Evaluation of Metal Loss Corrosion with RSTRENG

By Joe Pikas

Why Metal Loss Assessment Matters for Pipeline Safety

Corrosion is one of the most persistent threats to pipeline integrity. Metal loss assessment methods help engineers and inspectors evaluate the remaining strength of corroded pipelines, ensuring compliance with industry standards like ASME/ANSI B31G and protecting critical infrastructure from leaks or failures.

Among these tools, RSTRENG has become an industry standard for accurately assessing multiple pits and corrosion clusters, a significant upgrade from earlier single-pit evaluation methods.

From ASME B31G to RSTRENG: How Corrosion Evaluation Evolved

The original ASME B31G method (Level 1) and the Modified B31G method focused primarily on single pits, using conservative calculations to ensure safety. While these formulas, based on Battelle’s NG-18 research, were reliable, they often led to unnecessary repairs because they didn’t account for complex corrosion patterns like clusters or interacting pits.

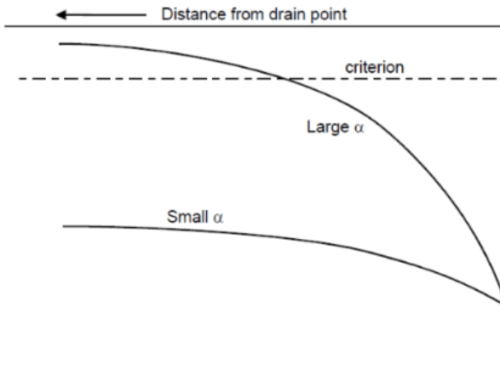

That’s where RSTRENG (Remaining Strength) comes in. Known as a Level 2 assessment, RSTRENG uses the Effective Area Method to evaluate the actual corrosion profile. By incorporating multiple, closely spaced measurements along the defect, it calculates a more accurate remaining strength and safe operating pressure, reducing unnecessary repairs without compromising safety.

Commonly Used Pipeline Corrosion Assessment Methods

Accurate metal loss evaluation is not just about compliance; it’s about maximizing asset life while maintaining safety. Pipelines in service are subject to external and internal corrosion, and U.S. DOT CFR Parts 192 and 195 mandate that operators evaluate these defects using proven, standardized methods.

Commonly used assessment methods include:

-

ASME B31G (Original Method) – Highly conservative, good for quick checks, but may lead to over-repair.

-

Modified B31G – Incorporates the Folias bulging factor and flow stress for a more balanced approach.

-

Effective Area Method (RSTRENG) – Most accurate for complex metal loss, validated by more than 200 burst tests.

-

API 579 Levels 1 & 2 – Provides additional guidelines for mechanical integrity assessments.

Other specialized methods include DNV RP-F101, PCORRC, and CORLAS, depending on pipeline type and conditions.

How the RSTRENG Effective Area Method Works

The Effective Area Method measures the precise geometry of the corrosion area, length, depth, and shape, and applies burst pressure formulas validated through extensive hydrostatic testing.

Key benefits of using RSTRENG for corrosion assessment:

-

Evaluates multiple pits and clusters, not just single defects.

-

Provides more accurate safe operating pressure calculations than conservative one-size-fits-all methods.

-

Reduces unnecessary repairs, lowering maintenance costs without reducing safety margins.

-

Integrates into pipeline integrity management software like Technical Toolboxes’ Pipeline Toolbox (PLTB) for faster, standardized workflows.

Benefits of Using RSTRENG for Complex Corrosion Profiles

Compared to B31G-based calculations, RSTRENG offers greater precision for irregular defect shapes. This means fewer false positives for replacement or repair, allowing operators to focus resources on areas of genuine concern.

Validated through extensive field testing, including over 215 burst tests, RSTRENG has proven reliable for pipelines built to industry standards, even in challenging operational conditions.

The Shift from Manual Tools to Digital Pipeline Integrity Software

In the early days of corrosion evaluation, inspectors relied on stainless steel flat pit gauges and mainframe-generated tables to calculate safe pressures. While these tools were groundbreaking at the time, they had limitations, such as ±10 mil accuracy and difficulty handling long or irregular defects.

Today, digital tools like RSTRENG integrate with GIS, asset databases, and inspection data, allowing engineers to:

-

Upload in-line inspection (ILI) data directly into the software.

-

Apply DOT-compliant assessment methods.

-

Generate TVC (Traceable, Verifiable, Complete) reports in minutes.

When to Use B31G, Modified B31G, and RSTRENG

-

Quick screening in the field: Modified B31G (Level 1)

-

High-value or complex defects: RSTRENG Effective Area Method (Level 2)

-

Advanced engineering assessment: API 579 Level 3 (finite element analysis)

Choosing the right method depends on the defect complexity, available data, and regulatory requirements.

Key Takeaways for Pipeline Operators and Inspectors

RSTRENG has proven to be a reliable, cost-effective, and technically robust method for assessing corrosion-related metal loss in pipelines. By moving beyond overly conservative methods, operators can:

-

Extend asset life

-

Maintain compliance with ASME B31G, API 579, and DOT CFR 192/195

-

Protect public safety and the environment

-

Reduce unnecessary excavation and repair costs

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]