The API Inspector’s Digital Revolution:

Maximize Field Time, Cut Report Delays, and Prove Return on Investment (ROI) with API Toolbox

By Jeff Walling

Rethinking How We Do API Inspections

The pace of work in oil, gas, and chemical facilities doesn’t slow down for paperwork. Yet for many API inspectors, that’s exactly what happens after the fieldwork is done.

You spend hours collecting data on pressure vessels, piping, or tanks. But instead of moving on to the next job, you’re stuck back at your desk—navigating spreadsheets, formatting PDFs, chasing reference codes, and stitching it all together into a 50-page report.

That lag between inspection and report delivery isn’t just frustrating. It introduces risk, limits your capacity, and increases the chance of errors.

So why are we still working this way, when the possibilities with API Inspection Software are out there?

Why Legacy Inspection Methods Fall Short

Let’s look at the typical API inspection workflow:

- Calculations handled in Excel

- Photos and drawings imported from Paint or AutoCAD

- Reports written in Word, exported to PDF

- Inspection data stored in local folders—or worse, someone’s memory

This patchwork approach creates more than just delays. It opens the door to:

- Manual input errors that compromise compliance

- Scattered records that are difficult to audit

- Missed inspection timelines or data inconsistencies

For third-party inspectors and asset owners alike, these issues compound over time and scale.

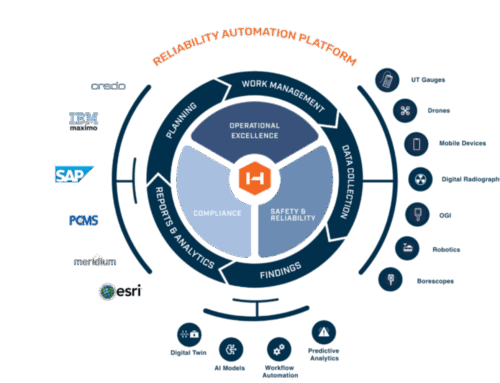

A Shift Toward Centralization and Automation

Today’s inspection landscape is evolving under increasing regulatory pressure, including the Pipeline and Hazardous Materials Safety Administration (PHMSA) Mega Rule and a renewed focus on TVC (Traceable, Verifiable, and Complete) documentation.

To adapt, many are turning to integrated platforms like API Toolbox. Not because it’s the trendy thing to do, but because workflows that used to be “good enough” no longer meet the demands of fieldwork and audits.

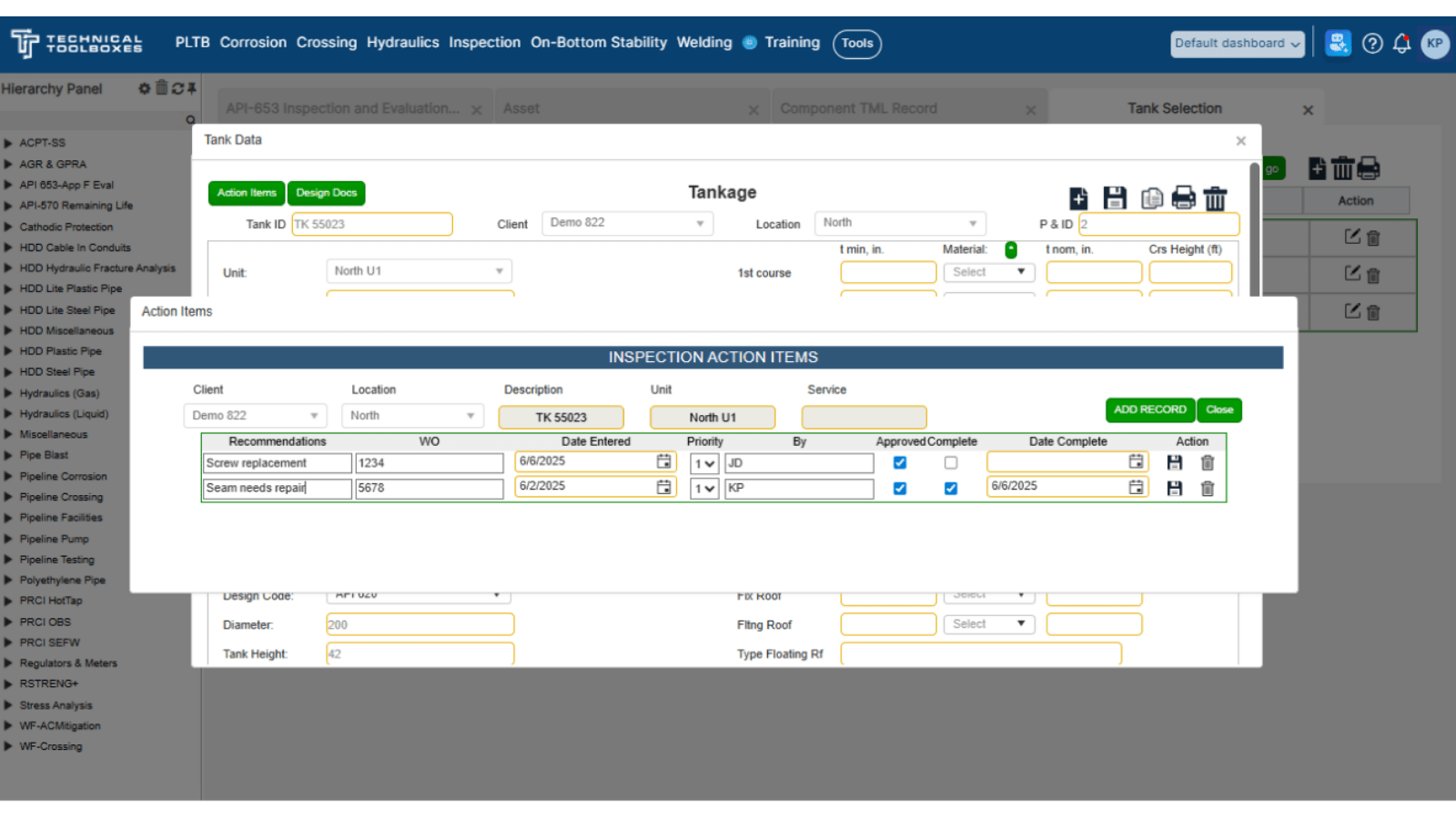

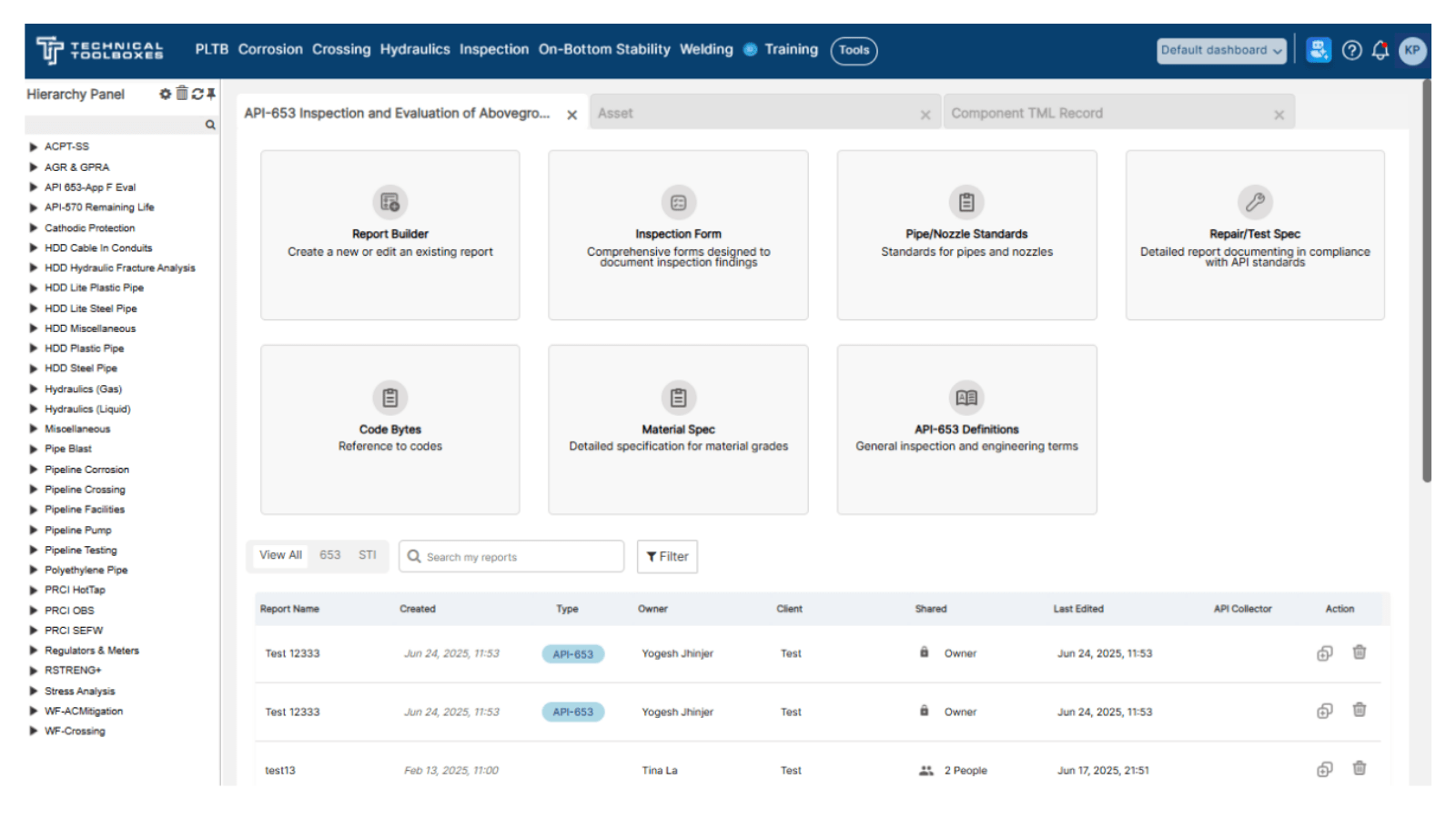

Here’s the core idea: Instead of juggling five tools, inspectors can now use one system that’s purpose-built for API 510, 570, and 653 inspections, engineering calculations for all component evaluations, and asset management (including inspection intervals & action item tracking).

That’s not just a convenience, it’s a structural shift in how inspections are documented, reviewed, and shared.

What a Centralized Approach Looks Like in Practice

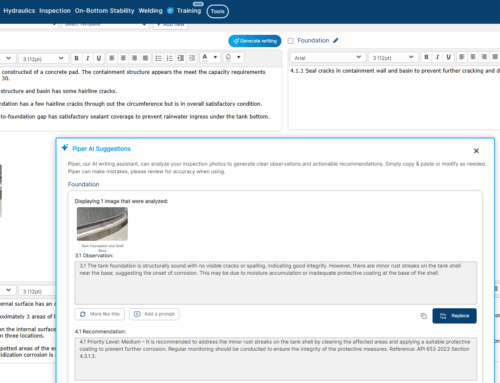

At its core, the API Toolbox is a platform that brings everything under one roof. From inspection templates to asset records, it aims to remove repetitive data entry and reduce friction in the report-building process.

What’s inside the platform:

- Prebuilt templates for API 510, 570, and 653

- Built-in code references and engineering calcs

- A centralized asset management database (AMDB) for organizing and updating equipment information

- A mobile Collector App for syncing field data directly into reports—even offline

The key benefit here isn’t the software—it’s the workflow transformation. Inspectors spend less time formatting and more time doing the work they’re trained for.

How Time Savings Translates Into ROI (Without the Sales Pitch)

Let’s pause to address a concern: ROI often sounds like a sales buzzword. But for inspectors and managers, time is the most measurable—and most limited—resource.

Here’s a real-world example:

- An inspector charges $100/hr

- They complete 5 reports per week

- Each report takes 10 hours longer without integration

- That’s 2,400 hours a year—or $240,000 in opportunity cost

When tools reduce that time, it doesn’t just save money. It opens up capacity. That might mean taking on more projects, meeting deadlines more easily, or finally getting ahead of documentation instead of constantly reacting to it.

Asset Owners and Operators: What’s at Stake?

While API Toolbox is often discussed in the context of third-party inspection teams, operators have just as much to gain.

For owners and operators managing large portfolios of assets, the challenges are different, but related:

- How do you know an inspection happened on time?

- Can you locate the last inspection data on a given tank or line segment?

- Are your records TVC-compliant and audit-ready?

An organized, searchable system with standardized reporting helps solve these issues, especially when that system supports inspection data, asset history, and regulatory documentation in a single place.

What PHMSA’s Mega Rule Changed (And Why It Matters)

Before 2021, documentation practices varied widely. Many facilities relied on tribal knowledge and handwritten inspection notes. That changed when PHMSA’s Mega Rule brought a new level of rigor to pipeline safety.

Among the key updates:

- Stricter requirements for Maximum Allowable Operating Pressure (MAOP) reconfirmation

- Greater emphasis on material verification

- Mandatory digital audit trails

If your inspection records can’t be traced, verified, and completed using consistent methods, you’re at risk of noncompliance. More importantly, your asset decisions may be based on outdated or incomplete data.

Tools like API Toolbox don’t eliminate this responsibility, but they make it a lot more manageable for API 510, 570, and 653 inspections.

Field Feedback: What Are They Saying

This shift in process isn’t theoretical. Inspectors and Operators using modern digital tools inspection report meaningful changes in their day-to-day work.

“Since the acquisition of the Technical Toolboxes API 510/570 modules, we can now calculate the minimum thickness per the respective codes in advance. The field NDE technician can reference these thicknesses in the field as a trigger point to alert the subject matter experts. Corrective action can be taken to repair any deficiencies, therefore providing a proactive approach to inspections.” – Mechanical Integrity Engineer, Midstream Operator

“I like the customizable Report Builder, the ability to tailor the verbiage, and the comprehensive appendices in the API Toolbox. I also find the tool simple to use.” – Inspector, AST Inspection Company

“The Asset Manager allows us to share Key Performance Indicators (KPI) with our upper management. This module also helps us maintain regulatory compliance to ensure that we do not have any outstanding inspections.” – Mechanical Integrity Engineer, Midstream Operator

Want to Modernize Your API Inspections?

Whether you’re an independent contractor trying to improve throughput or a facility manager aiming to strengthen your audit trail, the message is the same:

Digital inspections are no longer a luxury; they have become the new standard.

That doesn’t mean abandoning your expertise or the way you like to work. It means using tools that support the standards you already follow, without the administrative overload.

If your team still relies on Word templates, folders of PDFs, or “version_final_final3.docx,” it might be time to rethink your approach.

Final Thought: This Isn’t About Software. It’s About Better Workflows.

Technology is only helpful if it fits into your world without adding complexity. API Toolbox isn’t perfect for everyone, but for teams doing API 510, 570, or 653 inspections, it reflects the realities of the job.

- Field-first, not office-first

- Code-informed, not code-burdened

- Collaborative, not siloed

- Automated process, not manual

And most importantly: Built by inspectors, not just for them.

Interested in exploring further?

You don’t need to commit to anything. Start by mapping your current process. Where do delays happen? What errors repeat? How long does an inspection report really take?

That’s the first step toward deciding whether it’s time for a change.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]