Technical Toolboxes’ Asset Management Database: Streamlined Asset Tracking for Industrial Facilities

By Jeff Walling

![]()

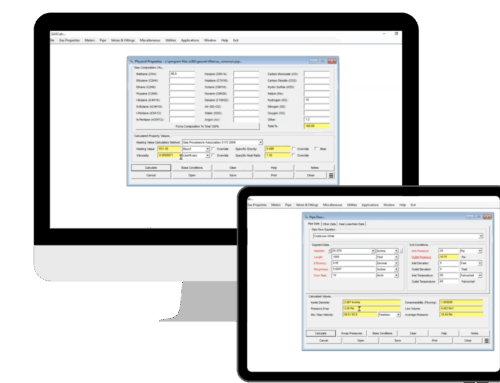

The Technical Toolboxes’ Asset Management Database (AMDB) is designed with the unique needs of small to mid-sized industrial facilities—such as power plants, chemical plants, and tank farms—in mind. Our user-friendly software simplifies the tracking of assets by allowing facility owners and inspection teams to easily input data following each inspection.

Unlike larger, more complex tracking systems that require exhaustive entry of all thickness measurement (UT) data points—often numbering in the thousands—our AMDB focuses on critical inspection intervals determined by the governing corrosion rates of each vessel. This approach eliminates the cumbersome process of tracking every single data point while still ensuring comprehensive asset management.

Key benefits of our AMDB include:

- Efficient Data Management: Users are not burdened with the need to enter and maintain extensive measurement data. Instead, they input only the relevant inspection intervals, streamlining the process.

- Holistic Evaluations: By relying on the expertise of qualified inspectors and engineers, our software supports a comprehensive assessment of equipment rather than depending solely on automated evaluations. This leads to more informed decisions regarding inspection intervals and the remaining life of assets.

- Focused Inspection Scheduling: Many large databases can become fixated on individual thickness measurement points, leading to unnecessary and frequent inspections. Our AMDB mitigates this issue by tracking only the governing results, ensuring that inspection schedules are rational and based on sound principles.

- User-Friendly Interface: With straightforward input methods, the AMDB makes it easy for users to manage and update their inspection programs without the time-consuming upkeep associated with more cumbersome systems.

Efficient Asset Management

In summary, the Technical Toolboxes’ Asset Management Database empowers small to mid-sized industrial facilities to maintain an effective, efficient, and user-friendly asset management program. With intelligent scheduling and qualified oversight, our solution ensures that every piece of equipment is evaluated accurately and effectively.

Items Tracked by the API TB Asset Management Database (AMDB)

The API Technical Toolboxes’ Asset Management Database (AMDB) provides comprehensive tracking for a variety of industrial equipment, ensuring that inspection intervals and critical documentation are efficiently managed. Below is an overview of the key items tracked:

Equipment Tracking:

- 1. Pressure Vessels (PVs)

-

- Inspection Intervals: Internal, external, ultrasonic (UT), eddy current, and state inspections.

- 2. Aboveground Storage Tanks (ASTs)

-

- Inspection Intervals: Internal, external, and UT inspections.

- 3. Relief Valves (RV/PSVs)

-

- Inspection Intervals: Recertification schedules.

- 4. Piping

-

- Inspection Intervals: Internal, external, and UT inspections.

- 5. Pumps

-

- Tracking: Life cycles and preventative maintenance (PM).

- 6. Motorized Operating Valves (MOVs)

-

- Tracking: Life cycles and preventative maintenance (PM).

- 7. Custom Tracking

-

- The system can be tailored to include any additional items the user wishes to monitor.

Documentation and Data Management:

- Engineering Document Storage

-

- Design specifications, design drawings, P&IDs, and MSDS in electronic formats (Word, AutoCAD, PDF).

- Inspection Reports

-

- Comprehensive documentation of internal, external, and non-destructive testing (NDE) results, available as electronic files (Word, AutoCAD, PDF).

- Equipment Static Data

-

- Essential records to meet Process Safety Management (PSM) requirements.

- Inspection Intervals

-

- Based on inspection results, API recommendations, and risk-based inspection (RBI) plans.

- RBI Planning

-

- Risk assessments considering consequence and probability, utilizing a risk matrix derived from RBI evaluations.

- Action Items

-

- Includes work orders, repair notes, and engineering assessments to facilitate timely responses to identified issues.

The API TB Asset Management Database (AMDB) is designed to streamline asset management and enhance operational efficiency, providing users with a robust tool for tracking and managing critical inspections and documentation.

Watch Full API Toolbox AMDB Demo

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]