Optimizing Pipeline Design with Weymouth and Centrifugal Compressor Calculations

By Bryant Jerome

In pipeline engineering, the optimization of design and operational efficiency hinges on precise calculations and thorough understanding of various factors that affect gas flow and pressure. Among these critical calculations, the Weymouth equation and centrifugal compressor calculations play pivotal roles.

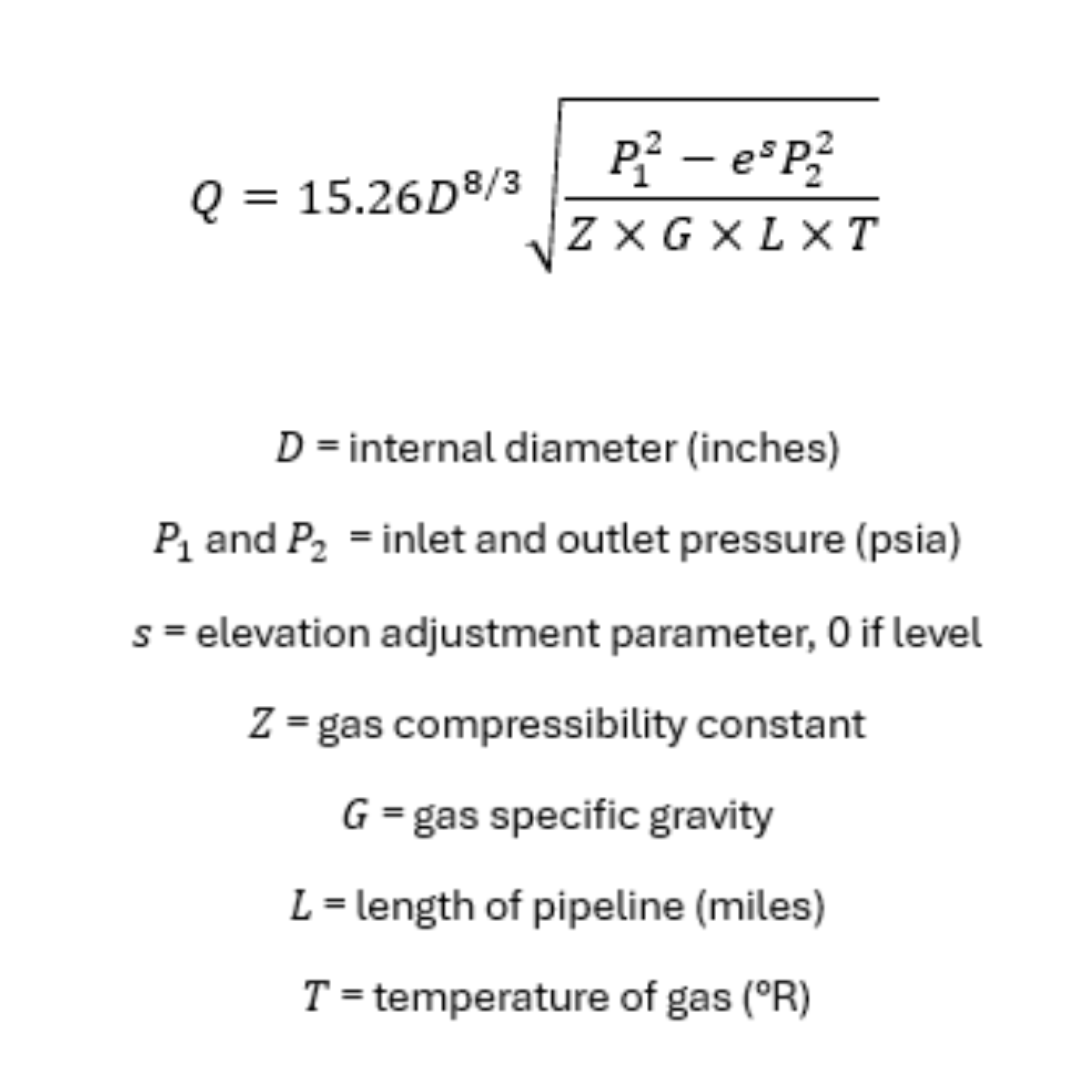

Understanding the Weymouth Equation for Gas Flow

The Weymouth equation is a fundamental tool used in the design and analysis of gas pipelines. It is used to calculate the flow rate of any gas through a pipeline, taking into account factors such as the pipeline diameter, gas pressure, gas specific gravity, and temperature. Assuming standard base conditions, the Weymouth equation is expressed as:

The Weymouth equation is integral to ensuring that pipelines are designed to handle the required flow rates efficiently and safely. By accurately predicting the gas flow, engineers can optimize pipeline diameter and material, reducing costs while maintaining safety standards.

Centrifugal Compressors in Pipeline Design

Centrifugal compressors are essential components in gas pipeline systems, used to increase the pressure of the gas to facilitate its transport over long distances. The performance of these compressors is characterized by their ability to handle varying pressures and flow rates while maintaining efficiency.

The key parameters for centrifugal compressor calculations include:

- Inlet and outlet pressures

- Flow rate

- Compressor efficiency

- Power requirements

These parameters are calculated using a combination of thermodynamic principles and empirical data, often requiring sophisticated software tools for precise results.

Role of Pipeline HUB in Optimizing Pipeline Design

The Technical Toolboxes’ Pipeline HUB is an integrated platform that offers a suite of tools designed to streamline pipeline design and analysis. Within the HUB, the Pipeline Toolbox (PLTB) provides over 250 pipeline-specific calculations, including those for the Weymouth equation and centrifugal compressor performance.

Pipeline Toolbox (PLTB):

The PLTB module within the Pipeline HUB includes a comprehensive set of tools for hydraulic calculations, stress analysis, and more. The hydraulics module, for instance, offers tools to assess upstream and downstream pressures, flow rates, and volumes, ensuring optimal and safe operating parameters for pipelines.

PLTB is designed to replace traditional, error-prone spreadsheets with a more reliable and accurate system for pipeline calculations. The software provides standardized engineering workflows, which help in reducing errors and omissions across projects. This results in significant time savings and enhanced data integrity, enabling engineers to focus on analysis and decision-making rather than manual data entry.

Modules within PLTB:

- Hydraulics: This module includes calculations such as the AGA Fully Turbulent Flow, Colebrook-White, and IGT Distribution Equation, alongside the Weymouth equation. These tools help engineers in assessing pressures, flow rates, and volumes, which are crucial for maintaining safe and efficient pipeline operations.

- Design & Stress Analysis: This includes 17 design-related modules for both gas and liquid pipelines. Calculations such as bending stress, deflection, wall thickness, and design thickness ensure pipelines are designed to industry specifications, facilitating reliable daily operations.

- Pipeline Crossings: This module addresses the impact of surface loads on buried pipes, including highway and railroad load analyses. It helps determine acceptable loads to prevent overloading and potential damage to pipeline integrity.

- Hydrotest Planning: The Hydrotest PowerTool is integrated within the PLTB to assist in planning and verifying hydrostatic pressure tests. This tool ensures compliance with regulatory standards and enhances the reliability of pipeline integrity assessments.

- Corrosion Management: PLTB includes modules for managing pipeline corrosion, leveraging the B31G methodology to determine safe operating pressure levels for corroded pipelines. This helps in deciding whether repairs are necessary to maintain pipeline safety.

- Pump and Facilities: These modules cater to fluid transport and pipeline facilities’ operational needs, including calculations for pump station piping, temperature, horsepower, and safety-related tasks to ensure smooth operations and maintenance.

By incorporating these comprehensive modules, PLTB empowers pipeline engineers to perform accurate and efficient design and operational calculations, ensuring the integrity and safety of pipeline systems.

Conclusion

The Weymouth equation and centrifugal compressor calculations are foundational to the efficient design and operation of gas pipelines. By leveraging these calculations within the Pipeline HUB, engineers can enhance the accuracy and efficiency of their projects. The HUB’s integrated platform not only streamlines these critical calculations but also facilitates better data management, compliance, and decision-making across pipeline engineering teams.

For more information on how the Pipeline HUB and its suite of tools can optimize your pipeline projects, visit Technical Toolboxes for a Pipeline HUB demo or explore the Pipeline Toolbox (PLTB).

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]