Understanding Limitations for HDD

By David Willoughby

Preferred Crossing Method

Horizontal directional drilling (HDD) has emerged as a preferred crossing method in many situations for the installation of oil and gas pipelines as well as other utilities under watercourses, roads, rail lines, steep slopes, and other obstacles. This technology has been enthusiastically embraced by proponents, contractors, and regulators as a potentially low-impact construction technique. In many cases, however, the suitability of the HDD method must be evaluated and compared to open-trench construction techniques and other trenchless construction techniques to ensure that an appropriate technique is chosen for the conditions and concerns present at a particular crossing. Recognition of the advantages, limitations, and potential risks of HDD is an important step in this evaluation. The successful design and construction of an HDD is the result of a team effort combining the skills of the regulatory group, owner, engineering consultant, environmental consultant, inspection services, and specialist HDD contractor. An HDD may have the highest risk of failure of any activities on a project. The design of the drill path should consider all the information gathered for the crossing area. The physical limitations of the site as well as geotechnical, environmental (fish, wildlife, vegetation, land use, cultural), and hydrological information should be considered in the preparation of the HDD design. The feasibility of HDDs is dictated by the length of the borehole to be drilled, the diameter(s) of the pipe string, the surface conditions, and the subsurface conditions.

Method of Drilling

Typical classifications based on length are:

- Short HDDs: Less than 1,000 feet

- Medium HDDs: 1,000-3,000 feet

- Long HDDs: 3,000-5,000 feet

- Extremely Long HDDs: Over 5,000 feet

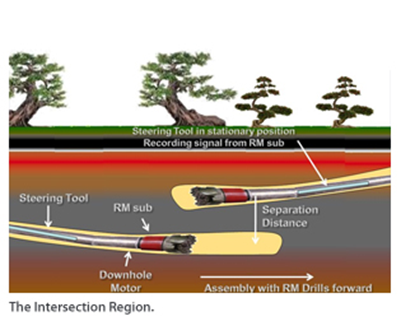

While contractors’ preferences and site conditions play a significant role, HDD’s over 6,000 feet are usually constructed with the intersect method. HDD intersects require two pilot holes, one from the entry side and the other from the exit side of a crossing. The two pilot holes are drilled towards each other, and they intersect at a predetermined point. It is often cost effective to use two drilling rigs and drill both pilot holes at the same time. Many drilling contractors have perfected intersect drilling to the point that it has become an accepted method of drilling when faced with certain difficult kinds of crossing conditions such as:

- Extended Reach Crossings

- Crossings with Pressure Relief issues

- Crossings from “Casing to Casing”

- Crossings with Steering Difficulty at Exit

Geotechnical Limitations

The nature of the subsurface soil and bedrock materials at a proposed crossing is one of the primary geotechnical limitations to the installation of a pipeline using an HDD. A high proportion of coarse-grained materials (e.g., gravel, cobbles and boulders) as well as excessive bedrock strength and hardness are the main subsurface characteristics that may impair the use of HDD.

Coarse-grained soils are not readily fluidized by drilling muds and can present a serious constraint to the feasibility of an HDD if encountered. Boulders or clusters of cobbles remain in the drilled path and present an obstacle to the bit, reamer as well as the pipeline, while excessively hard rock makes all phases of the HDD difficult.

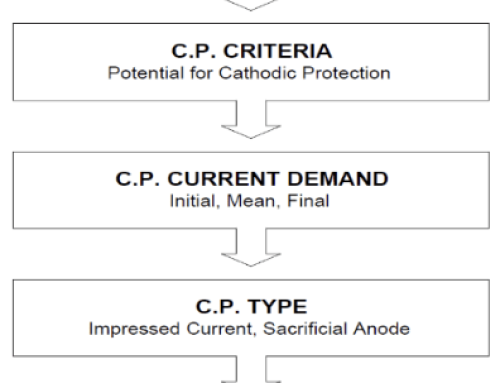

Depth of Cover

Using standard rules of thumb for minimum depth of cover for HDD construction is an outdated practice and should no longer be used. The depth of cover should be governed by the definition of the obstacle. Adequate cover should be provided to maintain crossing integrity over its design life. Depth of cover requirements is dependent upon several factors such as subsurface conditions, type of drilling equipment, mud pressure, and the difference in elevation between the entry and exit points.

The minimum depth of cover should be established by the calculations for maximum borehole pressures and a comparison of those pressures and reasonable drilling pressures. In the case where the reasonable operational drilling pressure exceeds the maximum drilling pressure, the HDD profile should be set deeper to raise the maximum drilling pressure.

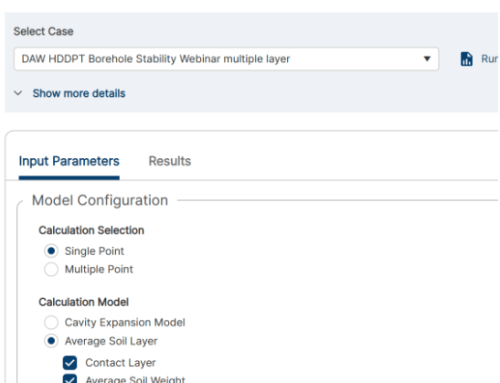

Using an HDD Design Tool

Technical Toolboxes Horizontal Directional Drilling PowerTool (HDDPT) provides a comprehensive solution to guide in the design validation, engineering, and installation phases of horizontal drilling. With HDDPT, the drilling efficiency and borehole stability can be maximized by identifying fluid characteristics and mud requirements, minimizing unnecessary costs and risks.

Using advanced industry knowledge, HDDPT allows for complex borehole design, multi-section horizontal and vertical bends, and variable entrance/exit points while also performing pull force and installation stress analyses for both polyethylene and steel pipes. HDDPT is not only designed to support both gas and liquid pipelines; it can also support the calculations for installing cables and conduits as well.

More on HDD

For more information regarding this blog topic, read our Product Pipelines Stress During HDD or join me in our HDD for Pipelines – Engineering Applications for Feasibility, Design and Stress Analysis (2-DAY) Training.

You can also contact me, the author, David Willoughby, at [email protected]

Suggested Post

The API Inspector’s Digital Revolution

The API Inspector’s Digital Revolution: Maximize Field Time, Cut Report Delays, and Prove Return [...]

Intro to AI in Midstream: What’s Here, What’s Next, and What Still Needs You

Intro to AI in Midstream:What’s Here, What’s Next, and What Still Needs You By Marc Dungler AI [...]

Horizontal Directional Drilling (HDD): Designing for Success

Horizontal Directional Drilling (HDD): Designing for Success By David Willoughby Minimize Risk and Optimize [...]