Use and Misuse of Tensile Testing to Determine Strength

By Bill Amend

Figure 2 – Tensile test specimen used to test a girth weld

Introduction

Perhaps you have been there. A confirming tensile test result for yield strength (YS) and ultimate tensile strength (UTS) from a third-party test lab does not match the test result on the manufacturer’s test report. What does this mean? Which one is wrong, or is there an alternative explanation?

There are numerous potential sources of variations in tensile test results. Some indicate anomalous testing practices, while others result from allowable variations in the details of testing procedures prescribed by a specific testing standard. Here are some considerations when trying to compare tensile test results from different sources:

-

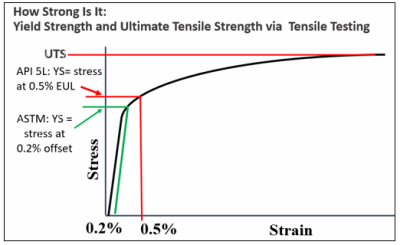

- Different testing standards include different test requirements; did the lab reference the correct standard, and the correct edition of that standard? Standards evolve over time and the current edition of the standard my have different requirements than what were in effect when the pipe or fitting was manufactured. Some standards use different definitions of “yield stress”. For example, API 5L uses a different definition than some ASTM standards. Therefore, even if a single stress strain curve is referenced, the reported Y.S. will depend upon which definition is used.

-

- Even within a single pipe, there will be some variation in properties from one end to the other and around the circumference of the pipe. Sometimes those differences can be in the range of 5- 10% of the measured value (or more).

-

- Test specimens oriented in the longitudinal direction will produce different results than specimens oriented in the transverse direction. The manufacturing standard will normally specify how the specimens are to be oriented, but it can get confusing. For example, API Standard 5L specifies that seamless pipes in a specific diameter range are to be tested in the longitudinal direction or the transverse direction, depending upon whether or not the pipes are cold expanded during manufacturing. That means you need to know the details of the manufacturing process applied to those pipes.

-

- Full-thickness transverse flattened strap specimens will produce different results than transversely oriented round bar specimens machined from unflattened straps. Flattening can reduce the yield strength because of the Bauschinger effect, and round bars machined from unflattened straps avoid the Bauschinger effect but do not sample the entire wall thickness. As a result, variations in metallurgical characteristics across the wall thickness are not entirely represented in the round bar results. For flattened straps, the details of the flattening procedure make a difference.

-

- Errors can occur during the testing procedure. For example, accidental slippage of an extensometer contact point will produce a stress-strain curve of anomalous shape, leading to inaccurate values of Y.S.. Visual examination of the stress-strain curve can often detect anomalous test results.

Ensuring Reliable Test Results

Reliable generation of tensile test data depends upon using a qualified service provider who is familiar with the applicable testing standard(s). Some testing may be done for purposes other than to show conformance to a standard. In that case, the user has a lot of options for test procedure details, and it is important to know how those details can affect results.

Conclusion

For more information regarding this blog topic, please join us in either of the following two webinars: Pipelines 101: An Introduction to the Pipeline Industry, or Pipeline Flaws and Degradation.

Or contact the author, Bill Amend, P.E. at [email protected]