The Colebrook-White Equation Demystified

By Febin Jose

The Colebrook-White equation is a fundamental tool used in fluid dynamics, particularly in pipeline engineering, to estimate the friction factor for turbulent flow in a pipe. Despite its importance, the equation’s complexity often intimidates engineers and students alike. This blog aims to break down the Colebrook-White calculations into simpler terms, showing its practical application and relevance in pipeline hydraulics.

What Is the Colebrook-White Equation?

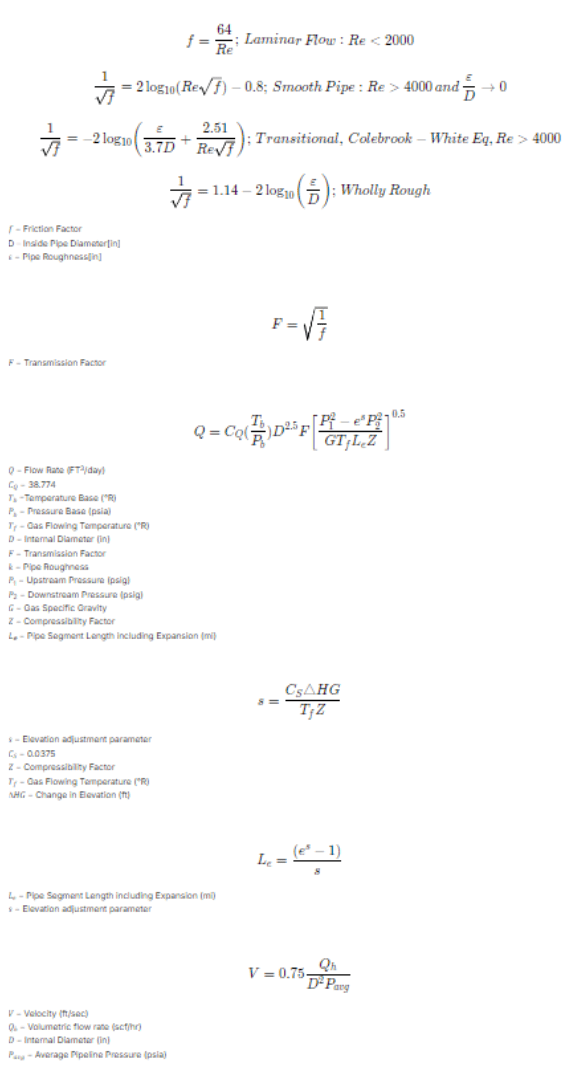

The Colebrook-White equation is used to calculate the Darcy-Weisbach friction factor (f), which is critical in determining pressure loss in pipelines due to friction. It combines factors such as the Reynolds number and the relative roughness of the pipe’s surface, both of which influence flow behavior.

The equation is expressed as:

Why Is It Important?

In hydraulic calculations for pipelines, the friction factor is necessary to determine the energy loss due to friction between the fluid and the pipe walls. This frictional energy loss translates to pressure drop, which must be accounted for in the design and operation of pipelines. As a result, this equation is invaluable in ensuring that pipelines operate efficiently and safely.

Simplifying the Equation

The Colebrook-White equation is implicit, meaning it cannot be solved directly for f. However, modern software, including Technical Toolboxes’ Pipeline Toolbox (PLTB), simplifies this process, automating the calculation and reducing manual work. This allows engineers to focus on more complex decision-making without getting bogged down by iterative calculations.

Practical Applications in Pipeline Engineering

- Gas and Liquid Pipeline Hydraulics

In the context of pipeline engineering, this equation is crucial for calculating the pressure drop in both gas and liquid pipelines. Whether it’s transporting natural gas or crude oil, the friction factor helps engineers design pipelines that can maintain optimal flow rates while minimizing energy loss. Software like Pipeline Toolbox automates these hydraulic calculations, integrating the Colebrook-White equation into larger workflows that assess upstream and downstream pressures, flow rates, and volumes. This ensures safe and efficient pipeline operations. - Friction Factor Calculations

Friction factor calculations are especially relevant when pipelines traverse long distances or handle fluids with varying viscosities. The Colebrook-White calculation becomes a key part of determining whether a pipeline’s design can support the intended operational pressures. For example, Technical Toolboxes’ suite of tools, including the PLTB, automates these calculations and ensures compliance with industry regulations, such as those set by PHMSA and ASME.

Colebrook-White in Action: Hydraulics and the Pipeline Toolbox (PLTB)

Technical Toolboxes’ Pipeline Toolbox (PLTB) integrates over 250 calculations, including friction factor calculations based on the Colebrook-White equation. By using smart automation and data integration features, PLTB reduces manual input errors, streamlines workflows, and ensures precise hydraulic analysis.

Key features include:

- Hydraulic calculations for gas and liquid pipelines: These tools allow engineers to assess upstream and downstream pressures and volumes, ensuring pipelines operate within safe parameters.

- Friction factor estimations: The PLTB simplifies the process of determining friction factors by incorporating the Colebrook-White equation into its workflow, automating the iterative process of solving the equation.

Conclusion

The Colebrook-White equation, while complex, is an essential tool in pipeline engineering, particularly for calculating pressure losses in turbulent flow. By integrating this equation into modern software solutions like Pipeline Toolbox, engineers can simplify complex hydraulic calculations, ensuring pipelines operate efficiently and safely.

As pipelines continue to expand globally, the importance of accurate friction factor calculations will only grow, making the Colebrook-White equation a staple in every pipeline engineer’s toolkit.

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]