AC Corrosion on Buried Pipelines

By David Willoughby

Introduction

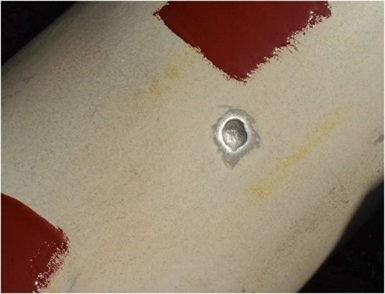

AC Corrosion on buried pipelines is corrosion initiated and spread when the pipeline is exposed to alternating current. AC voltage is the driving force for the AC corrosion which may occur at coating defects on the steel surface. The level of AC corrosion damage depends on AC current density, pipeline DC polarization, geometry of the coating defect, local soil composition, and resistivity. AC corrosion may be significant and rapid and is a threat that must be considered for both new and existing pipelines.

Mitigation Strategies

AC corrosion occurs at small coating holidays on well-coated pipelines when the pipeline suffers from induced AC voltages. As a result, an important part of the AC modeling and mitigation effort is to identify AC volts and calculate AC current densities. The primary method to determine AC current density is to calculate the current density for a circular holiday by combining equations for resistance and surface area of the circular disk with Ohm’s Law.

Where:

iAC = AC Current Density (A/m2)

VAC = pipe AC voltage to remote earth (volt)

ρ = soil resistivity (ohm-m)

d = diameter of a circular holiday

The values from this equation can be used with published data from various investigators which are:

- Does not occur at AC current densities of less than 1.9 A/ft2 (20 A/m2)

- Is unpredictable at AC current densities of 1.9 – 9.3 A/ft2 (20 – 100 A/m2)

- Can be expected at AC current densities of greater than 9.3 A/ft2 (100 A/m2)

AC corrosion rates are highest on holidays having a surface area of 1 – 3 cm^2 and decreasing with increasing cathodic protection current density.

NACE SP21424-2018-SG “Alternating Current Corrosion on Cathodically Protected Pipelines: Risk Assessment, Mitigation, and Monitoring” provides supplemental guidance for the control of corrosion for cathodically protected pipelines that are subject to AC interference. This standard practice expands on SP0177 “Mitigation of Alternating Current and Lightning Effect on Metallic Structure and Corrosion Control Systems” and introduces criteria for addressing AC Interference for cathodically protected pipelines.

The criteria detailed in Section 6 of SP21424 allow for two means of assuring that effective AC corrosion control has been achieved. One approach is for areas where the risk of AC corrosion is minimal. This approach is based on not expecting AC corrosion and demonstrating that AC corrosion is not occurring with a testing program.

The other approach is for areas where AC corrosion can be anticipated. For these areas, the criteria for effective control is based on reducing the time weighted average AC current density below a specific threshold that varies depending on the DC cathodic protection current density as follows:

- Where the DC current density is controlled to less than 1A/m2, the AC current density should be controlled to less than 100 A/m2

- Where the DC current density is not controlled to less than 1A/m2, the AC current density should be controlled to less than 30 A/m2

Challenges and Strategies in CP System Design

When we consider the dual concerns for AC corrosion and the need to control the DC current density below 1A/m2, CP system design becomes challenging. The CP system designer must understand the interaction between cathodic protection system design and its impact on AC mitigation requirements. The CP designer must consider the need to control DC current densities in AC corrosion areas.

This may require additional CP stations to reduce over-polarization, the strategic use of isolation devices to create DC current density control zones, and the use of auto-controlled rectifiers to vary current output to control DC current densities. Improving the control of DC current density can significantly reduce the amount of AC mitigation that might be required.

At higher DC current densities (protection levels) the AC interference levels should be as low as possible. If CP current density is not adequate, DC corrosion will occur and general corrosion will be enhanced by AC interference. The research agrees that AC and DC current density are the primary parameters to assess the AC corrosion likelihood.

More on AC Mitigation

For more information regarding this blog topic, read our AC Interference Mitigation blog or join me in our Cathodic Protection for Buried Pipelines Training.

training. You can also contact me, the author, David Willoughby, at [email protected]

Suggested Post

The Network Modeling Tool Gas Engineers Didn’t Know They Needed

The Network Modeling Tool Gas Engineers Didn’t Know They Needed By Kesley Price You’ve outgrown your spreadsheets, now [...]

The Trusted Tool Gas Engineers Didn’t Know They Were Missing

Do You Really Know What’s Flowing Through Your Pipes? The Trusted Tool Gas Engineers [...]

2026 API Compliance: What You Need to Know

2026 API Compliance: What You Need to Know By Kesley Price New rules. Tougher [...]