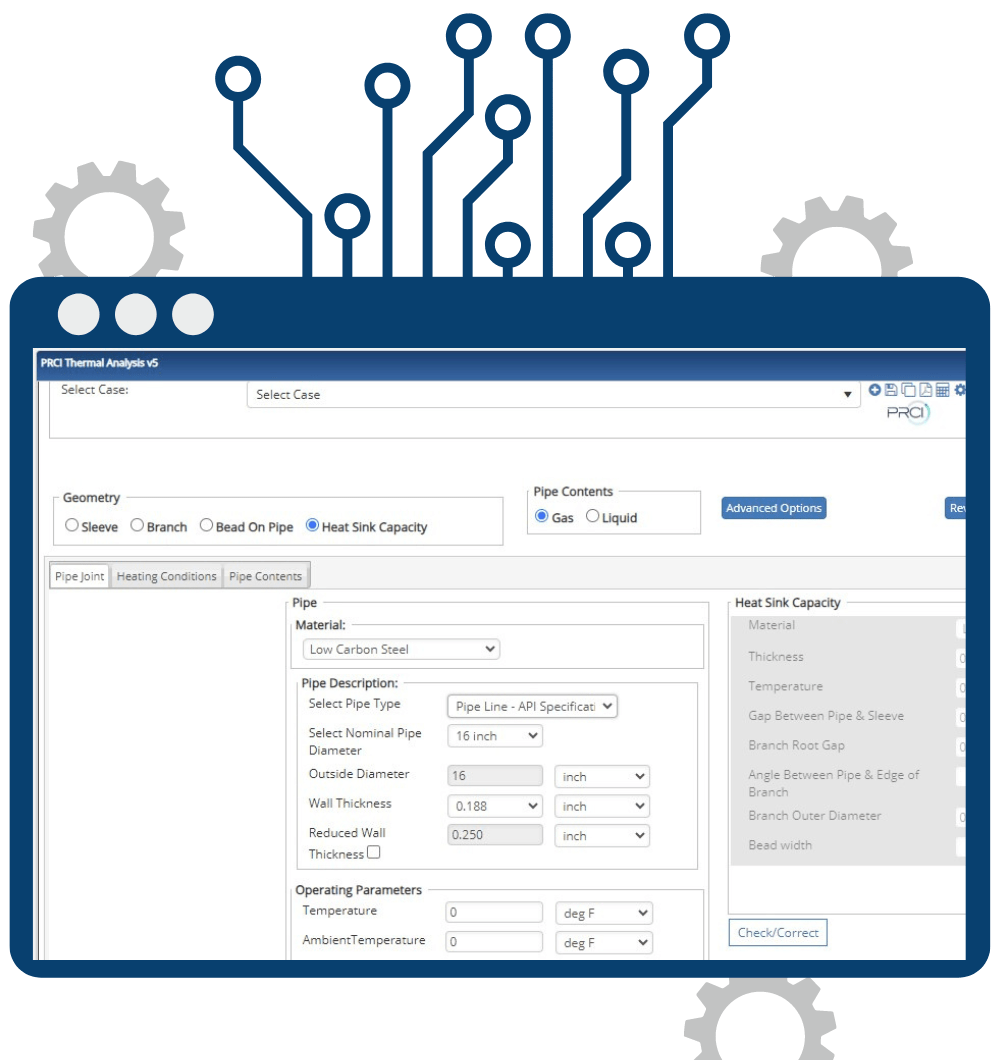

Accurate Heat Sink Capacity for Welding Attachments

Better Hot Tap Data, Faster

Better Hot Tap Data, Faster

Safely Accelerate Project Evaluation

Full Industry Compliance

Full Industry Compliance

Hot Tap Standards at Your Fingertips